Butterfly valve is one important industrial device for pipeline systems. with its simple structure feature and low manufacturing cost, butterfly valves are popular in various projects. for different structure, butterfly valves can be divided into concentric butterfly valves and eccentric butterfly valves. and eccentric butterfly valves can be divided into single eccentric butterfly valves, dual eccentric butterfly valve( also known as high performance butterfly valve sometimes), triple offset butterfly valve(or called triple eccentric butterfly valves). when we mentioned resilient seated butterfly valves, usually we mean resilient seated concentric butterfly valves, when we need metal seated butterfly valves, general we mean eccentric butterfly valves. today we are going to introduce the differences between resilient seated butterfly valves and metal seated butterfly valves.

The butterfly valve is a versatile and efficient industrial valve widely used in various industries for controlling the flow of fluids. Two common types of butterfly valves are the resilient seated butterfly valve and the metal seat butterfly valve. Although they serve the same purpose, these butterfly valves differ significantly in terms of design, materials, and applications. In this product description, we will delve into the key differences between these two types of butterfly valves.

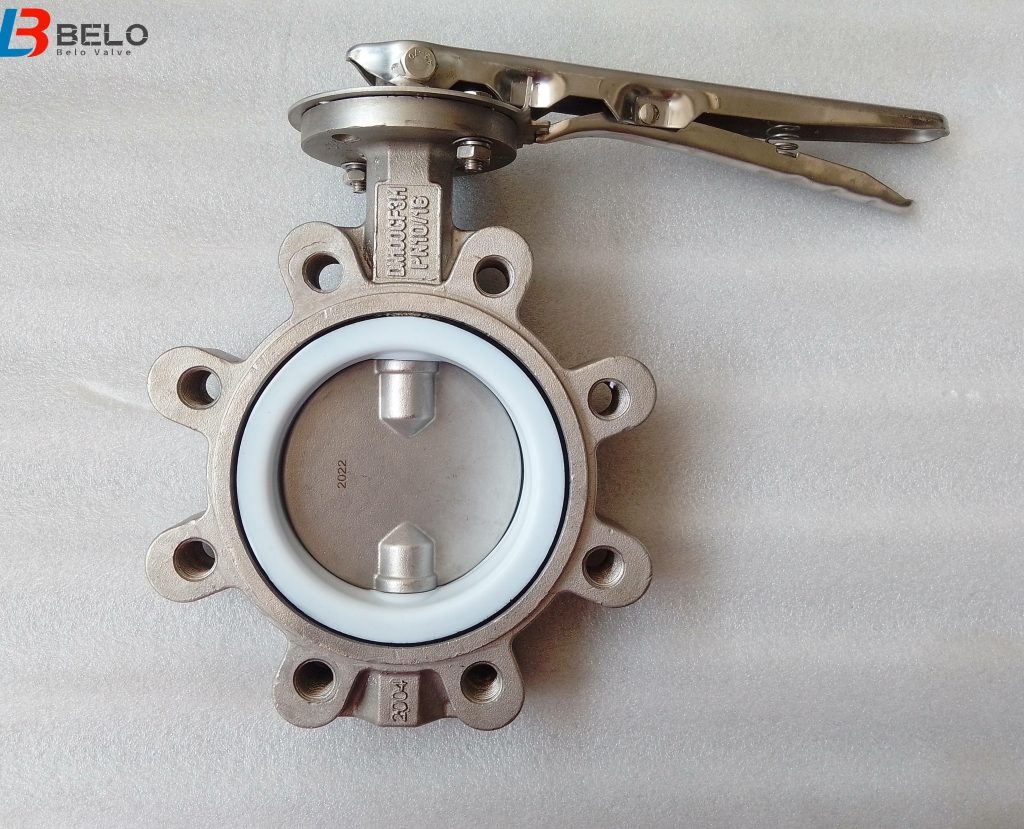

About resilient seated butterfly valve:

-Specification of resilient seated butterfly valve: The resilient seated butterfly valve is a lightweight and cost-effective butterfly valve. It features a rubber-lined body that provides excellent sealing performance and reduces the risk of leakage. These resilient seated butterfly valves are available in a range of sizes, typically ranging from 2 inches to 48 inches. The resilient seat material is often EPDM, Nitrile, or Buna-N, and PTFE. Pressure ratings can vary, but they commonly range from 150 psi up to 300 psi.

