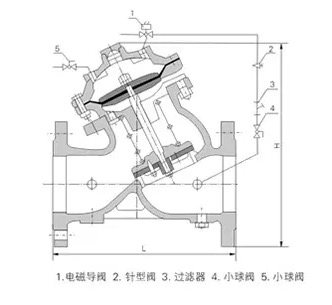

Multi-function check valve(or multi-function pump control valve) refers to the valve which automatically opens and closes the valve plate depending on the flow force of the medium itself to prevent the back-flow of the medium. The multi function check valve is also known as one way valve, non return valve, cut off valve, back pressure valve. The principle of multi-function check valve is that when the medium flows back, the valve disc is closed to the sealing surface of the valve seat, due to the self-weight of the valve disc and the action of her reverse force of the medium.

1. How the multi-function check valve works?

When the medium flows in the specific direction, the valve disc is opened by the force of the medium; when the medium flows backward, the valve disc and the sealing surface of the valve seat are tightly closed due to the self-weight of the valve disc and the action of the reverse force of the medium to prevent the reverse flow of the medium.

2. How to install multi function check valve?

2.1. Before the installing the multi function check valve, it is necessary to clean the check valve to prevent the valve from being stuck, and to reduce fluid loss during the delivering of the medium.

2.2. when installing the multi function check valve, the model no and specifications of the check valve must be inspected in detail and they must meet the requirements of the equipment.

2.3. the lift multi-function check valve should be installed in vertical pipe lines, which can enhance the advantage of downstream.

2.4. the lift horizontal multi function check valve can be only installed in horizontal pipe lines.

2.5. when installing the multi-function check valve, it is necessary to determine the flow direction of the fluid medium, and then keep the multi function check valve consistent with the normal flow direction of the medium. The purpose of keeping the valve body of the multi function check valve consistent with the fluid direction is to avoid cutting off the normal flow of the medium.

2.6. when the multi function check valve is closed, the pipeline will generate a large water hammer pressure, so the multi function check valve is better to be installed in horizontal pipe lines, which can reduce the damage to the valve. Especially in the case of some large scale fluid medium pipelines.