Check valve, widely also known as one way valve, one way water valve, non return valve, back water valve, back pressure valve, cut off valve, non return check valve,etc, is one kind of automatic industrial valve, which is used in industrial pipelines to prevent the back flow of the medium,like in water supply and drainage system, at the bottom of the water pump, etc. With different material used for check valve body, like cast iron, cast steel, forged steel, stainless steel, brass, the check valve can be used for various mediums, like water, steam, oils, natural gas,etc.

Although the purpose of selecting a check valve for a compressible fluid line is to minimize the impact of the valve disc, the check valve can be selected according to the similar selection method for a check valve for in-compressible fluids. However, for very large diameter pipelines, the impact of the compressible mediums can also become considerable;

If the flow of the medium fluctuates widely, the check valve for compressible liquids can use a reduction device. This reduction device operates throughout the whole movement of the check valve, to prevent rapid succession of hammer blows to its end.

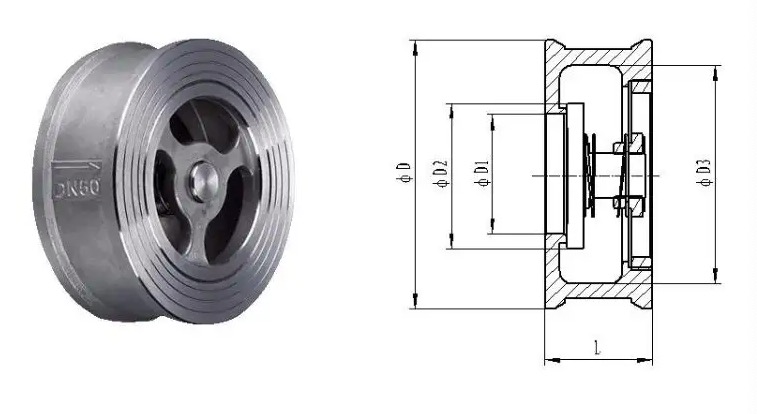

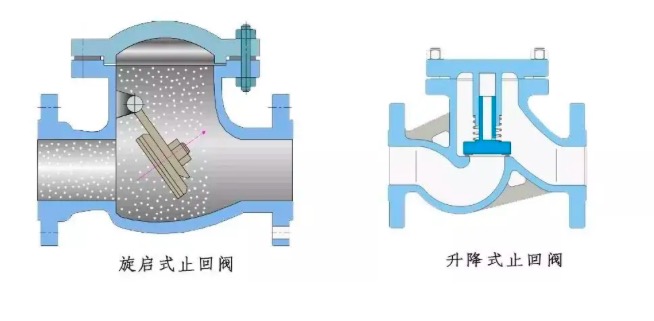

A lift check valve should be used if the medium flow is stopped and started quickly and continuously, like at the outlet of a compressor. Lifting type check valve uses a lightweight spring-loaded disc that does not have a high lifting distance.

Purchase guideline for what kind of check valve should be used in your pipelines:

1. In order to prevent the back flow of mediums, the check valves should be installed on equipment, assembly lines and pipelines;

2. Check valves are generally suitable for clean mediums, not for mediums containing rigid particles and high viscosity;

3. Generally, vertical lift check valve should be used on pipelines with a nominal diameter of 50mm;

4. Straight through lifting type check valve can be installed on both horizontal and vertical pipelines;

5. For the water pump inlet pipeline, the bottom valve(foot valve) should be selected. The bottom valve(foot valve) is generally only installed on the vertical pipeline of the water pump inlet, and the medium flows from bottom to top;

6. The lifting type check valve has better sealing performance than the swing type check valve, its flow resistance is large. The horizontal type lift check valve should be installed on horizontal pipelines, and the vertical type lifting type check valve should be installed on the vertical pipelines;