-Material options of resilient seated butterfly valve: The body of resilient seated butterfly valves is typically made of cast iron, ductile iron, or stainless steel. The disc, which controls the flow, is usually composed of stainless steel or a similar robust material like ductile iron. The resilient seat is typically made of elastomers such as EPDM,PTFE for compatibility with a wide range of fluids.

-Usage of resilient seated butterfly valve: Resilient seated butterfly valves are commonly used in applications that require bubble-tight shutoff and moderate operating pressures. They find applications in industries such as water treatment, chemical processing, HVAC systems, and wastewater management. These valves are well-suited for handling fluids such as water, air, gases, and low-viscosity liquids.

-Features of resilient seated butterfly valve: 1. Cost-effective: Resilient seated butterfly valves offer an economical solution for controlling flow, especially in large-scale piping systems.

2. Excellent sealing performance: The rubber-lined body of resilient seated butterfly valve ensures a tight seal, reducing the risk of leakage.

3. Lightweight: These resilient seated butterfly valves are lightweight compared to other types, making them easy to install and handle.

4. Low maintenance: The simple design and robust materials used in construction make resilient seated butterfly valves low maintenance and long-lasting.

5. Versatility: With a range of sizes, pressure ratings, and seat materials, these resilient seated butterfly valves can accommodate various fluid and pressure requirements.

