Globe valve, also known as stop valve, cut-off valve, is a forced sealing industrial valve. so when the globe valve is closed, extra pressure must be applied to the valve disc to force the sealing surface not to leak. when the medium enters the globe valve from the bottom of the valve disc, the resistance that the operating force needs to overcome is the friction between the valve stem and packing, and the thrust generated by the pressure of the medium. the force to close the globe valve is greater than the force to open the globe valve. so the diameter of the valve stem of the globe valve must be large, otherwise the valve stem of the globe valve may fail to work.

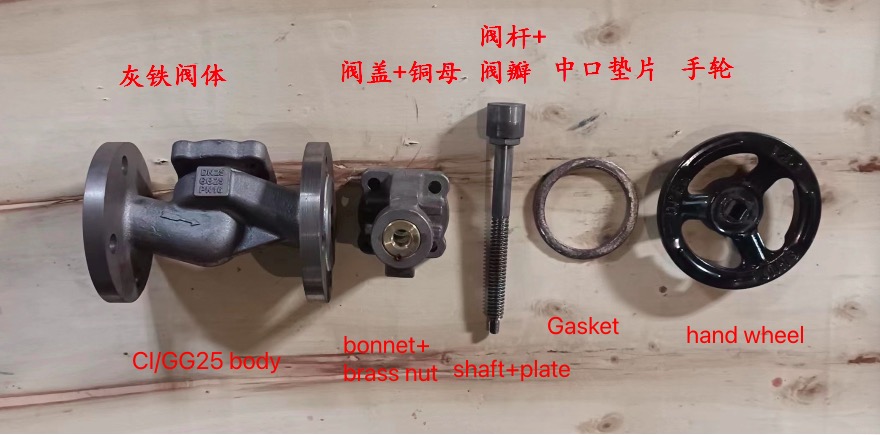

A globe valve is a type of industrial valve used to regulate the flow of fluid through a pipeline. the globe valve consists of the valve body(can be cast iron, ductile iron, carbon steel, or stainless steel), the valve bonnet, valve stem(or also called valve shaft) a movable disk (or plug) and a stationary ring seat, and the operating device( usually is cast iron or steel hand wheel) . The disk is connected to the stem, which is operated by a handwheel or actuator. When the stem is turned, the disk moves up or down, allowing or restricting the flow of fluid.

Type of globe valves:

According to different body material: with different body material used, globe valve can be divided into cast iron globe valves, ductile iron globe valves, WCB/carbon steel/cast steel globe valves and stainless steel globe valves, and other special alloy globe valves

According to different end connect design: with different end connect, globe valves can be divided into flanged type globe valve, threaded globe valve and welded globe valve.

According to different sealing structure: with different sealing structure design, globe valves can be divided into gland sealing globe valve and bellows sealing globe valves.

According to different channel direction design: with different channel direction, globe valves can be divided into the T-pattern globe valve, Y-pattern globe valve, and angle globe valve. The T-pattern globe valve is the most common type and is used for general applications. The Y-pattern globe valve is used for high-pressure applications, as it provides better flow characteristics. The angle globe valve is used in applications where space is limited.

Today we are going to introduce the flanged cast iron globe valve gland sealing:

Type of valve: globe valve/stop valve

Nominal diameter range: DN15-DN200

Nominal pressure: PN/10/PN16/PN25

Standard: DIN

Body and bonnet material: cast iron, gray cast iron,CI,GG25

Disc: stainless steel

Shaft: stainless steel

Seat: stainless steel

Packing: graphite

sealing structure: gland sealing

Operating: manual hand wheel

Applicable media: water, steam, oils, corrosive medias.

Flanged Cast iron globe valve uses: manual flanged cast iron globe valves are widely used in water supply and drainage, gas, electric power, metallurgy, petroleum, chemical industry, textile and urban construction and other industries.

cast iron Globe valves gland sealing work by using the movement of the valve disk to control the flow of fluid. When the valve disk is in the fully open position, the flow is unrestricted. As the disk is closed, the flow is gradually restricted, allowing for precise control of the flow rate. The disk and seat design of a globe valve also provides a tight seal when the cast iron globe valve is closed, preventing any leakage.

Cast iron globe valves gland sealing are commonly used in applications where durability and resistance to corrosion are important. They are often used in industries such as water treatment, oil and gas, and chemical processing. Cast iron globe valves gland sealing are suitable for both high-pressure and low-pressure applications and can handle a wide range of temperatures.