Wafer type check valve is one of most widely used check valve, which is installed in vertical or horizontal pipelines to prevent the back flow of the medium. Here are three model No for wafer check valve, they are H71 wafer type check valve, H74 wafer check valve, and H76 wafer type check valve, and today we are going to discuss details about each of them:

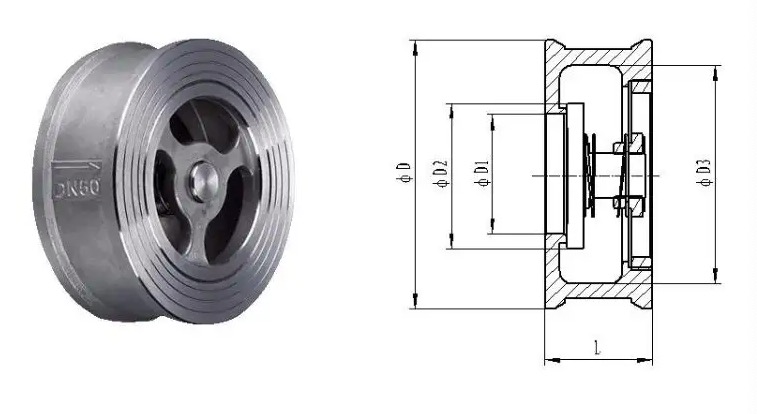

H71 wafer check valve:

H71 wafer check valve is also called lift wafer check valve, among the Model No, code 1 indicates the straight through flow channel and lifting valve disc, and the valve disc moves up and down along the center position. Due to the short closing stroke of the valve disc, and the spring loaded, the closing speed is fast, which can significantly reduce the water hammering phenomenon.

In terms of installation method, H71 lifting wafer check valve can be installed vertically or horizontally, preferably vertical installation is the best; when installing, pay attention to the arrow direction on the valve body.

The options for valve body material are 201,WCB, 304, ductile cast iron,etc.

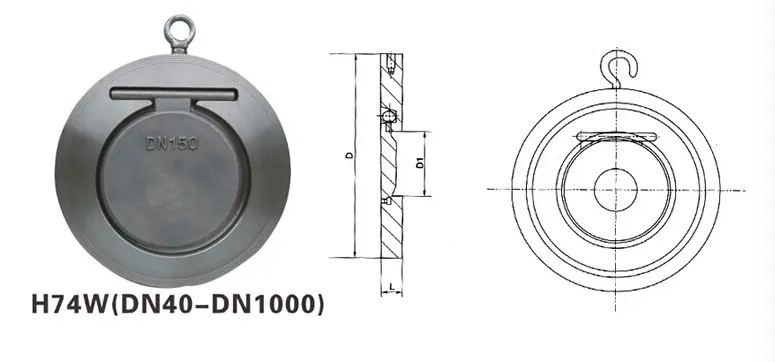

H74 wafer check valve:

H74 wafer check valve is also called single door swing wafer check valve, disc type check valve, is a thin design. The single door swing wafer check valve is light in weight, easy to install, usually installed in horizontal pipelines. When the valve flap is open, the passage channel is full open for the medium flow.

The material options for H74 wafer check valve are WCB, 304,316,etc. There are soft seal single door swing wafer check valve and hard seal single door swing wafer check valve.

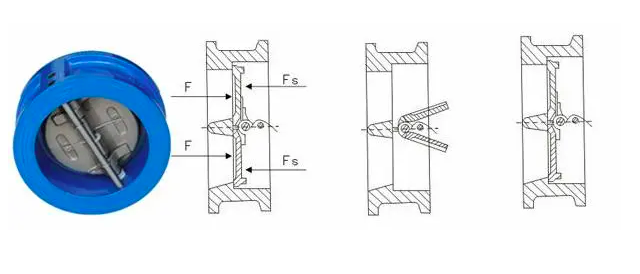

H76 wafer check valve:

H76 wafer check valve is also called butterfly type check valve, double door wafer check valve. There are two spring loaded discs(two half discs), suspended on a central vertical hinge pin, when the flow rate slows down, the torsion spring automatically reacts, making the disc close to the valve seat, which reduces the closing stroke and the closing time.

When the fluid flows back, the valve disc gradually approaches the valve seat, and the dynamic response of the valve is greatly accelerated. This reduces the effects of the water hammer, resulting in crash-free performance.