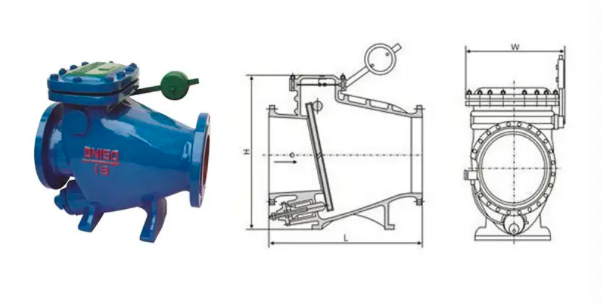

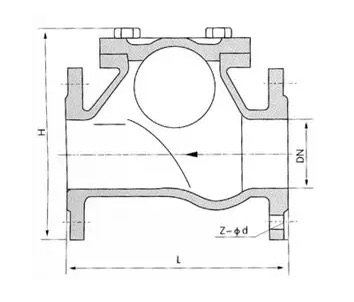

7. The installation position of the swing check valve is not limited. The swing check valve can be installed on horizontal, vertical or inclined pipelines. If the swing check valve is installed on vertical pipelines, the flow direction of the medium should be from the bottom to top;

8. The swing check valve should not be made into a small-diameter valve, and can be made into a very high working pressure valves. The PN(nominal pressure) of swing check valve can reach 42Mpa, and the DN(nominal diameter) of swing check valve can also be large, the maximum diameter of swing check valve can reach more than 2000mm. With different valve body material, and different sealing material for swing check valve, the swing check valve can be used for an medium and any working temperature. The applicable medium of swing check valve can be water, steam, gas, corrosive mediums, oils, medicine,etc. Its working temperature can range from -196–800℃;

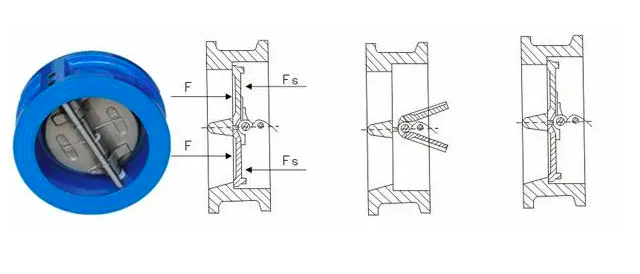

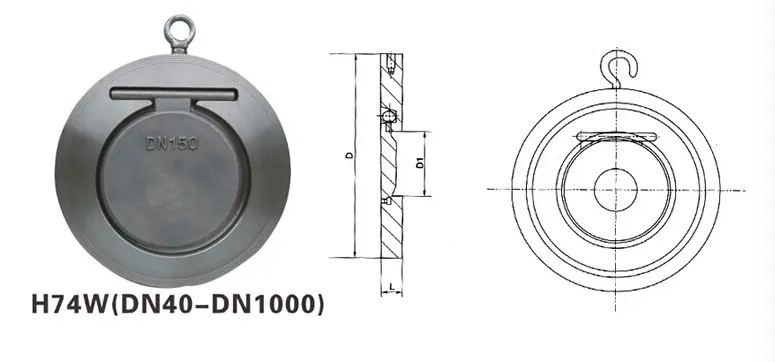

9. The installation position of the butterfly type check valve is not limited. Butterfly type check valve can be installed on horizontal pipelines or vertical or inclined pipelines;

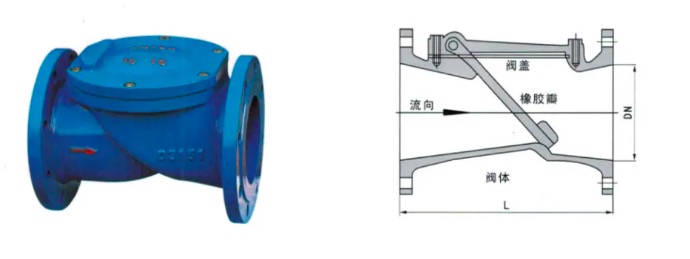

10. The diaphragm check valve is suitable for pipelines that are prone to generate water hammer. The diaphragm check valve can well eliminate the water hammer caused by the back flow of the medium. The diaphragm check valve is generally used in flow pressure and normal temperature pipelines, and is especially suitable for tap water pipelines. Generally, the working temperature of the medium in diaphragm check valve is between -12–120℃, its working pressure is <1.6MPa, but the diaphragm check valve can be made into a large diameter ones, its DN(nominal diameter) of diaphragm check valve can reach more than 2000mm;

11. Ball type check valve is suitable for medium and low pressure pipelines and can be made into large diameter ones;

12. The shell material of ball type check valve can be made of stainless steel, the follow sealing sphere can be wrapped with PTFE, so ball type check valve can be used in pipeline of general corrosive mediums, and the working temperature of ball type check valve is between -101–150℃, the nominal pressure of ball type check valve is ≤4.0MPa, the nominal diameter of ball type check valve is between 200—1200mm.

