1. How a check valve works?

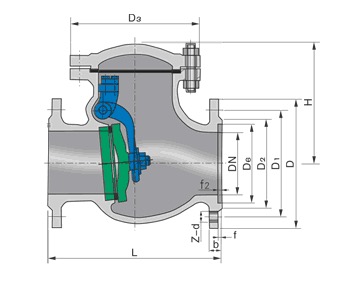

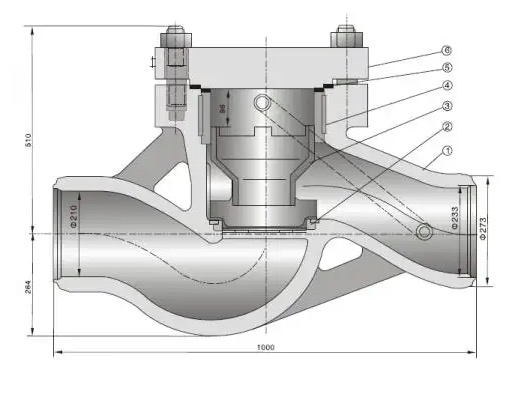

The check valve is one kind of valve which automatically opens and closes the disc driven by the flow of the medium to prevent the medium from flowing back. The check valve is also called as non return valve, cut off valve, one way valve, backwater valve.

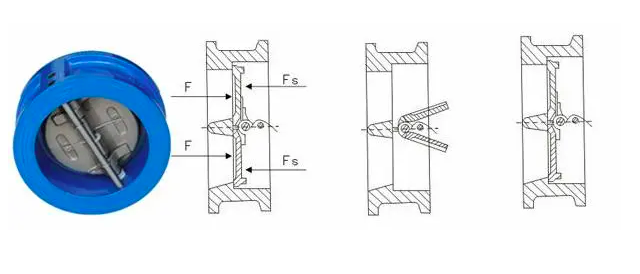

The check valve works automatically. Under the action of the fluid pressure flowing in one direction, the valve disc opens; when the fluid flows in the opposite direction, the fluid pressure and the self-weight of the disc will work on the disc to close to the valve seat, thereby cutting off the flow.

2. What is check valve used for?

The check valve is an automatic valve whose main function is to prevent the backflow of the medium, the reverse rotation of the pump and the driving motor, and the leakage of the medium in the container. Check valves may also be used on pipe lines supplying auxiliary systems where the pressure may rise above the system pressure. The check valves can be mainly divided into swing check valve(which rotates according to the center of gravity) and lift check valve(which moves along the axis line).

3. How to inspect a check valve?

The test status of the check valve: the axis of the lift check valve disc is in a position perpendicular to the horizontal; the axis of the swing check valve channel and the disc axis are in a position approximately parallel to the horizontal line.

When testing the strength of the check valve, the test medium is leaded from the inlet end to the specified value, and the other end is closed, to check whether the valve body and the bonnet are leaking or not, if there is no leaking, it is qualified.

For the sealing test of the check valve, the test medium is introduced from the outlet end, check the sealing surface at the inlet end, if there is no leakage on the packing and gasket area, it is qualified.