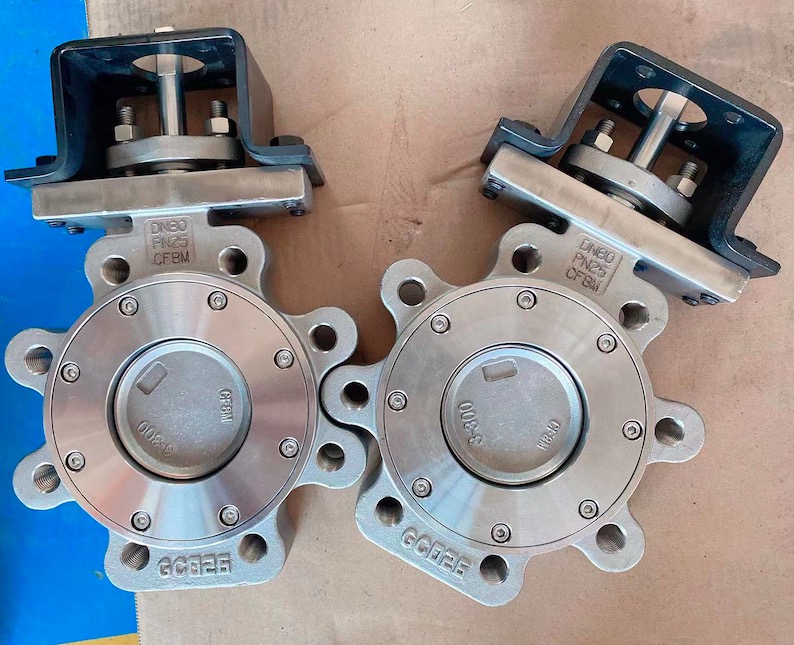

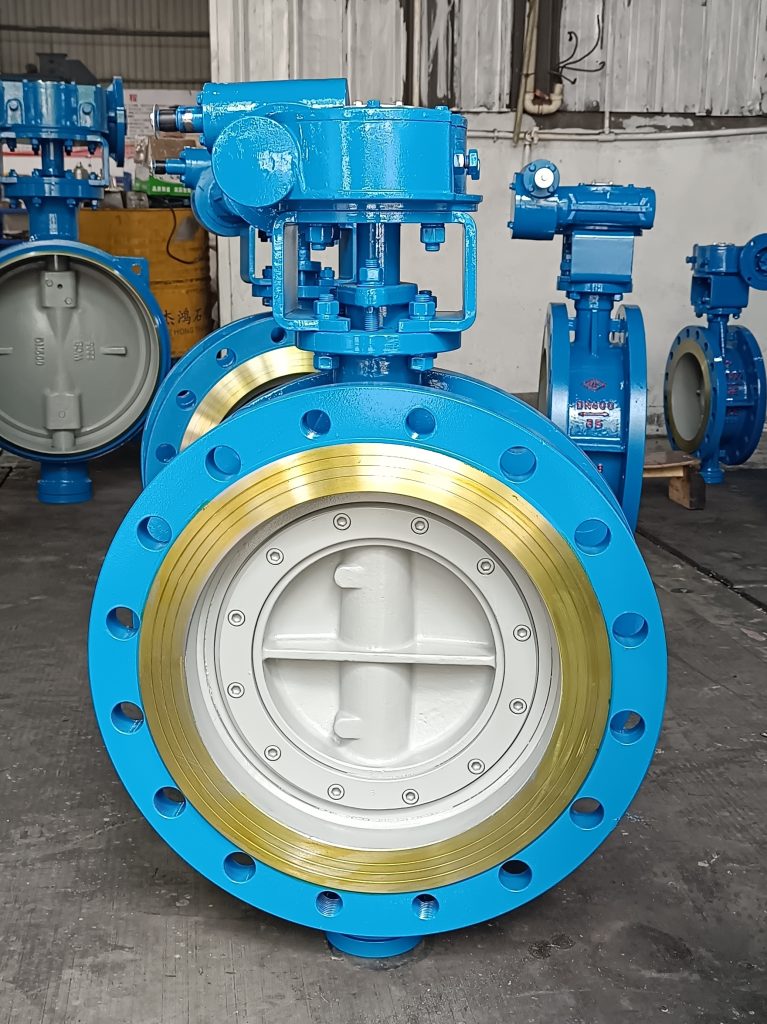

About metal seated butterfly valve:

-Specification of metal seated butterfly valve: Metal seat butterfly valves are primarily designed for high-temperature and severe service applications. They are available in larger sizes, typically ranging from 24 inches up to 120 inches or even larger. The pressure ratings of metal seat butterfly valves are generally higher, ranging from 150 psi up to 600 psi.

-Material options of metal seated butterfly valve: The body and disc of metal seat butterfly valves are commonly made of materials such as stainless steel, carbon steel, or exotic alloys for enhanced strength and resistance to corrosion. The seat, unlike the resilient seated version, is typically made of metal, providing greater durability and resistance to high temperatures.

-Usage of metal seated butterfly valve: Metal seat butterfly valves are suitable for high-pressure and high-temperature applications, particularly in industries such as oil and gas, power generation, petrochemicals, and refining. These valves can handle abrasive and corrosive media, making them ideal for challenging environments.

-Features of metal seated butterfly valve: 1. High-temperature resistance: Metal seat butterfly valves can withstand extreme temperatures, making them suitable for applications involving steam and hot gases.

2. Robust construction: The use of sturdy and corrosion-resistant materials ensures durability even in demanding environments.

3. High pressure rating: These metal seated butterfly valves can handle higher pressures, making them suitable for applications with elevated pressure requirements.

4. Tight shutoff: Metal seats of metal seated butterfly valve provide a secure sealing mechanism, enabling precise flow control and minimal leakage.

5. Suitable for harsh media: Metal seat butterfly valves can handle abrasive and corrosive fluids, expanding their usability in various industries.

In conclusion, while both resilient seated butterfly valves and metal seat butterfly valves serve the same purpose of flow control, their design, materials, and applications differ significantly. Resilient seated butterfly valves are cost-effective and suitable for moderate-pressure applications, while metal seat butterfly valves excel in high-temperature and harsh service conditions. Understanding these differences allows users to select the appropriate butterfly valve based on their specific requirements and industry demands.