Butterfly valve refers to a valve whose closing part(valve disc or butterfly plate) is a disc, which rotates around the valve shaft to achieve opening and closing. Butterfly valve is mainly used for cutting off and throttling on the pipelines. The opening and closing part of the butterfly valve is a disc-shaped butterfly plate, which rotates around its own axis in the valve body to achieve the purpose of opening and closing or adjustment. From fully open to fully closed, the rotating angle of the butterfly valve is usually less than 90°.

According to different sealing material used, butterfly valve is divided into soft sealing butterfly valve( also called resilient seated butterfly valve, soft seal butterfly valve), and metal hard sealing butterfly valve.

What is metal hard sealing butterfly valve:

A hard sealing butterfly valve refers to a butterfly valve whose sealing material pair are made of metal materials or other hard materials. This kind of metal hard sealing has poor sealing performance but has high temperature resistance, wear resistance and good mechanical properties. The hard sealing material pair can be: steel+steel; steel+copper; steel+graphite; steel+alloy steel; the steel material here mentioned can be cast iron, cast steel, alloy steel, or welded or sprayed alloy steel;

What is soft sealing butterfly valve:

Soft sealing butterfly valve refers to a butterfly valve where one side of the sealing pair is made of metal material, and the other side of the sealing pair is made of resilient non metallic material; this kind of resilient sealing has good sealing performance, but it is not resistant to high temperature, easy to wear, and has poor mechanical properties; the soft sealing material can be: steel+rubber; steel+NBR; steel+PTFE;

What is the difference between hard sealing butterfly valve and soft sealing butterfly valve:

The valve seat in soft sealing butterfly valve is made of non metallic materials with certain strength, hardness and temperature resistance. It has good sealing performance and can achieve zero leakage, but its service life and adaptability to temperature are relatively poor; the sealing material in hard sealing butterfly valve is made of metal, and its sealing performance is relatively poor, although some manufacturer claim that the hard sealing butterfly valves can achieve zero leakage;

The soft sealing butterfly valve can not meet the process requirements for some corrosive mediums, and the hard sealing butterfly valve can solve this problem. These two kind of seals can complement each other. In terms of sealing performance, soft sealing butterfly valves are relatively good, but now the sealing performance of hard sealing butterfly valve can also meet the corresponding requirements;

The advantage of soft sealing butterfly valve is good sealing performance, but the disadvantages of soft sealing butterfly valve is easy aging, wear and short service life. The hard sealing butterfly valve has a long service life, but the sealing performance of hard sealing butterfly valve is relatively poorer than that of the soft sealing butterfly valve;

Structural differences between hard sealing butterfly valve and soft sealing butterfly valve:

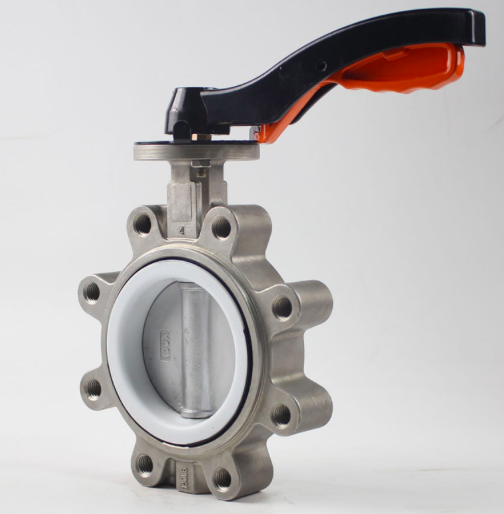

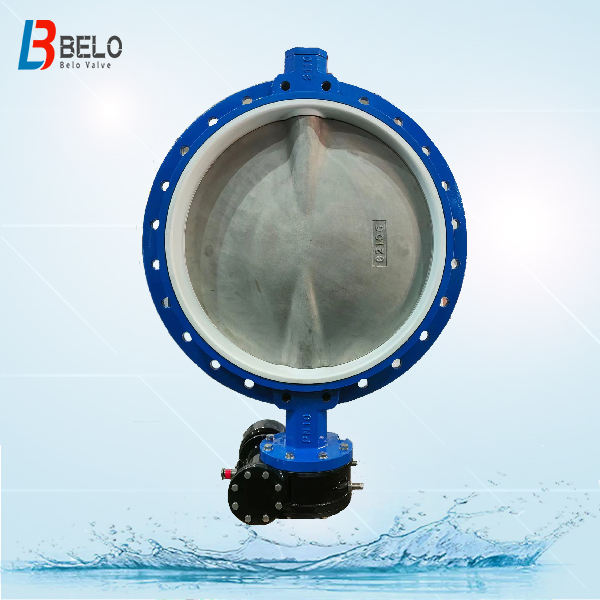

① structural difference:the soft sealing butterfly valves are mostly center line butterfly valves( or called concentric butterfly valves); while the hard sealing butterfly valves are mostly eccentric butterfly valves, like single eccentric butterfly valves, double eccentric butterfly valves and triple eccentric butterfly valves;

② difference in temperature resistance: soft sealing butterfly valves are used in normal temperature environments. While hard sealing butterfly valves can be used in low temperature, normal temperature, high temperature and other environments;

③ difference in working pressure: soft sealing butterfly valve are used for low pressure and normal pressure conditions; while hard sealing butterfly valves can also be used in medium and high pressure conditions;

④ difference in sealing performance: soft sealing butterfly valves and triple eccentric hard sealing butterfly valves have better sealing performance, and triple eccentric butterfly valves can maintain good sealing performance under high temperature and high pressure;

In view of the above characteristics, soft sealing butterfly valve is suitable for bidirectional opening, closing and adjustment of ventilation and dust removal pipelines, water treatment, light industry, petroleum, chemical and other industries; while hard sealing butterfly valves are mostly used in heating, gas supply, gas, oil, acid and alkali environments;

With the widely applications of butterfly valves, the characteristics of convenient installation, convenient maintenance and simple structure are becoming more and more obvious;

Electric soft sealing butterfly valve, pneumatic soft sealing butterfly valve, hard sealing butterfly valve,etc are beginning to replace electric gate valves, globe valves,etc in more and more occasions.

For more technical parameters or prices about soft sealing butterfly valves or hard sealing butterfly valves, kindly contact us:

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves, forged ball valve, two piece forged ball valves, three piece forged ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.