butterfly valve is a type of quarter-turn industrial valve that is used to control the flow of fluids in a pipeline. usually a butterfly valve consists of a valve disc, which is connected to a rod or shaft in the center of the valve body, and rotates 90 degrees to open or close the butterfly valve. When the butterfly valve is fully opened, the valve disc is parallel to the flow, allowing for unrestricted flow. When the butterfly valve is closed, the valve disc is perpendicular to the flow, providing a tight shut-off.

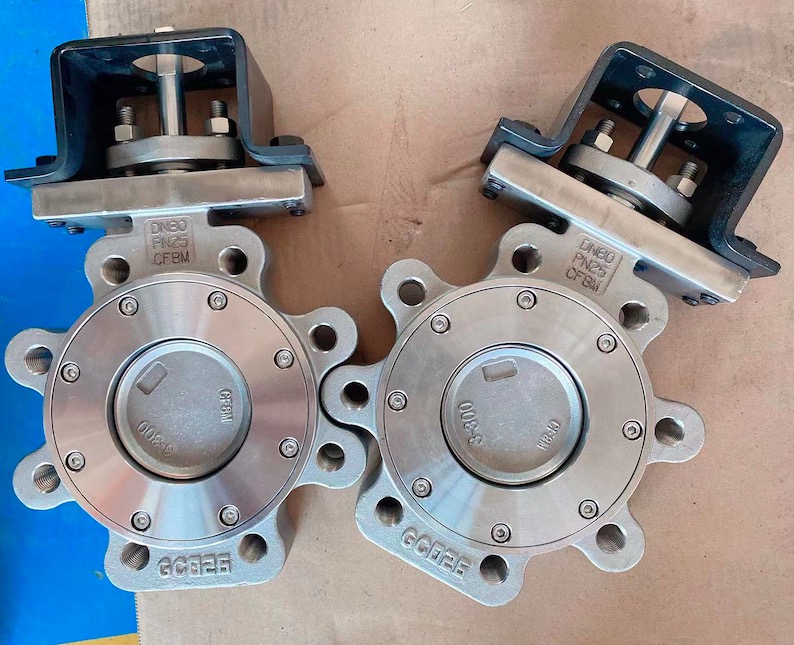

How a butterfly valve looks like:

Common types of butterfly valve:

There are several types of butterfly valves, including:

1. Concentric Butterfly Valve: the concentric butterfly valve is the most common type of butterfly valve, where the valve disc is centered in the valve body. It provides a bubble-tight shut-off and is suitable for a wide range of applications.

2. Double Offset Butterfly Valve: In this type of double offset butterfly valve, the valve disc is offset from the centerline of the valve body and the shaft. This design reduces friction and wear on the sealing surfaces, allowing for a longer service life and better sealing performance.

3. Triple Offset Butterfly Valve: This triple offset butterfly valve has the disc offset from the centerline of the valve body and the shaft, but with an additional offset in the seat. This creates a cone-shaped sealing surface, providing a tight shut-off even in high-pressure and high-temperature applications.

4. High-Performance Butterfly Valve: These high performance butterfly valves are designed for demanding applications that require higher pressure ratings, tighter shut-off, and better control. They often have features such as metal seats, fire-safe designs, and extended temperature ranges.

5. concentric Wafer Butterfly Valve: This type of wafer concentric butterfly valve is designed to fit between two flanges and is held in place using bolts or lugs. It is lightweight and compact, making it suitable for space-constrained installations.

6. concentric Lug Butterfly Valve: Similar to the concentric wafer butterfly valve, the concentric lug butterfly valve also fits between two flanges, but it has threaded lugs on the valve body. These lugs allow for easy installation and removal of the butterfly valve without disrupting the entire pipeline.

7. concentric Flanged Butterfly Valve: This type of concentric flanged butterfly valve has flanges on both ends, allowing for easy installation and connection to the pipeline using bolts.

8. Grooved Butterfly Valve: These butterfly valves have grooved ends, which are compatible with grooved pipe couplings. They are commonly used in fire protection systems and other applications that require quick and easy installation.

Today we are going to introduce the manual lever operated stainless steel concentric lugged soft sealing butterfly valve:

A stainless steel concentric wafer lugged butterfly valve is a type of butterfly valve that is designed with a concentric disc and a wafer-style body. It is constructed using stainless steel, which provides excellent corrosion resistance and durability, making it suitable for a wide range of applications.

