A flanged Y type strainer cast iron body bolted bonnet is a type of industrial filtration device designed to remove solids from a fluid or gas pipeline. It is called a “flanged” strainer because it has flanges on each end, which allows for easy installation and connection to the pipeline using bolts or screws. The “Y” shape of the strainer refers to its internal structure, resembling the letter “Y.”. the body material of flanged Y type strainers bolted bonnet can be cast iron, ductile iron, carbon steel(WCB), stainless steel.

The purpose of a flanged Y type strainer bolted bonnet is to trap and collect solid particles, debris, and other impurities present in the fluid or gas before it flows downstream. This helps prevent damage to sensitive equipment, such as pumps, valves, meters, and heat exchangers, and ensures the smooth operation of industrial processes.

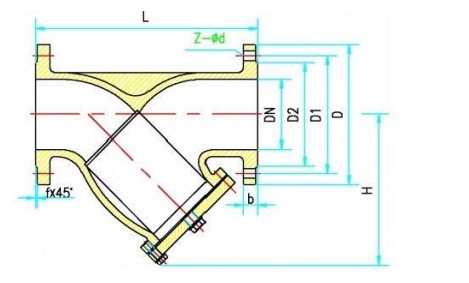

the technical drawing of flanged Y type strainer bolted bonnet:

The design of a flanged Y type strainer bolted bonnet consists of a main body with an inlet and outlet connected by a Y-shaped screen or straining element. the body material of flanged Y type strainer can be cast iron, ductile iron, cast steel WCB, stainless steel. the customer can choose different body material for flanged y type strainer according to real working conditions. The straining element can be made of various materials, such as stainless steel, brass, or other corrosion-resistant alloys, depending on the specific application requirements. The Y shape of the straining element provides a larger filtration area compared to other strainer designs, allowing for better flow capacity and reduced pressure drop.

Standard options of flanged Y type strainer bolted bonnet:

The cast iron flanged Y type strainer with a bolted bonnet adheres to stringent industry standards to ensure optimum performance and compatibility. Commonly adopted standards for this flanged Y type strainer include the DIN standard, ASTM/ANSI/API standard.

Why flanged Y type strainers with cast iron GG25 body material are better compared with flanged Y type strainers with other body material:

For those flanged y type strainer bolted bonnet, their body material can be cast iron, ductile iron, carbon steel, stainless steel, while still, cast iron GG25 flanged Y type strainers bolted bonnet are widely used compared with other material flanged Y type strainers. this article is going to introduce why flanged Y type strainers bolt bonnet with cast iron GG25 body material are popular:

Strength and Durability: The cast iron body of flanged Y type strainer provides exceptional strength, making it ideal for handling high-pressure and high-temperature applications.

Corrosion Resistance: Cast iron for Y type strainer flanged is known for its inherent resistance to corrosion, ensuring long-term operation even in harsh environments.

Cost-Effective: Cast iron in the cast iron flanged Y type strainer is a cost-effective material choice without compromising on performance, making it a preferred option for budget-conscious projects.

Installation Direction of Y Type Strainer:

The cast iron GG25 flanged Y type strainer with bolted bonnet owes its name to its structural design, which resembles the letter “Y.” This flanged Y type strainer offers a streamlined flow path, ensuring efficient filtration and minimized pressure drop. When installing a flanged Y type strainer, it is crucial to consider the correct flow direction. The inlet of the flange Y type strainer should align with the main flow direction, allowing the Y-shaped screen to effectively capture impurities and debris from the fluid.those flanged Y type strainer can be installed in the pipeline systems horizontally or vertically, just to make sure the flow direction of the media is following the arrow direction casted on the outside of the body of flanged Y type strainer.

Where cast iron GG25 flanged Y Type Strainers bolted bonnet are Usually Installed:

flanged Y type strainers cast iron GG25 body find extensive applications across a range of industries, including oil and gas, chemical processing, water treatment, power generation, and HVAC. Their versatile design and robust construction make them suitable for both industrial and commercial use. Here are some common installation locations for flanged Y type strainers:

Pump Protection: DIN cast iron GG25 flanged Y type strainers are often installed upstream of pumps to prevent the entry of solid particles, debris, and foreign matter that could damage pump components.

Pipeline Protection: These cast iron flanged Y type strainers are installed in pipelines to safeguard downstream equipment, such as valves, meters, and flow control devices, from potential damage caused by particulate matter.

Cooling Systems: cast iron GG25 Y type strainers are used in cooling systems to filter out impurities, preventing clogging and minimizing heat exchanger fouling, thereby improving overall system efficiency.

Water Treatment: GG25 Y type strainers play a crucial role in water treatment plants, ensuring the removal of particles such as sand, sediment, and algae before the water enters the treatment process.

Process Industry: DIN cast iron GG25 flanged Y type strainers are employed in various process industries to maintain the purity of process fluids, safeguarding sensitive equipment and promoting smooth operation.

In conclusion, the DIN/ASTM cast iron GG25 flanged Y type strainer with a bolted bonnet is a reliable and versatile strainer choice. Its conforming to industry standards, cast iron body material features, along with proper installation and strategic placement, guarantee efficient and effective filtration across diverse applications. Understanding the importance and advantages of these cast iron GG25 flanged Y type strainers can significantly contribute to the smooth operation and longevity of industrial systems.

Belo Valve is one OEM wholesale exporter for DIN cast iron GG25 flanged Y types strainer with diameter DN15-DN500, PN10 and PN16, and ASTM A126 cast iron GG25 flanged Y type strainer, 2″-20″, 125LB, if you are looking for some cast iron Y type strainers, you can contact us direct.