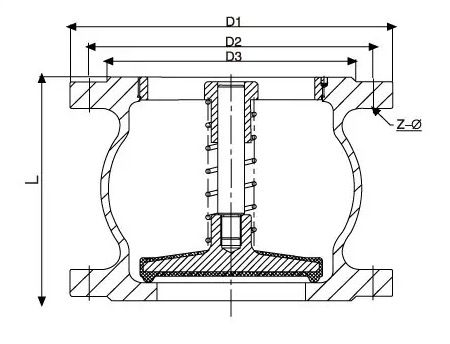

The silent check valve is a check valve which can reduce or eliminate the noise generated by the water flow through the valve. The reason why the silent check valve has the silencing effect is that the internal water flow path of the silencing check valve adopts a streamlined design, and the head loss is extremely small. And the disc of the silent check valve can be quickly closed to avoid water hammer and prevent huge water hammer sound, so as to have the effect of noise reduction.

How the silencing check valve works?

The check valve can prevent the back-flow of the internal medium, but it has a disadvantage, that is, the check valve will generate relatively large noise. In some special occasions, lower noise is required, that is why the silencing check valve is designed. Then let’s talk about how the silent check valve works.

Ordinary check valve will generate when they are working, that is because the water pressure and flow are affected when the water is passing through, and there will be some certain amount of energy loss. These energy losses will generate water hammering and cause noise. While the internal water flow path of the silencing check valve adopts streamline design, its water head loss is extremely small, which is almost 1/2-1/3 of that of ordinary check valve; at the same time, since the disc of the silencing check valve is spring loaded, the closing stroke of the disc is very short when the pump is closing, the check valve can close quickly, which can avoid water hammer and prevent the huge noise from the water hammering. Therefore it can have the effect of silencing.

The silent check valve is one kind of hydraulic industrial valve, which is installed in outlet of the sump pump, to avoid the water hammering, prevent the back-flow of the medium, and reduce the noise generated when the check valve is working.