The check valve is one kind of accessory widely installed in various industrial pipeline systems. It has three main functions, preventing the back-flow of the medium, preventing the reverse rotation of the water pump and the driving motor, and discharging the container medium.

The check valve is suitable for various industrial pipelines, water supply and drainage systems, domestic water pipe network and other industrial fields. As one kind of commonly used valve, the check valve has the advantage of preventing pollution and safety concerns caused by the back-flow of the medium, but its disadvantage is that the check valve will cause a certain energy loss.

1. Why check valves are installed in pipe systems?

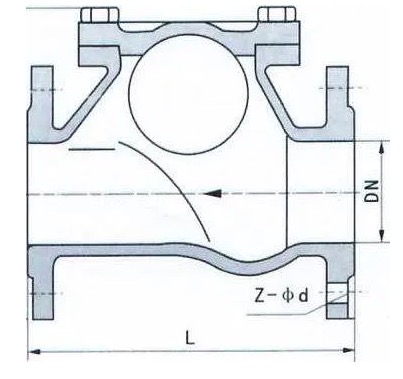

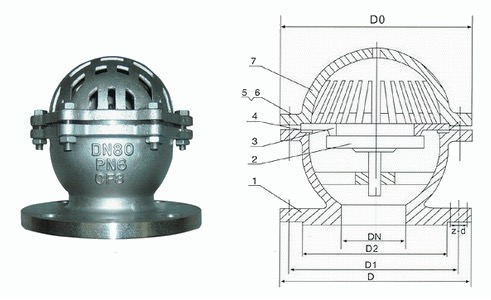

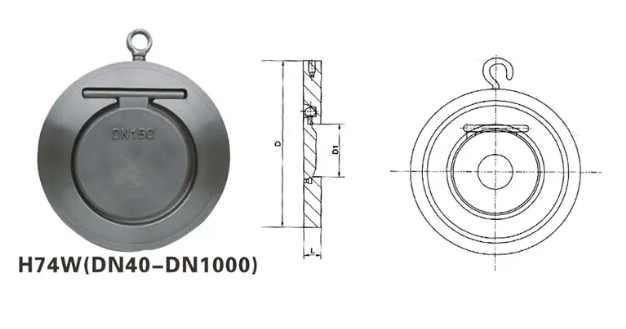

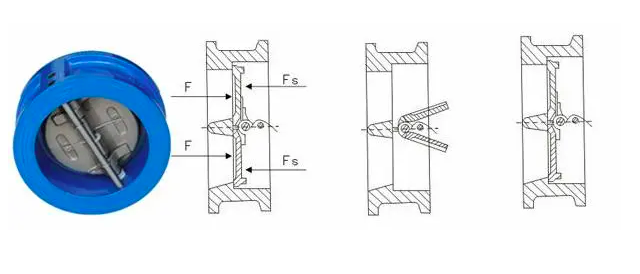

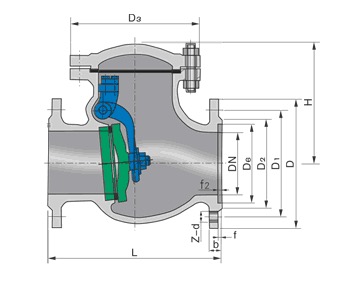

Check valve ,also known as non return valve, back pressure valve, one way valve, is one kind of industrial valve which is widely installed in pipe line systems to prevent the mediums from flowing back. Check valve can be divided into wafer type check valve, lift type check valve, wafer butterfly type check valve, line check valve, compression check valve. There are plenty reason why the check valves are installed, here are some mainly one:

1.1. to prevent the back-flow of the medium.

To prevent the back-flow of the medium is the main function of check valve. The check valve has only one flow direction, so the medium passing through the check valve can only flow along the direction of the inlet, the medium couldn’t flow back from the opposite direction. When the medium flows back, the check valve will close, thereby to prevent the medium from flowing back.

1.2. to prevent the water pump and driving motor from reversing.

The check valve can be applied to the sump pump and driving motor to prevent the pump and driving motor from reversing by cutting off the reverse flow of the medium.

1.3. to discharge the container mediums.

The medium inside the container can be discharged through the check valve, and the medium discharged can be prevented from flowing back into the container.