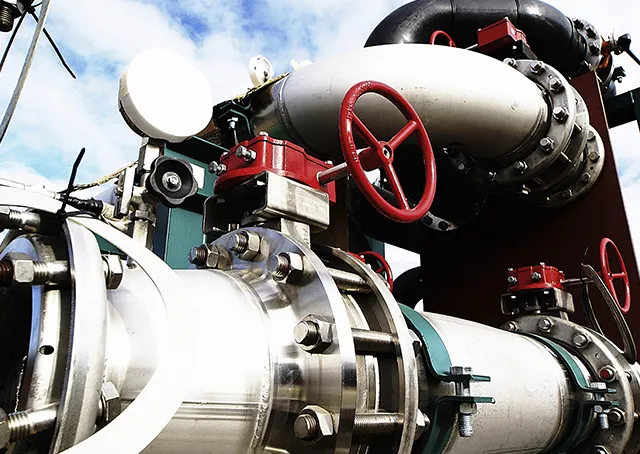

The check valve is one kind of accessory widely installed in various industrial pipeline systems. It has three main functions, preventing the back-flow of the medium, preventing the reverse rotation of the water pump and the driving motor, and discharging the container medium. Check valve can be divided into wafer type check valve, lift type check valve, wafer butterfly type check valve, line check valve, compression check valve.

The check valve is suitable for various industrial pipelines, water supply and drainage systems, domestic water pipe network and other industrial fields. As one kind of commonly used valve, the check valve has the advantage of preventing pollution and safety concerns caused by the back-flow of the medium, but its disadvantage is that the check valve will cause a certain energy loss.

1. Where are the check valve used?

There are many types of check valves, different types of check valves can be used in different places, mainly check valves are installed in following pipe line systems:

1.1. check valve is used in water supply networks in high rise buildings.

1.2. Check valve can be used in pipe line networks with certain chemically corrosive mediums.

1.3. Check valve can be installed in sewage networks.

1.4. Check valve is used in water supply and drainage system.

1.5. Check valve can be used in underwater diving, drainage, sewage pumps.

1.6. Check valve is widely used in domestic water pipe networks.

1.7. Check valves can be used in pipeline systems in petroleum, chemical, metallurgical and other industrial sectors.