Butterfly valve is one popular industrial valve, whose plate rotate 90° around the valve shaft to realize the opening and closing of the butterfly valve to control, regulate the media flow. while with different structural design, butterfly valves can be divided into eccentric butterfly valves and concentric butterfly valves(which is also called center line butterfly valves).

Belo Valve is one direct manufacturer, wholesaler, exporter for concentric butterfly valves, wafer concentric butterfly valves, lugged style concentric butterfly valve, flanged concentric butterfly valves, with body material cast iron, ductile iron, carbon steel(WCB) and stainless steel, sealing seat material EPDM or PTFE, and plate material ductile iron or stainless steel. the diameter range of our concentric butterfly valve can be DN50-DN1200mm, and the nominal pressure range of our concentric butterfly valves can be PN10, PN16, PN25. if you need any inquiries about those concentric butterfly valves, or you need some detailed datas about any concentric butterfly valves. you can contact us freely.

The ductile iron concentric flanged resilient seated butterfly valve is a high-performance valve designed for reliable and efficient flow control in various industrial applications. It offers a cost-effective solution with excellent durability, long service life, and low maintenance requirements.

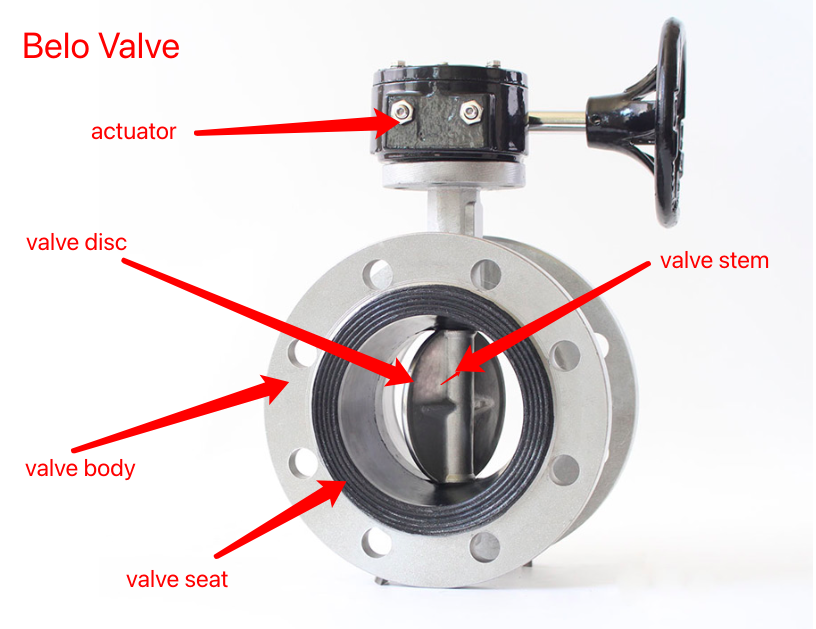

Components of concentric flanged resilient seated butterfly valve and their material options:

the ductile iron concentric flanged resilient seated butterfly valve mainly consists of the valve body, valve plate, valve shaft, valve seat, operator(hand lever, hand wheel, actuators).

The valve body and plate of concentric flanged resilient seated butterfly valve are made of high-quality ductile iron, known for its strength and corrosion resistance. The valve seat of concentric flanged resilient seated butterfly valve, typically made of EPDM or NBR rubber, or PTFE, ensures a tight seal and provides resistance to wear and chemicals. The shaft of concentric flanged resilient seated butterfly valve, often made of stainless steel, connects the actuator and disc, allowing for smooth operation and precise control.

Additionally, the concentric flanged design features bolt holes around the valve’s circumference, providing secure and easy installation. The flange material can be customized to suit specific project requirements, commonly made of carbon steel or stainless steel.

Working principle of ductile iron concentric flanged resilient seated butterfly valve:

The working principle of the ductile iron concentric flanged resilient seated butterfly valve revolves around the rotation of the valve plate, controlled by the hand lever, hand wheel or actuators. When the concentric flanged resilient seated butterfly valve is in the closed position, the plate seals against the valve seat, preventing any leakage. As the actuator rotates, the valve plate opens, allowing the fluid or gas to flow through the concentric flanged butterfly valve. The precision engineering of the concentric flanged resilient seated butterfly valve ensures a tight seal even under high-pressure conditions.

Advantages of ductile iron concentric flanged resilient seated butterfly valve:

1. Versatility: The concentric flanged resilient seated butterfly valve’s versatile design allows it to be used for a wide range of applications, including water treatment plants, chemical processing, HVAC systems, and more.

2. Excellent Flow Control: The concentric design of the ductile iron concentric flanged resilient seated butterfly valve offers unrestricted flow, minimizing pressure drop and ensuring smooth and efficient operation.

3. Resilient Seat: The resilient seat of the concentric flanged butterfly valve provides a tight seal, preventing any leakage and reducing the risk of contamination. It also offers resistance to chemicals and temperature variations, making it suitable for various challenging environments.

4. Corrosion Resistance: The ductile iron construction of the concentric flanged resilient seated butterfly valve provides excellent resistance to corrosion, ensuring a long service life even in harsh operating conditions.

5. Low Maintenance: The concentric flanged butterfly valve’s simple yet robust construction requires minimal maintenance, reducing downtime and overall operating costs.

Where those ductile iron concentric flanged resilient seated butterfly valves are used:

The ductile iron concentric flanged resilient seated butterfly valve can find wide applications in numerous industries:

1. Water and Wastewater: The ductile iron concentric flanged resilient seated butterfly valve is widely used in water treatment plants for regulating water flow, allowing for effective distribution and control in the network.

2. Chemical Processing: The ductile iron concentric flanged resilient seated butterfly valve’s corrosion-resistant materials and reliable sealing make it suitable for handling various chemicals, ensuring safe and efficient processing.

3. HVAC Systems: The ductile iron concentric flanged resilient seated butterfly valve helps regulate the flow of air, water, or steam in heating, ventilation, and air conditioning systems, maintaining desired temperature and comfort levels.

4. Industrial Process Control: The ductile iron concentric flanged resilient seated butterfly valve can be utilized to control the flow of fluids or gases in industrial processes, allowing for precise adjustments and optimization.

The ductile iron concentric flanged resilient seated butterfly valve offers exceptional performance, longevity, and versatility. Its high-quality components, resilient seat, and corrosion resistant materials make it an ideal choice for various applications, providing reliable flow control and contributing to the efficiency and safety of industrial operations.

Contact Belo Valve for inquiries about concentric flanged resilient seated butterfly valves: