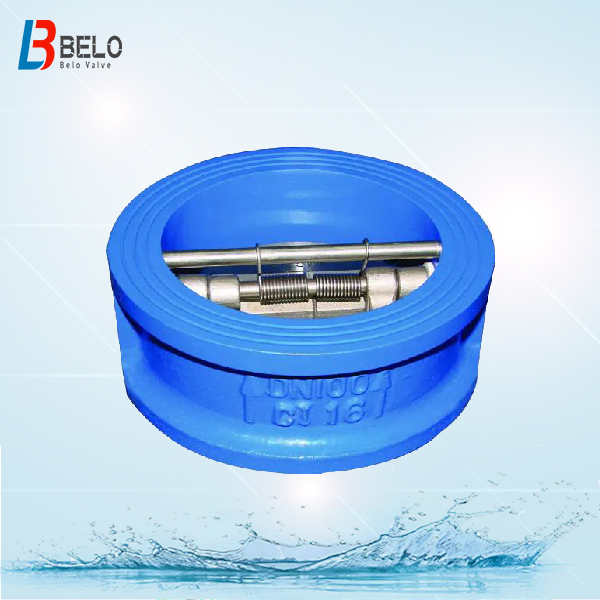

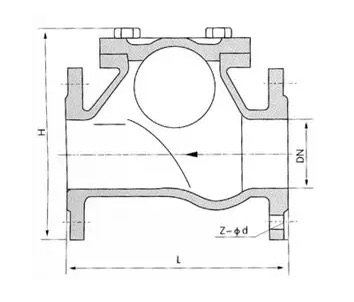

Check valve is one kind of industrial valves whose opening and closing part is a circular disc, and works by its own weight and medium pressure to prevent the back flow of the mediums. It is one kind of automatic valve, also called cut off valve, non return valve, one way valve, return valve, isolating valve. The check valve is widely used as the bottom valve(foot valve) of the water pump devices, which can prevent the water from flowing back. If the check valve is working together with the globe valve, which can realize safety isolation. The disadvantage of check valve is that the resistance is large, and the sealing performance is poor when the check valve is close.

The check valve consists of wafer butterfly check valves, rubber disc check valves, swing check valves, and ball type check valves, with different valve body materials used, the check valve has stainless steel check valve, cast iron(ductile cast iron) check valve, carbon steel check valve, forge steel check valve, and brass check valve.

The ball type check valve is one of the best check valves used in sewage and drainage systems.

Ball type check valve is mainly composed of valve body, rubber ball, valve bonnet,etc. The rubber ball rolls in the valve body for a short stroke to realize the opening and closing of the check valve. When the water pump starts working, the rubber ball is moved to rise up to the bonnet by the water pressure, then the ball type check is open; when the water pump stop working, due to the return water pressure in the pipeline system, the rubber ball is forced to roll back to the left front valve body, then the check valve is closed.

The rubber ball is made of hollow steel ball with good elasticity rubber attached outside. It not only ensures the sealing effect, but also reduces the damage to the pipeline system caused during the valve closing. When the check valve is working, that rubber ball will continuously roll over the sealing surface with the water flow, which has a cleaning effect on the sealing surface. If there is any foreign matters stuck on the sealing surface, the rolling rubber ball will remove them at the first time to ensure the effective sealing. In addition, that rubber ball is evenly stressed when the check valve is working, it has a solid structure, and it is less likely to be damage.