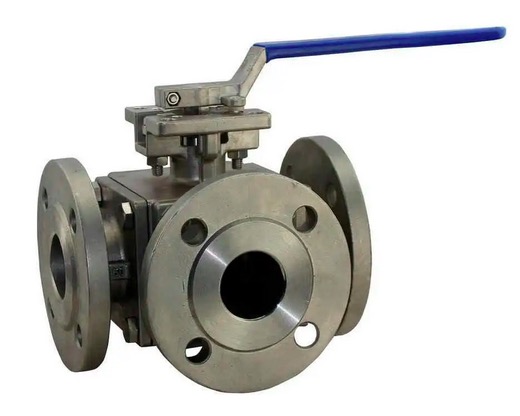

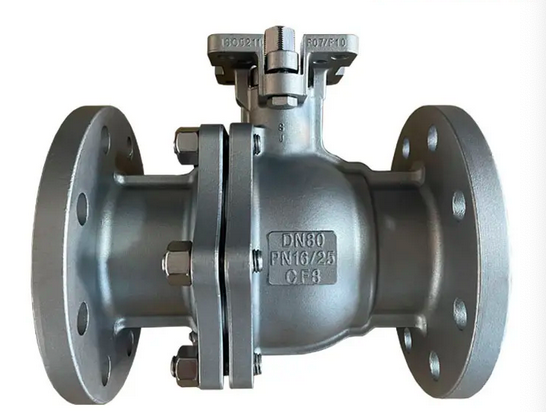

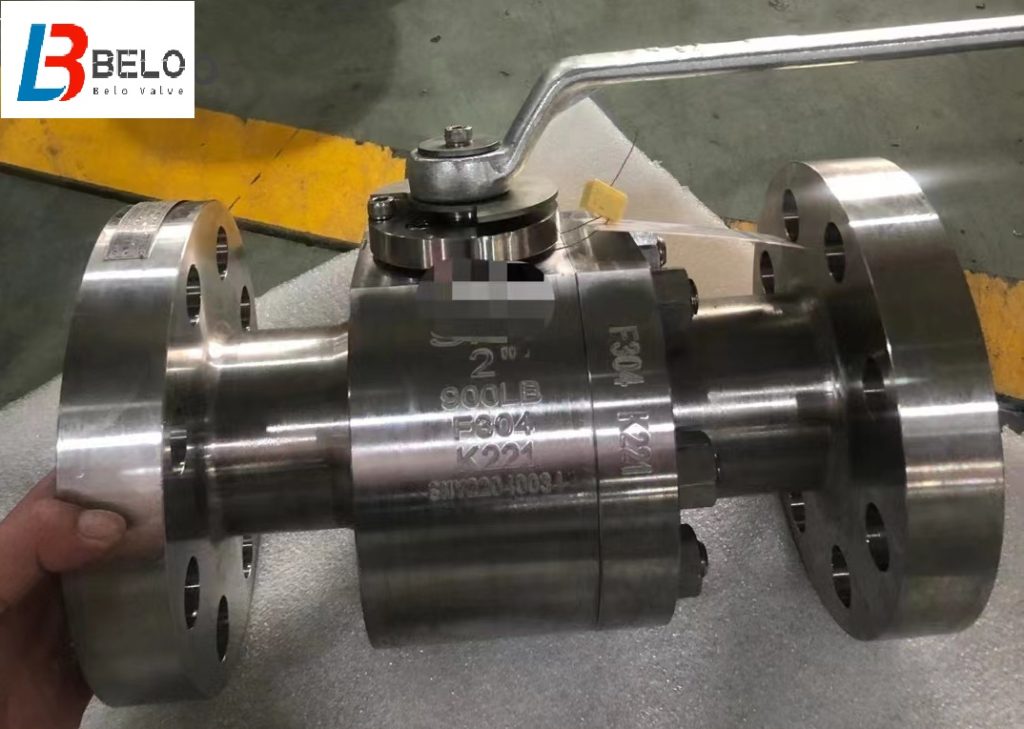

The ball valve evolved from the plug valve. Its opening and closing part is a ball, the ball valve uses the ball body to rotate 90° around the axis of the valve stem to open and close the ball valve. Ball valves are mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. Ball valves designed with a V-shaped opening also provide good flow regulation.

Advantages of ball valve:

① ball valve has the lowest flow resistance( actually the flow resistance of ball valve is 0).

②ball valve can be reliably used in aggressive medium and low-boiling liquids due to no sticking during operation( without lubricant);

③ball valve can be completely sealed over a wide pressure and temperature range;

④ball valve can achieve fast opening and closing, and the opening and closing time of some structures is only 0.05〜0.1s to ensure that the ball valve can be used in the automation system of the test bench. When the ball valve is opening and closing quickly, there is no vibration during operation;

⑤the spherical cap can be automatically positioned at the boundary position;

⑥ball valve has reliable sealing on both sides of the working medium;

⑦when the ball valve is fully opened and fully closed, the sealing surface of the ball body and valve seat are isolated from the medium, so the medium passing through the ball valve at high speed will not cause corrosion of the sealing surface;

⑧ball valve has compact structure, and light weight, ball valve can be considered as the most reasonable valve structure for low temperature medium system;

⑨the valve body of ball valve is symmetrical, especially the welded valve body construction can withstand the stress of the pipeline well;

⑩the closing part of the ball valve can withstand high pressure differentials. Ball valves with fully welded bodies can be buries directly in the ground, so the internal parts of the ball valve won’t be corroded, the maximum service life of ball valve can reach 30 years. Ball valve is the most ideal valve for oils and gas pipelines;

Disadvantages of ball valve:

①since the main seat sealing ring of the ball valve is made of PTFE, which is inert to almost all chemical substances, also has small friction coefficient, stable performance, not easy to age, a wide range of range of applicable temperatures, and excellent sealing performance. However, the physical properties of PTFE, including high coefficient of expansion, susceptibility to cold flow, and poor thermal conductivity, the design of valve seat sealing surface should consider those properties. Therefore, when the sealing material becomes hard, the reliability of the sealing is damaged. Also, PTFE has a lower anti-high-temperature rating, and can only be used at working temperature below 180℃. if the working temperature is over 180℃, the sealing material will deteriorate. If for a long time using, it usually is used at 120℃ Temperature.

②the regulation performance of ball valve is not as good as globe valve, especially for pneumatic valve( or electric valve);