The disc of the swing check valve rotates around the axis. Its fluid resistance is generally smaller than that of the life type check valve, and it is suitable for pipelines with larger diameters. According to the quantity of disc, swing check valve can be divided into single disc swing check valve, double disc swing check valve, multi disc swing check valve. Single disc swing check valve is generally suitable for medium diameter pipelines. When the single disc swing check valve is used in large diameter pipeline, in order to reduce the water hammering, the slow closing check valve will be used. Dual disc swing check valve is suitable for large and medium pipelines. Wafer dual disc swing check valve has small size and light weight, is one fast developed check valve. Multi-disc swing check valve is used for large diameter pipelines.

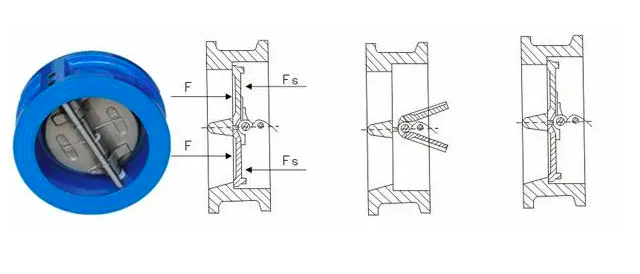

The structure of the wafer type check valve is similar like the butterfly valve. Its structure is simple, flow resistance is small, and also water hammering pressure is small.

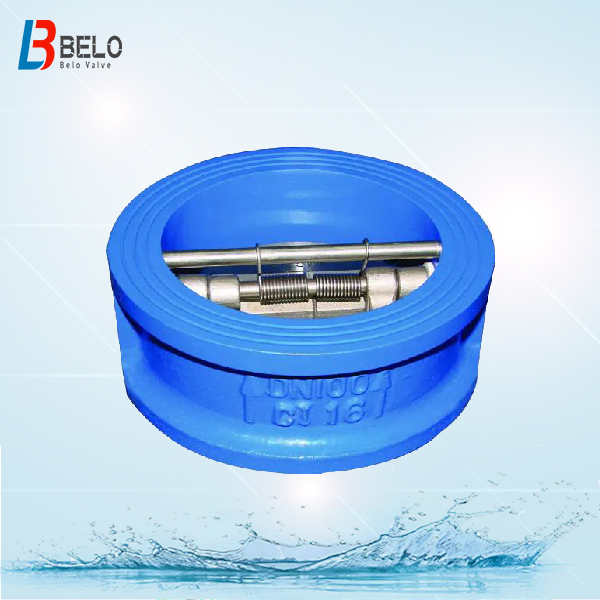

1. What is wafer type check valve?

The inside of the wafer check valve is composed of two semi-circular springs and a plate surface. The spring is fixed on the valve body with a pin to close the valve plate, and the fluid pressure forces the spring to open quickly, which can protect the pipeline from be damaged by water hammering. Wafer butterfly check valve is suitable for various pipelines with nominal pressure PN1.0MPa~42.0MPa ,Class150~2500; nominal diameter DN12~1200mm、NPS1/2~48;working temperature -196~540℃; it is installed to prevent the backflow of mediums. For different material used for wafer check valve, it can applied to various mediums such as water, stream, oils, nitric acid, acetic acid, strong oxidizing medium and urea.

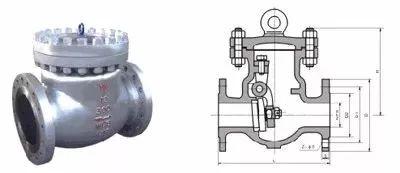

2. what is swing check valve ?

The swing check valve is one kind of check valve in which the valve plate rotates around the rocker shaft in the body cavity. The opening and closing principle of the swing check valve is same as that of the lift check valve. It also depends on the action of fluid pressure and self-weight of the disc to open and close. The different is that the movement of the disc is rotational not up-and-down. The inlet direction of the swing check valve should be on the side which can impact the rotation of the disc.

Due to the weight of the disc, when the swing check valve is open, the resistance to the fluid is relatively large. In addition, because the valve plate is suspended in the fluid, the fluid can be turbulent. This also shows that the flow drop across the swing check valve is larger than that across other types of check valves. When the flow direction changes suddenly, the valve disc will be violently closed on the valve seat, which will cause great wear on the valve seat and produce water hammering along the pipeline. To overcome this problem, a damping device can be installed on the valve disc, and the metal seat can be used to reduce wear.

3. The difference between wafer check valve and swing check valve:

3.1. In water hammering pressure:

For wafer check valve: small water hammering pressure, short closing stroke, quick closing.

For swing check valve: large water hammering pressure, long closing stroke, long closing time.

The water hammering pressure of wafer check valve is only 1/2~1/5 of the swing check valve.

3.2. In size and weight:

For wafer check valve: short face to face length, small size, light weight, convenient to install, delivery, store, material saving and low cost.

For swing check valve: the face to face length is long, bulky in size, and heavy.

The face to face length of wafer check valve is 1/4~1/6 of swing check valve, the weight of wafer check valve is 1/4~1/10 of swing check valve.

3.3. In flow resistance:

For wafer check valve: its flow resistance is small, its flow resistance coefficient is ξ=2.6~2.7, with the diameter become larger, its flow resistance coefficient becomes smaller.

For swing check valve: its flow resistance is small, its flow resistance coefficient is ξ=1.3~3. but when the pressure is low, the disc couldn’t open fully, the flow resistance will be large, the flow resistance coefficient will be larger when the diameter becomes larger.

3.4. In installation:

The wafer check valve can be installed vertically and horizontally, its weight is light, no need to install the support platform.

The swing check valve can be installed vertically and horizontally, when the diameter becomes larger, its weight will become heavy, it needs a support platform.

3.5. In opening pressure:

The wafer check valve can be opened fully with small pressure difference.

The swing check valve can be only opened with a large pressure difference.

3.6. In reliability:

The wafer check valve is an integral structure, it is simple and compact, the impact force is small when the valve is closed, the water hammering is small, its service life is long, and has high reliability.

For swing check valve, the huge impact force and water hammering pressure generated when the valve is closed can easily damage the valve.

For more information about check valve, kindly visit our other articles:

- What is the difference between lift check valve and swing check valve?

- What are the 5 types of check valves?

- How to inspect a check valve?

- What is a lift check valve(lift disc check valve)?

- What is wafer type check valve(also called butterfly type check valve)?

- What is ball type check valve?

- What is the difference between gate valve and check valve?

- How does a check valve work on sump pump?

- Where to install check valve on water pump?

- How to repair a failed check valve?

- where should a check valve be installed in piping systems

- How do you stop water hammering?

- Can swing check valve be installed vertically? or only horizontally?

- What is a wafer butterfly check valve?