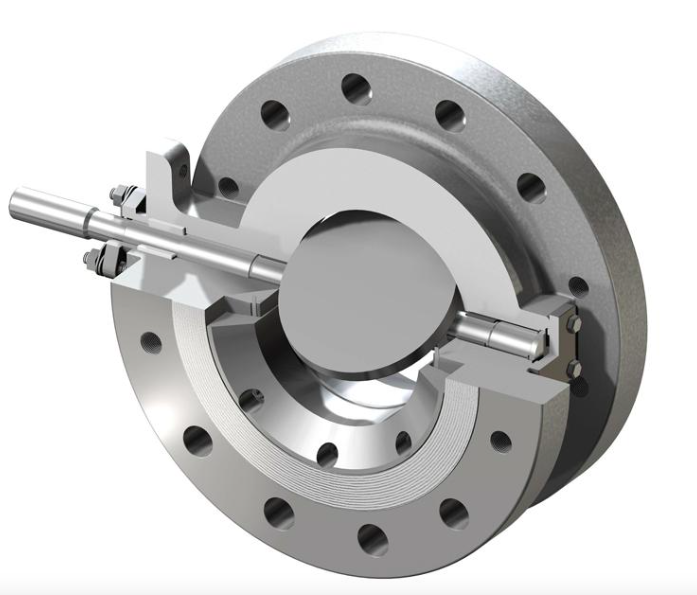

A wafer duo check valve, also called wafer duo non return valve, wafer dual doors check valve, is a specific type of check valve that is designed to provide back flow prevention in a pipeline system. It consists of two disc-like plates that are positioned parallel to each other within the valve body of the check valve. These plates are connected to a hinge mechanism that allows them to swing open and close as per the direction of fluid flow.

The wafer duo check valve is named after its wafer-style design. It is sandwiched between two pipeline flanges, and the valve body of the duo check valve has a slim profile that fits between the flanges without the need for additional pipe connections. This design eliminates the need for a separate valve body, resulting in cost-effective and space-saving installation.

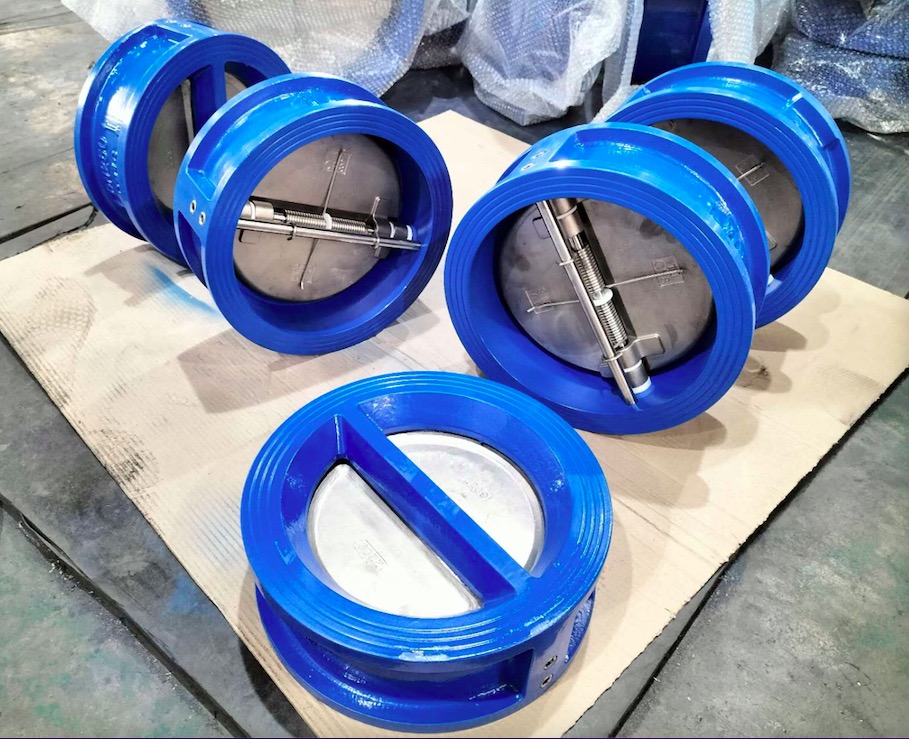

How wafer duo check valve looks like:

working principle of wafer duo check valve:

The operation of a wafer duo check valve is based on the principle of flow direction. When the fluid in the pipeline flows in the desired direction, the pressure of the flow lifts the disc plates of the duo check valve, allowing the fluid to pass through the duo check valve effortlessly. However, if the flow reverses or there is back flow, the dual disc plates of the wafer duo check valve swing back to a closed position, preventing the fluid from flowing in the wrong direction.

Key advantages of wafer duo check valve:

Wafer duo check valves offer several advantages that make them a popular choice for backflow prevention in pipeline systems. Here are some key advantages:

1. Compact and Space-Saving Design of duo check valve: Wafer duo check valves have a slim profile and are sandwiched between pipeline flanges, eliminating the need for additional pipe connections. This design saves space and allows for easy installation in tight spaces or areas with limited clearance.

2. Cost-Effective Installation of wafer duo check valve: The wafer-style design of these duo check valves eliminates the need for a separate valve body, reducing material and labor costs associated with installation. Additionally, the compact size of those wafer duo check valve results in lower shipping and storage costs.

3. Low Pressure Drop of wafer duo check valve: The streamlined design of wafer duo check valves minimizes turbulence and resistance in the pipeline, resulting in a low-pressure drop. This allows for efficient flow control while minimizing energy consumption and ensuring optimal system performance.

4. Reliable Back-flow Prevention of duo check valve: These wafer duo check valves are designed to prevent back-flow in pipeline systems. When the flow is in the desired direction, the dual disc plates open, allowing fluid to pass through. However, if there is a reverse flow or back-flow, the dual plates quickly close, preventing the fluid from flowing in the wrong direction and protecting the system against potential damage.

5. Versatile Application of wafer duo check valve: Wafer duo check valves are suitable for a wide range of applications and industries, including water and wastewater treatment, chemical processing, HVAC systems, oil and gas, food and beverage, and more. They can handle various fluids, including liquids, gases, and slurries, making them a versatile choice for different operating conditions.

6. Maintenance-Friendly of duo check valve: These wafer duo check valves are designed for easy inspection, maintenance, and replacement. The wafer design allows for quick removal and installation without disrupting the entire pipeline system, minimizing downtime and reducing maintenance costs.

7. Durability and Longevity of wafer duo check valve: Wafer duo check valves are commonly made from materials such as stainless steel, carbon steel(WCB), bronze, cast iron, or ductile iron, which provide excellent durability and resistance to corrosion, erosion, and wear. This ensures a long service life even in harsh operating environments.

wafer duo check valves offer compactness, cost-effectiveness, low pressure drop, reliable backflow prevention, versatility, maintenance-friendliness, and durability. These advantages make them an attractive choice for many industries seeking efficient and reliable flow control with minimal space and cost requirements.

Where those wafer duo check valves are applied:

Wafer duo check valves have versatile applications across various industries and systems where backflow prevention and flow control are required. Here are some common applications:

1. duo wafer check valve can be used for Water and Wastewater Treatment: Wafer duo check valves are widely used in water treatment plants, wastewater treatment plants, and sewage systems. They help regulate the flow of water, prevent backflow, and ensure the integrity of the treatment process.

2. wafer duo check valves can be applied for Chemical Processing: These wafer duo check valves are suitable for chemical processing applications where the control of aggressive and corrosive fluids is necessary. They are used to prevent reverse flow, maintain process efficiency, and protect equipment from damage.

3. EPDM lined wafer duo check valve are applied for HVAC Systems: Wafer duo check valves EPDM seated are commonly used in heating, ventilation, and air conditioning (HVAC) systems. They prevent backflow and ensure proper flow direction, contributing to efficient operation and energy conservation in HVAC applications.

4. ductile iron wafer duo check valves are used for Oil and Gas Industry: In the oil and gas industry, wafer duo check valves are utilized to control the flow of liquids and gases, preventing unwanted reverse flow that can lead to operational issues, contamination, and safety hazards.

5. those wafer duo check valves can be applied for Petrochemical Industry: Wafer duo check valves play a critical role in the petrochemical sector, where they regulate fluid flow in pipelines, storage tanks, and reactors. They ensure the safety and reliability of processing equipment and prevent cross-contamination.

6. the wafer duo check valve is used for Food and Beverage Processing: These wafer duo check valves find applications in the food and beverage industry, where hygiene and product quality are crucial. They prevent the backflow of contaminants, ensuring a clean and controlled flow of ingredients and finished products.

7. wafer duo check valve can be used in Pharmaceutical Industry: Wafer duo check valves are used in pharmaceutical manufacturing processes to maintain the integrity and purity of sensitive substances. They contribute to the prevention of cross-contamination and ensure compliance with stringent regulatory standards.

8. the ductile iron/WCB wafer duo check valve can find application in Power Generation: Wafer duo check valves are employed in power plants, including thermal, nuclear, and renewable energy facilities, to control the flow of steam, water, and other fluids during power generation processes.

9. wafer duo check valve can be used in Mining and Ore Processing: These wafer duo check valves are utilized in mining operations to prevent reverse flow and protect equipment from damage caused by abrasive slurries and corrosive chemicals. They ensure efficient and safe handling of materials.

10. those wafer duo check valve can be used for Industrial Processes: Wafer duo check valves have diverse applications in various industrial processes, including manufacturing, pulp and paper production, textile manufacturing, and more. They effectively regulate flow, prevent contamination, and ensure smooth and safe operations.

Overall, the versatile nature of wafer duo check valves makes them valuable assets in a wide range of industries, contributing to efficient flow control, protection against reverse flow, and the prevention of equipment damage and system failures.

Belo Valve is one direct exporter, wholesale supplier for wafer duo check valves, with body material: cast iron, ductile iron, carbon steel(WCB), bronze, stainless steel, and diameter range DN400-DN700, PN10/PN16, if you are looking for wafer check valves, duo check valves, wafer non return valves, dual plates check valves, etc, you can contact our sales: