Gate valves and check valves are both widely used industrial valves. while definitely, gate valve and check valve are two different type valves, they have different structure design, different function in the pipe systems. today we are going to introduce the difference between check valve and gate valve in design, function, flow capacity, operating, applications.

1. For gate valve:

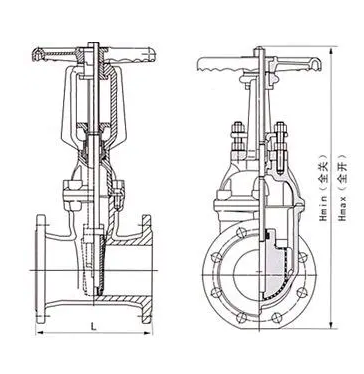

Gate valve refers to a valve whose closing part moves in the vertical direction of the channel axis. It is mainly used to cut off the medium on the pipeline, that is, the gate valve is fully opened or fully closed.

In general, gate valve cannot be used to regulate flow. With different material used for the gate valve, it can be applied to low temperature,low pressure pipelines and also can be applied to high temperature and high pressure pipelines.

1.1. the advantages of gate valve:

①. the gate valve has small flow resistance.

②. the gate valve requires less torque for opening and closing.

③. the gate valve can be used on the ring network pipeline where the medium flows in two directions, that is to say, the flow direction of the medium is not restricted.

④. when the gate valve is fully open, the sealing surface is less eroded by the working medium than the globe valve.

⑤. the gate valve has relatively simple body structure, and its manufacturing process is better.

⑥. the face to face length of the gate valve is relatively short.

1.2. the disadvantage of gate valve

①. the gate valve’s external dimensions and opening height are large, so it requires larger space to install.

②. During the gate valve’s opening and closing process, the sealing surface is relatively rubbed, and the friction loss is large, and even when the temperature is high, it is easy to cause scratches.

③. Generally, the gate valves have two sealing surfaces, which makes it difficult to process, grind, and maintain.

④. the gate valve has longer opening and closing time.

2. For check valve:

The check valve is also called cut off valve, one way valve, back-pressure valve, non-return valve. These check valves are automatically opened and closed by force generated by the flow of the medium itself in the pipelines, and they are one kind of automatic valve.

2.1. Where the check valve is used:

The check valve is mainly used in the pipeline system, and its main function is to prevent the backflow of the medium, the reverse rotation of the pump and the driving motor, and the discharge of the medium in the container. The check valve may also be used on auxiliary supplying pipe lines system where the pressure may rise above the system pressure.

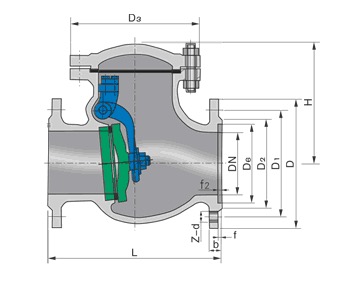

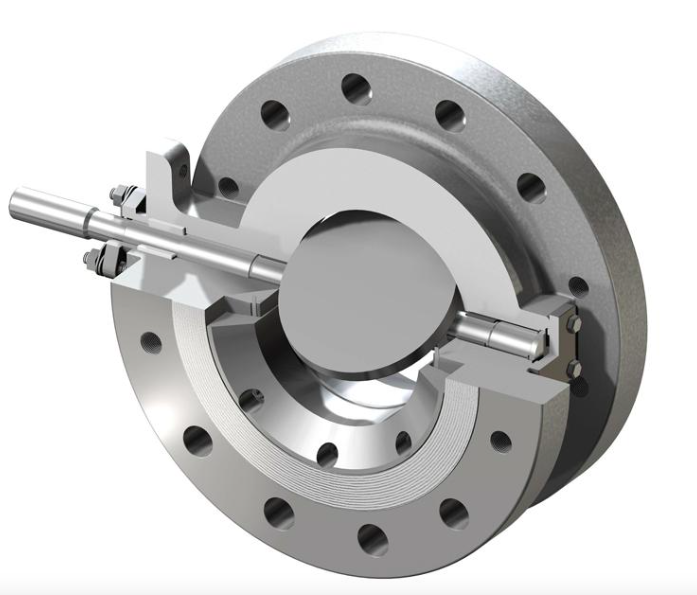

The check valve mainly includes swing check valve( rotating around the center of the gravity), lift check valve(move along the axis line), wafer butterfly type check valve, ball type check valve, shuttle check valve.

3. Check valves VS Gate valves:

after introducing gate valve and check valve separate, we are going to introduce the main differences between check valves and gate valve in design, function, flow capacity, operating and applications.

3.1.check valves and gate valves have different structure design:

Gate valves have a gate or wedge-shaped disc that moves up and down to control the flow of the media. They often have a rising stem that indicates the position of the gate. Check valves have different designs, such as swing check valves, lift check valves, or rubber ball check valves, rubber disc check valve, etc. These designs of check valves allow for different mechanisms to prevent back flow, such as a swinging disc, a lift disc, or a rubber ball that moves out of the way when fluid flows in the desired direction.

3.2. gate valves and check valves have different function in pipelines:

gate valves have one plate which moves up and down perpendicular to the direction of the fluid flow to open and cut off the media flow. gate valves can only be opened and closed fully, cannot be used for regulating. while check valves have total different function compared with those gate valves, check valves are one kind of automatic valve, like the swing type check valve, which has one swing disc handing on the valve body, that disc will be opened by the flow pressure when the media flows through the check valve, and when the pressure is going down, that disc will close by its gravity and make the check valve closed to prevent the back flow of the media.

3.3. check valves and gate valves have different flow capacity:

Gate valves typically have a higher flow capacity compared to check valves. Gate valves provide a straight-through flow path when fully opened, allowing for unrestricted flow. Check valves, however, have a smaller flow capacity due to their design that includes a disc, flap, or rubber ball that blocks flow in the reverse direction.

3.4. check valves and gate valves have different operating method:

gate valves can be operated by manual hand wheel or through an actuator (bevel gear, electrical actuator, pneumatic actuators, etc). in short, the external force is used to move the disc up and down to realize the opening and closing of the gate valves. however, check valves operate automatically, relying on the pressure difference across the check valve to open or close. They do not require external control or actuation.

3.5. gate valves and check valves have different industrial applications:

Gate valves are commonly used in applications where a straight-through flow path, high flow capacity, and tight shut-off are required, such as in oil and gas pipelines, water treatment plants, and chemical processing. while different from gate valves, check valves are used in applications where back-flow prevention is critical, such as in plumbing systems, wastewater treatment, and pumping stations.

After this blog, believe you already have some simple understanding about those differences between check valves and gate valves, while for a proper valve selection, thats not enough, in order to choose a right industrial valve, we also should know our real working conditions, like the real working pressure, temperature, media, flow rate, acid-base property of the media, installation place and space, etc. if you still have no idea how to decide which valves should be used, you can contact our sales direct, a professional advice can be offered.

By the way, Belo Valve is one professional wholesale supplier, exporter for resilient seated and metal seated hard sealing gate valves and check valve series like BS/DIN swing check valves, rubber ball check valves, rubber disc check valves, wafer dual disc check valves, foot valves, etc.