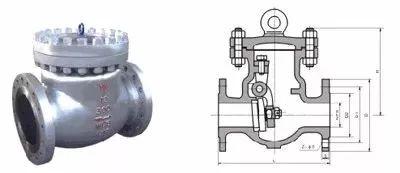

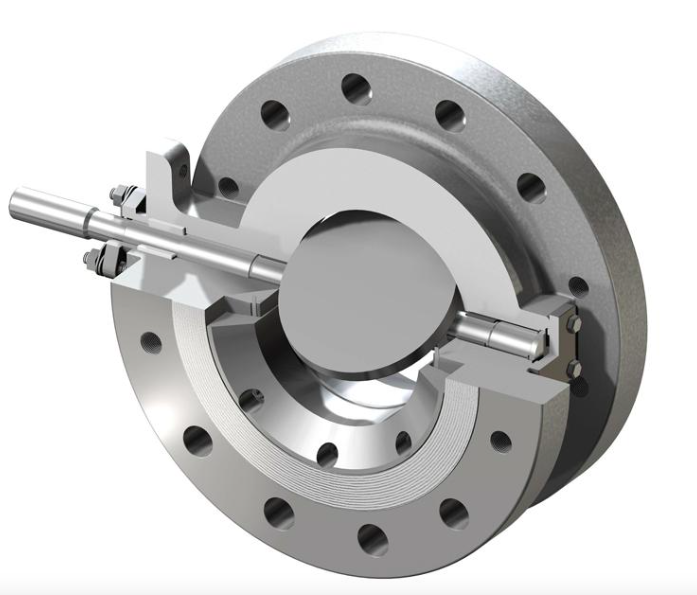

Check valve is a valve which only allows fluid to flow in one direction. Check valve is also called non return flap valve, back pressure valve, cut off valve, and one-way valve. Check valve can be divided into various types according to their different structures: such as swing type check valve, lifting type check valve, piston type check valve, butterfly type check valve and globe check valve. Today we are going to talk about the most widely used check valve-Swing check valve, and how that swing check valve works to prevent the back flow of the media in pipeline systems.

How a swing check valve works?

The disc of the swing check valve is normally pressed against the valve seat. When the fluid pressure at the inlet increases, which overcomes the weight of the valve disc and the fluid pressure at the outlet, the valve disc will open, and the pressure point at which the medium begins to flow is called the opening pressure of the check valve. As the pressure increases, the valve flap will gradually reach the fully open position. If the flow comes from the outlet side of the check valve, when the outlet pressure is greater than the inlet pressure, the valve flap closes, and the fluid can not pass through the swing check valve.