Product name: stainless steel butterfly valve/concentric butterfly valve/concentric lugged butterfly valve/manual butterfly valve/soft sealing butterfly valve/PEDM lined concentric butterfly valve

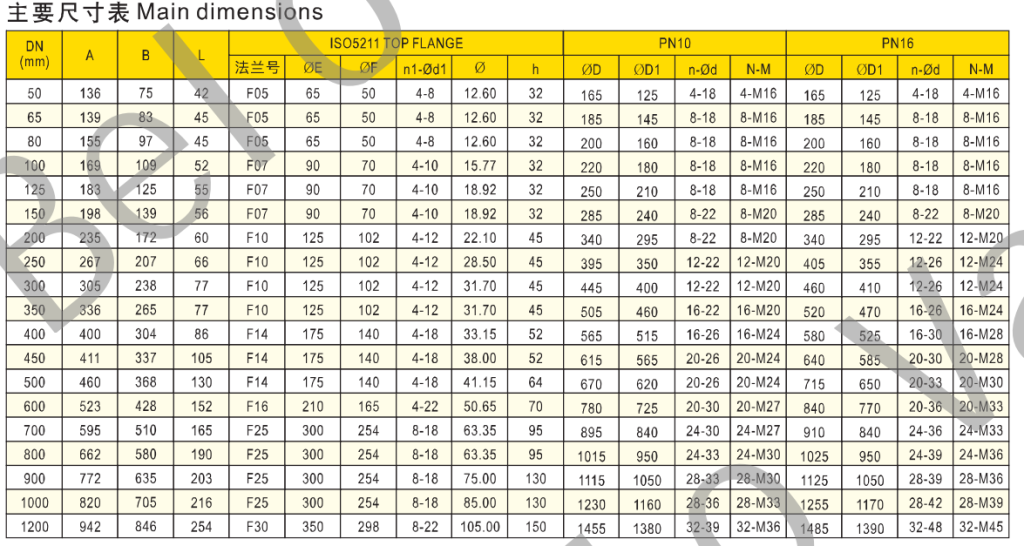

diameter range: DN50mm-DN1200mm

pressure rate: PN10 and PN16.

Body material/plate/stem material: stainless steel.

valve seat material: NBR. EPDM, PTFE.

end connect: lugged type.

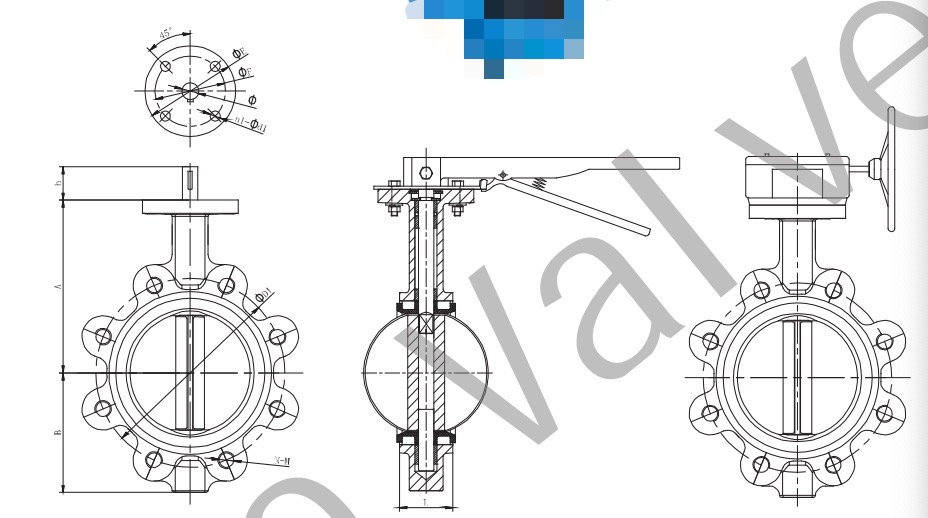

technical drawing for concentric lugged soft sealing butterfly valve:

Main dimensions for concentric lugged soft sealing butterfly valve:

Key advantages of concentric wafer lugged butterfly valve, stainless steel butterfly valve, manual butterfly valve:

1. Design: The concentric lugged butterfly valve features a concentric disc design, where the disc is centered in the middle of the valve body. This design allows for a bubble-tight shut-off and ensures minimal pressure drop across the valve.

2. Wafer style Body: This concentric butterfly valve has a wafer style body, which means it is sandwiched between two flanges and held in place using bolts or lugs. This design allows for easy installation and removal without the need for additional pipe support.

3. Stainless Steel Construction: The valve body is made from stainless steel material, which offers excellent resistance to corrosion, chemicals, and high temperatures. This makes it suitable for a wide range of applications, including industrial processes, water treatment, chemical handling, and food processing.

4. Butterfly Disc: This stainless steel concentric lugged butterfly valve features a disc that is mounted on a shaft in the center of the valve body. The disc rotates 90 degrees to control the flow of fluids. When the butterfly valve is fully open, the disc is parallel to the flow, allowing for unrestricted flow. When the butterfly valve is closed, the disc is perpendicular to the flow, providing a tight shut-off.

5. Lugged Design: The valve has lugs or threaded holes on the valve body, which allow for easy installation and secure connection to the pipeline. The lugged design also allows for the valve to be easily removed or replaced without disrupting the entire pipeline.

6. Versatile Applications: The stainless steel concentric wafer lugged butterfly valve is suitable for a wide range of applications, including water and wastewater treatment, HVAC systems, chemical processing, food and beverage industries, pharmaceuticals, and more.

7. Easy Operation and Maintenance: the stainless steel concentric wafer lugged butterfly valve is designed for easy operation, with a simple 90-degree rotation to open or close the valve. It also requires minimal maintenance due to its durable stainless steel construction.