13. The corresponding size of the check valve should be determined. And the check valve supplier must supply the specifications data of the selected check valve, so that the check valve size can be found when the valve is fully open at a given flow rate;

14. For high and medium pressure check valve below DN50mm, the vertical lifting type check valve and straight through lift check valve should be used;

15. For low pressure check valve below DN50mm, butterfly type check valve, horizontal lift check valve and diaphragm check valve should be used;

16. For high and medium pressure check valve with DN greater than 50mm and less than 600mm, swing check valves should be used;

17. For medium and low pressure check valve with DN greater than 200mm and less than 1200mm, the non wear ball type check valve should be used;

18. For low pressure check valve with DN greater than 50mm, and less than 2000mm, the butterfly type check valve and diaphragm check valve should be used;

19. For pipelines with small or no water hammer when the check valve is closing, the slow closing type swing check valve and slow closing butterfly type check valve should be used;

With different working condition, different check valve should be selected, if you have no idea what kind of check valves, or what kind of industrial valves should be used in your projects, kindly contact us, we will give you professional advice.

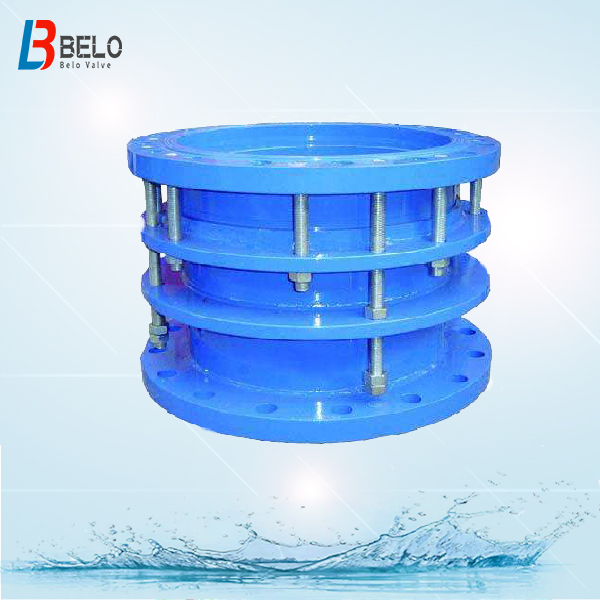

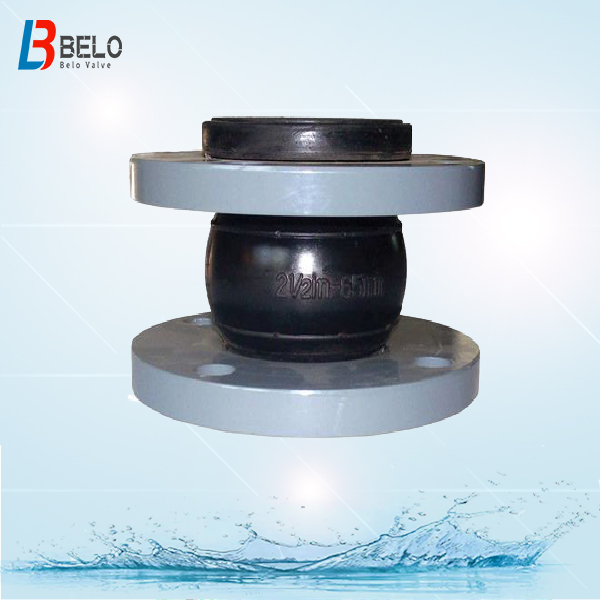

Apart from check valves, Belo Valve can also supply hard seal and soft seal gate valves, soft seal and hard seal butterfly valves, ball valves, globe valves, fire protection valves, hydraulic control valves, strainers, rubber and steel pipe joints.