API 609 fully lugged high performance butterfly valve Class 150

Brief introduction of API 609 fully lugged high performance butterfly valve

This API 609 lug high performance butterfly valve adopts a double eccentric/dual offset structure design, which makes that HP butterfly valve have less friction and less torque when opening and closing, so as to achieve faster response speed and longer service life. at the same time, the lugged style design of that API HP butterfly valve Class 150 can achieve quickly installation and disassembly, which is also convenient for maintenance and inspection.

12 month warranty!!

- Strict inspections before delivery !

- Direct factory price !

- Fast delivery !

Product Name: API 609 Fully lugged high performance butterfly valve Class 150

Model: HPBFV-150LB

Brief introduction of API 609 fully lugged high performance butterfly valve

API 609 full lug type high performance butterfly valve is also called API 609 lug type high performance double eccentric butterfly valve, is one kind of fluid control equipment. due to its simplicity, compactness, flexible operation and low manufacturing cost, that API high performance butterfly valve lug style is widely used in various industrial pipeline systems, especially suitable for the control of high temperature, high pressure and strongly corrosive medias. This API 609 lug high performance butterfly valve adopts a double eccentric/dual offset structure design, which makes that HP butterfly valve have less friction and less torque when opening and closing, so as to achieve faster response speed and longer service life. at the same time, the lugged style design of that API HP butterfly valve Class 150 can achieve quickly installation and disassembly, which is also convenient for maintenance and inspection.

Specifications of API 609 high performance butterfly valve:

Diameter range: NPS 2.5″-24″

Pressure rate: Class 150 and Class 300

Applicable temperature: -29℃-425℃

Applicable media: water, steam, oils, seawater, corrosive medias, etc.

Body material: WCB, CF8, CF8M, CF3, CF3M.

Operating method: manual, hand wheel(worm gear box), electric actuator, pneumatic actuator, hydraulic actuator.

How lugged high performance butterfly valve works:

API 609 lug style high performance butterfly valve is actually one special butterfly valve, which have one disc-like plate rotating around the valve shaft to realize the opening and closing of the butterfly valve. API 609 HP lugged butterfly valve is mainly used to cut off and throttle in the pipeline system.

Types of API 609 high performance butterfly valves:

with different end connect, API 609 high performance butterfly valves can be divided into wafer high performance butterfly valves, lug style high performance butterfly valves and flanged type high performance butterfly valves.

for different material used as body material, HP butterfly valves can be divided into WCB/carbon steel high performance butterfly valves, stainless steel CF3/CF3M/CF8/CF8M high performance butterfly valves.

according to different pressure rate, there are Class 150 API609 high performance butterfly valves, Class 300 API609 high performance butterfly valves, Class 600 API 609 high performance butterfly valves.

Main advantages of API HP butterfly valve lugged:

1. This API 609 high performance lugged butterfly valve has reasonable design, compact structure, is easy for assembly and disassembly, and convenient for maintenance.

2. this API HP butterfly valve lugged style adopts the double eccentric structure design to reduce the friction of the sealing ring and extend to the service life of the valve.

3. this double eccentric API 609 high performance butterfly valve can realize zero sealing effect, it can be used in high temperature, high pressure even ultra-high vacuum working conditions.

4. the material of the valve body, valve plate, valve shaft, sealing part in API high performance butterfly valve are optional, to be applicable for different medias and different pressure and temperature.

Applications of API double offset high performance butterfly valves:

High performance butterfly valve, also called double eccentric/double offset high performance butterfly valve, is mainly used for drainage in water plants, power station, steel plant smelting, chemical industry, water source engineering, environmental facility construction and other systems, especially for water pipelines, as the adjustment and sealing control equipment. Compared with the centerline butterfly valve(the concentric butterfly valve some people called), that dual eccentric high performance butterfly valve is more resistant to high pressure, and high temperature working conditions, and has a longer service life and better stability.

Standard applied for API 609 high performance butterfly valve:

| Design and Manufacturing | Flange | Inspection and Test | Temperature and Pressure standard |

| API 609 | ASME B16.5 | API 598 | ASME B16.34 |

Material options for main components in API HP butterfly valve:

| Component name | Material options |

| Valve body | WCB/CF8/CF8M/CF3/CF3M/Monel/Hastelloy Alloy |

| Valve disc | CF8/CF8M/CF3/CF3M |

| Valve stem | 17-4PH/304/316/1CR13/2CR13 |

| Valve seat | PTFE/RPTFE/PPL |

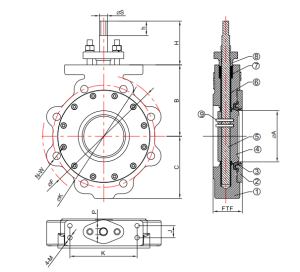

Class 150 Lugged type high performance butterfly valve dimension

| NPS | φA | B | C | FTF±3.3 | H | h | P | φS | J | K | M | φF | φK | N-W |

| 2.5″ | 59 | 111.1 | 82.5 | 48 | 82 | 27 | 11.2 | 14.8 | 125.4 | 22.4 | M10 | 180 | 139.7 | 4-5/8″-11UNC |

| 3″ | 73 | 120.5 | 93 | 48 | 82 | 27 | 11.2 | 14.8 | 125.4 | 22.4 | M10 | 190 | 152.4 | 4-5/8″-11UNC |

| 4″ | 96 | 133.3 | 110 | 54 | 82 | 27 | 11.2 | 14.8 | 125.4 | 22.4 | M10 | 230 | 190.5 | 8-5/8″-11UNC |

| 5″ | 111 | 135 | 120 | 57 | 82 | 27 | 11.2 | 14.8 | 125.4 | 22.4 | M10 | 255 | 215.9 | 8-3/4″-10UNC |

| 6″ | 142 | 152.4 | 135 | 57 | 82 | 27 | 14 | 18 | 125.4 | 22.4 | M10 | 280 | 241.3 | 8-3/4″-10UNC |

| 8″ | 188 | 187.3 | 172 | 64 | 82 | 27 | 15.9 | 21.9 | 125.4 | 22.4 | M10 | 345 | 298.5 | 8-3/4″-10UNC |

| 10″ | 236 | 231.8 | 202 | 71 | 97 | 28 | 20.6 | 28 | 142.7 | 37.3 | M12 | 405 | 362 | 12-7/8″-9UNC |

| 12″ | 282 | 260.3 | 241.3 | 81 | 97 | 33 | 23.8 | 33.3 | 142.7 | 37.3 | M12 | 485 | 431.8 | 12-7/8″-9UNC |

| 14″ | 314 | 315 | 295 | 92 | 105 | 41 | 28.7 | 37 | 142.7 | 37.3 | M16 | 535 | 476.3 | 12-1″-8UNC |

| DN | NPS 2.5"-24" |

|---|---|

| PN | class 150 and class 300 |

| standard | API 609 |

| Applicable temperature | -29℃-425℃ |