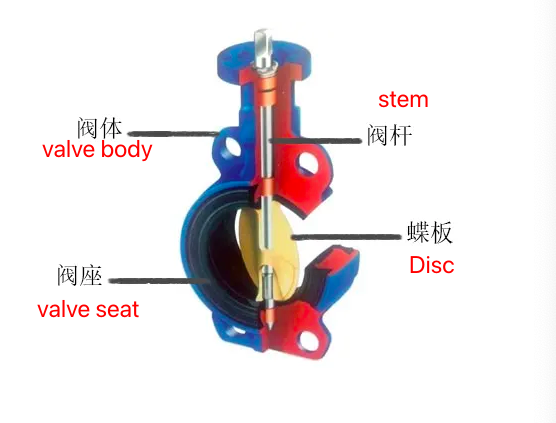

Butterfly valve refers to a valve whose closing part(valve disc or butterfly plate) is a disc, which rotates around the valve shaft to achieve opening and closing. Butterfly valve is mainly used for cutting off and throttling on the pipelines. The opening and closing part of the butterfly valve is a disc-shaped butterfly plate, which rotates around its own axis in the valve body to achieve the purpose of opening and closing or adjustment. From fully open to fully closed, the rotating angle of the butterfly valve is usually less than 90°.

The butterfly valve and the valve stem have no self-locking ability. In order to locate the butterfly plate, a worm gear reducer should be installed on the valve stem. The use of worm gear reducer can not only make the butterfly plate have self-locking ability, so that the butterfly plate can stop at any position, but also improve the operation performance of the butterfly valve;

According to different body material, butterfly valve can be divided into cast iron butterfly valve, cast steel butterfly valve, and stainless steel butterfly valve; today we are gonna talk about the differences between cast iron butterfly valves and cast steel butterfly valve:

What is cast iron butterfly valve?

Cast iron butterfly valve, also know as cast iron flap valve, gray cast iron butterfly valve, ductile cast iron butterfly valve, ductile iron butterfly valve, is one kind of regulating valve with simple structure, and can also be used for on-off control of medium in low pressure pipelines.

Cast iron butterfly valve is one kind of butterfly valve, whose main parts material is made of cast iron, like valve body, stem or disc;

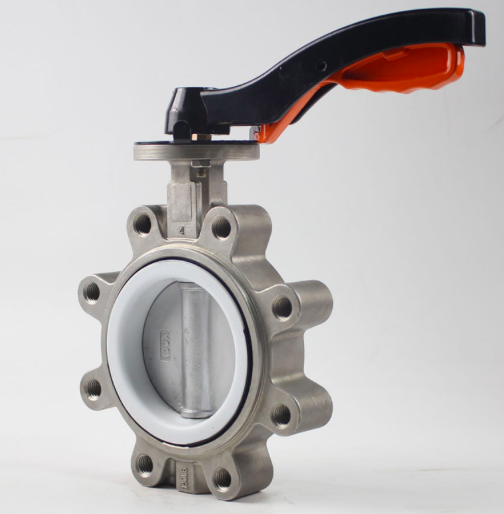

According to end connections, cast iron butterfly valve can be divided into wafer type butterfly valve, wafer lug type butterfly valve and flange type butterfly valve. The wafer type butterfly valve is connected between the two pipeline flanges with studs. The flange type cast iron butterfly valve has flanges on the valve body, and those flanges at both ends of the butterfly valve are connected to the pipeline flanges with bolts;

According to different operating methods, there are manual cast iron butterfly valve, electrical cast iron butterfly valve, pneumatic cast iron butterfly valve. The cast iron butterfly valve is usually using soft sealing materials, like rubber, NBR, PTFE. So there are rubber lined cast iron butterfly valve, NBR lined cast iron butterfly valve, PTFE lined cast iron butterfly valve.

What is cast steel butterfly valve?

Cast steel butterfly valve, also known as carbon steel butterfly valve, carbon steel WCB butterfly valve,WCB steel butterfly valve,WCB butterfly valve, A216 WCB steel butterfly valve, is one kind of butterfly valve, whose valve body is mainly made of cast steel. The body material of cast steel butterfly valve is mainly divided into the following materials: cast steel, carbon steel, 20# steel, A182 steel, forged steel A105 F11 F22, chromium molybdenum steel WC6 WC9, stainless steel 304,316,etc;

The nominal diameter of cast steel butterfly valve can be DN15-DN1200, the nominal pressure of cast steel butterfly valve can be PN1.0-50Mpa. According to operating methods, there are manual lever cast steel butterfly valve, electrical cast steel butterfly valve, pneumatic cast steel butterfly valve, worm gear actuated cast steel butterfly valve;

The standard of cast steel butterfly valve can be: National Standard GB, American Standard API, ANSI, Japanese Standard JIS, German Standard DIN;

According to end connections, cast steel butterfly valve has wafer type cast steel butterfly valve and flange type cast steel butterfly valve;

Cast iron butterfly valve VS Cast steel butterfly valve

The cast iron butterfly valve refers to a butterfly valve whose body material is made of cast iron; cast steel butterfly valve refers to a butterfly valve whose body material is made of cast steel. So if we want to figure out the differences between cast iron butterfly valve and cast steel butterfly valve, we are actually try to figure out the differences between the cast iron material and cast steel material;

The main difference between cast iron butterfly valve and cast steel butterfly valve is the difference in carbon content, which directly affects the strength and plasticity of steel material;

Cast iron butterfly valve is more rigid and brittle than cast steel butterfly valve, and cast steel butterfly valve has better plasticity and toughness than cast iron butterfly valve, so cast iron butterfly valve is generally used in pipelines with relatively low pressure, and can be only used in pipeline with normal temperature. Because when the temperature or pressure increases, the cast iron butterfly valve will have a certain slight deformation, which is unfavorable for cast iron butterfly valves. Compared with cast iron butterfly valves, cast steel butterfly valves can be used in pipelines with relatively high pressure or high temperature;

Among cast iron butterfly valve, there is one kind of butterfly valve which is made of ductile cast iron, is called ductile cast iron butterfly valve or ductile iron butterfly valve; the strength of ductile cast iron butterfly valve is comparable to that of the cast steel butterfly valve. Ductile iron butterfly valve has a higher yield strength, the lower yield strength limit of ductile iron butterfly valve is 40K, while the yield strength of cast steel butterfly valve is only 36K.

In most municipal applications, such as water, salt water, steam,etc, the corrosion resistance and oxidation resistance of ductile iron butterfly valve exceed those of cast steel butterfly valves; Due to the spheroidal graphite micro-structure of ductile iron, ductile iron butterfly valve is superior to cast steel butterfly valves in terms of reducing vibration capability, so it is more conducive to reducing stress;

An important reason for choosing ductile cast iron butterfly valve is that the cost of ductile iron butterfly valve is lower than that of cast steel butterfly valves. The low cost of ductile iron butterfly valves makes this material more popular, the casting efficiency of ductile iron is higher, and the machining cost of ductile iron is reduced;

Apart from butterfly valves, we can also supply gate valves, check valves, globe valves, ball valves, hydraulic control valves, grooved fire fighting valves, strainers, etc;

for more technical parameter about those industrial valves or prices about those valves, please contact us: