Gate valve(sluice valve) and globe valve are two widely used industrial valves in water pipelines systems, oil and gas industry, pharmacy industry, food industry, fire protection pipe line networks, etc. This article is going to show you the difference between gate valve(sluice valve) and globe valve, which may help you to decide what kind of industrial valves should be used in your projects:

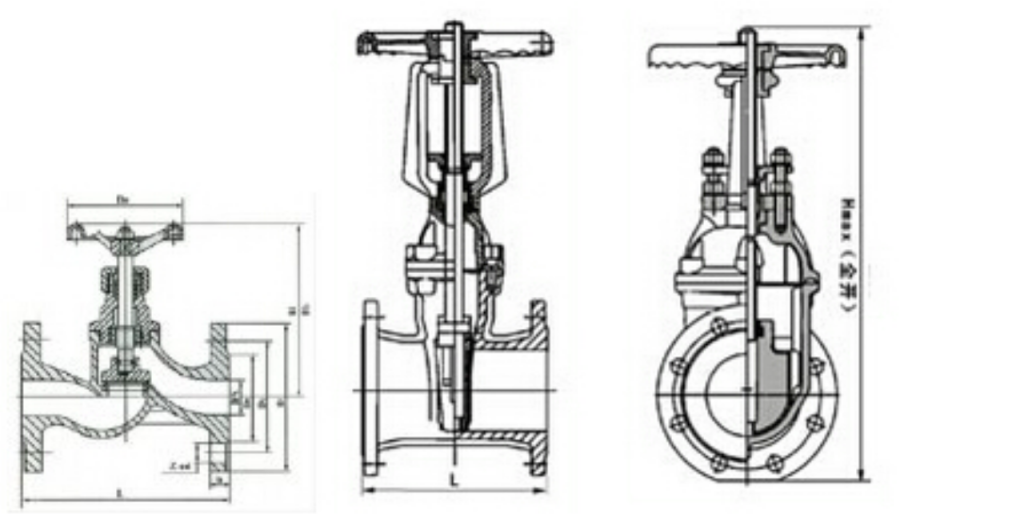

1. the difference between gate valve(sluice valve) and globe valve in structure:

The structure of the gate valve(sluice valve) will be more complicated than that of the globe valve. From the perspective of appearance, the gate valve(sluice valve) is taller than the globe valve and the globe valve is longer than the gate valve(sluice valve), if their diameters are the same.

The gate valves( sluice valve) are also divided into rising stem gate valves and non rising stem gate valves, but the globe valves don’t have the non rising stem glove valve and rising stem globe valve.

2. the difference of gate valve(sluice valve) and globe valve in working principles:

The gate valve(sluice valve) only has two states of fully open or fully closed to cut off the flow, the opening and closing stroke of the valve disc is very large, and the opening and closing time of gate valve is long, the opening and closing stroke of the globe valve will be smaller, and the disc of the globe valve can be stopped at a certain position and so the globe valve can be used for flow regulation; the gate valve(sluice valve) can be installed in any direction without the flow direction requirements of mediums, on the other hand, the globe valve has the settled flow direction of the mediums, the mediums can only go inside from the lower side and go out from the upper side.

3. the difference between gate valve(sluice valve) and globe valve in performance:

Because the gate valve(sluice valve) can only be full opened and fully closed, when the gate valve is fully opened, the medium flow resistance in the valve body channel is almost zero, so the opening and closing of the gate valve(sluice valve) will be very labor-saving, but the valve disc is far away from the sealing surface, so the opening and closing time is longer; the globe valve can be used for both cutting off the mediums and regulating the flow rate. The fluid resistance of the globe valve is relatively large, and it is more laborious to open and close, but because the distance between the valve plate and the sealing surface is short, so the opening and closing stroke is short.

4. the difference between gate valve(sluice valve) and globe valve in sealing:

The sealing surface of the globe valve is a small trapezoidal side of the valve core(specifically depending on the shape of the valve core). Once the valve core falls off, it is equivalent to the valve closing(if the pressure difference is large, the closure is not strict, but the checking effect is not bad). the gate valve(sluice valve) is using the side surface of the valve core plate to do the sealing, the sealing effect is not as good as that of the globe valve. Not like the globe valve, if the valve core of the gate valve falls off, it won’t be equivalent to the valve closing.

Belo Valve is one more than 15 years professional Chinese manufacturer for industrial valves, like soft seal gate valves, hard seal gate valves, rising stem gate valves, non rising stem gate valves, center line wafer butterfly valves, flange butterfly valves, flange telescopic butterfly valves, lug type butterfly valves, soft seal butterfly valves, hard seal butterfly valves, swing check valves, butterfly wafer check valves, rubber disc check valves, ball type check valves, bellows globe valves, electrical globe valves, soft seal ball valves, hard seal ball valves, stainless steel high pressure ball valves, all welded ball valves, grooved fire fighting valves,( including grooved gate valves, grooved butterfly valves, grooved check valves, grooved strainers, etc) , hydraulic control valves, strainers, and pipe rubber joints, with body material: ductile cast iron, cast iron, cast steel/WCB, forge steel, stainless steel, with standard like GB, DIN F4, DINF5, API 600, API 6D, BS, JIS, KS, GOST.

for valve price and technical parameters, kindly contact us.