There are various industrial valves used in our industrial pipelines,like butterfly valves, gate valves, ball valves, check valves, globe valves, control valves, safety valves, air valves,etc. some are used as connect, cut off the medium flow, some are used to regulate, control the medium flow. While it becomes important for us to know how to select the proper industrial valves for our pipelines, so today we are going to introduce you how to select a proper industrial valves:

Industrial valves selection guides:

Before selecting the proper industrial valves, we should know the performance of the mediums, the flow characteristics, and the temperature, pressure, flow rate and flow volume. Then combined with other factors like manufacturing process, operation and safety, to select the proper type of industrial valve, the right structure style, and the proper model specifications.

The shape of the valve opening and closing parts and the valve flow channel make the valve have certain flow characteristics. We should take a consideration about that when selecting a industrial valve.

1. industrial valves used to cut off and connect the mediums usually select those industrial valves with small flow resistance and straight through flow channels. Those industrial valves include gate valves, globe valves and plunger valves. The downward closed valve is less selected due to their tortuous flow path and higher flow resistance than other industrial valves. However, closed industrial valves can also be used where higher flow resistance is allowed.

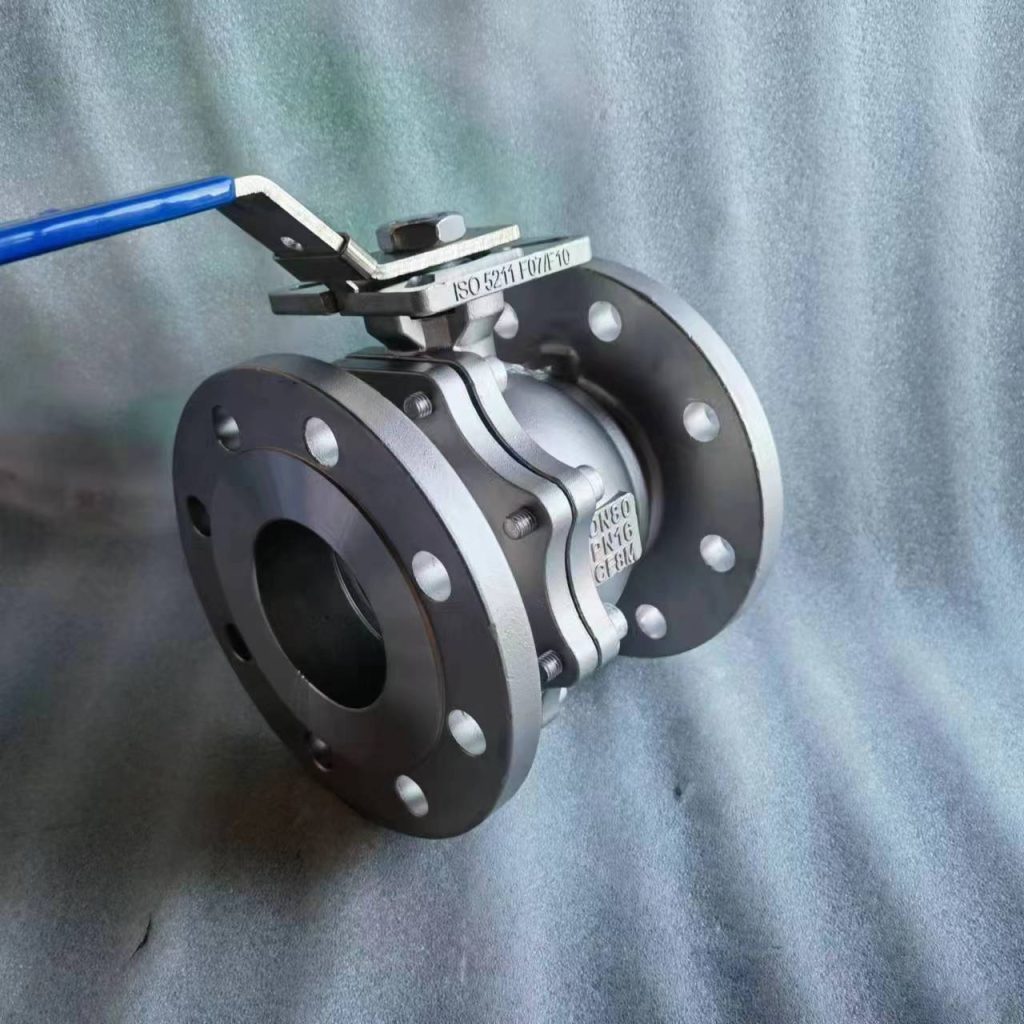

2. Industrial valves used to control the medium flow usually select those industrial valves which are easy to adjust the flow rate,such as regulating valves, throttle valves and plunger valves, because for those valves, the size of their valve seat is proportional to the stroke of the opening and closing part. Rotary valve(like plug valves, ball valves and butterfly valves) can also be used for throttling control. While those valves are only used for limited valve diameters. In most cases, people usually change the shape of the valve disc of the globe valve for throttling. But it is extremely unreasonable to change the opening height of the gate valve or globe valve to achieve the throttling effect. Because when the medium in the pipeline is in a throttled state, its flow rate is very high, its sealing surface is easily washed and worn and its cutting and sealing effect will be lost. Similarly, it is unreasonable to use throttle valves as cutting off device.

3. For those industrial valves used for reversing and distributing, those industrial valves can have two or more passengers, are suitable to select plug valves and ball valves. In some cases, two or more some other types industrial valves can be properly connected to be used for reversing and distributing the flow of the mediums.

4. If the medium contains suspended particles, it is most suitable to use those industrial valves with wiping effect, such as flat gate valves and knife gate valves, whose opening and closing part slides along the sealing surface.

for more information about any industrial valves, kindly contact us: