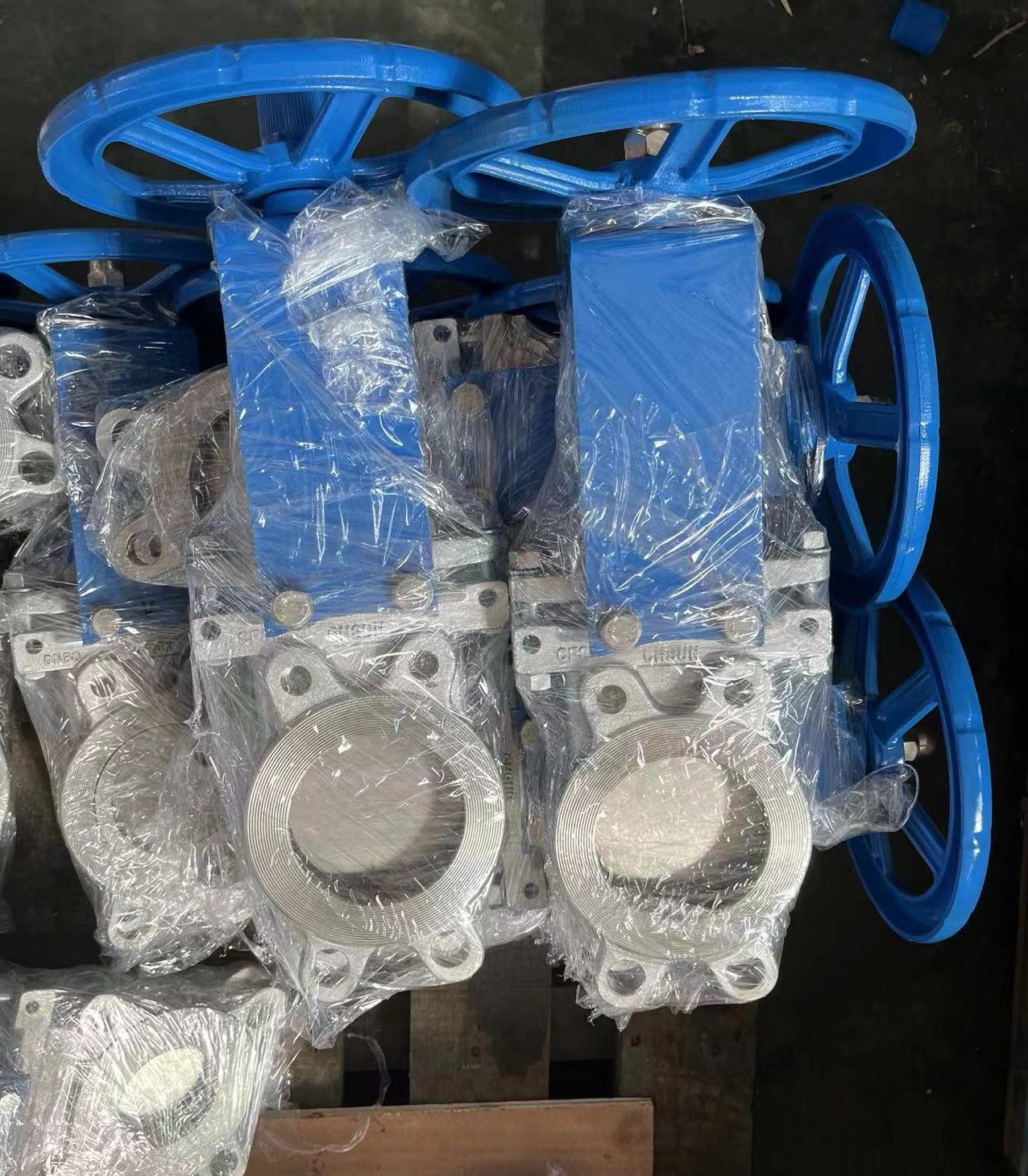

Manual knife gate valve is one kind of cutting-off industrial valve, which is widely used for mediums like paper pulp, sewage, coal slurry, ash, slag water mixture,etc.

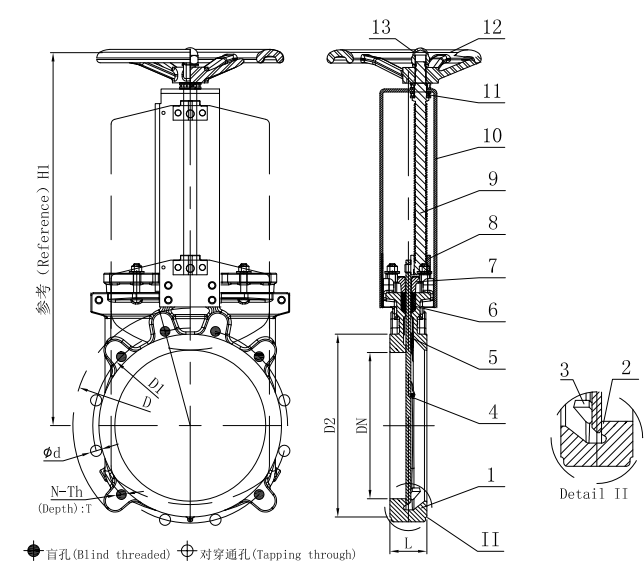

The opening and closing part of the manual knife gate valve is one blade-shaped plate, whose movement direction is perpendicular to the flow direction of the medium. There are two sealing surfaces for the valve plate of the manual knife gate valve, usually, that two sealing surfaces of the valve plate forms a wedge angle, that wedge angle varies with the parameters of the manual knife gate valve. Generally that wedge angle is 5°. the valve plate of the wedge type manual knife gate valve can be made as a whole. Since manual knife gate valve is widely used in various industries, even we can see different knife type gate valve during our daily life, then do you know what is the installation direction of the manual knife gate valve? If you don’t know, finish that article:

Installation direction of manual knife gate valve:

1. Before the installation of manual knife gate valve, we should check the inside of the valve body and the sealing surfaces of the manual knife gate valve, to make sure that there are no dirt, or sand particles.

2. When installing the manual knife gate valve, tighten the connect bolts evenly.

3. When installing the manual knife gate valve, the packing part should be pressed tightly, which can not only ensure the sealing effect of the packing, also ensure the flexible opening of the valve plate of the manual knife gate valve.

4. Before installing the manual knife gate valve, the user should check the model No., connect size, and direction of the medium of the manual knife gate valve, to ensure that manual knife gate valve can be used properly for the real working condition. The manual knife gate valve is one kind of one-way valve, which means the medium can only flow in from one direction. So that manual knife gate valve should be installed according to arrow mark on the valve body, to make sure the direction of the arrow will be the real direction of the medium flow. Otherwise, the wrong installation will affect the sealing effect of the manual knife gate valve.

5. When installing the manual knife gate valve, we should reserve the enough necessary space for the opening and closing of the manual knife gate valve.

6. If the manual knife gate valve is operated by other actuator, when we are installing the operating devices, we should install them according to the circuit diagram.

Apart from the manual knife gate valve, there are some other types of knife gate valves, their installation is always like that of the manual knife gate valve.

Types of knife gate valves:

With different operating device used, knife gate valve can be divided into manual knife type gate valve, chain wheel manual knife type gate valve, electric actuated knife type gate valve(or also called motorized knife gate valve), pneumatic knife gate valve(may also known as pneumatic cylinder actuated knife gate valve), hydraulic actuated knife gate valve, electro-hydraulic actuated knife gate valve, air-hydraulic knife gate valve,etc.

With different stem structure designed, knife type gate valve can be divided into rising stem knife gate valve and non rising stem knife type gate valve.

According to different body material used, knife gate valve can be divided into cast iron knife gate valve(CI knife gate valve in short), ductile cast iron knife gate valve(DI knife gate valve), cast steel knife gate valve(CS knife gate valve), stainless steel knife gate valve(SS knife gate valve),etc.

With different sealing material used for knife gate valve, knife gate valve can be divided into resilient seated knife gate valve(soft sealing knife gate valve), metal to metal seated knife gate valve(hard sealing knife gate valve), unidirectional sealing knife gate valve, bidirectional sealing knife gate valve.

For more details about the manual knife type gate valve, or other kinds of knife gate valves, kindly contact us: