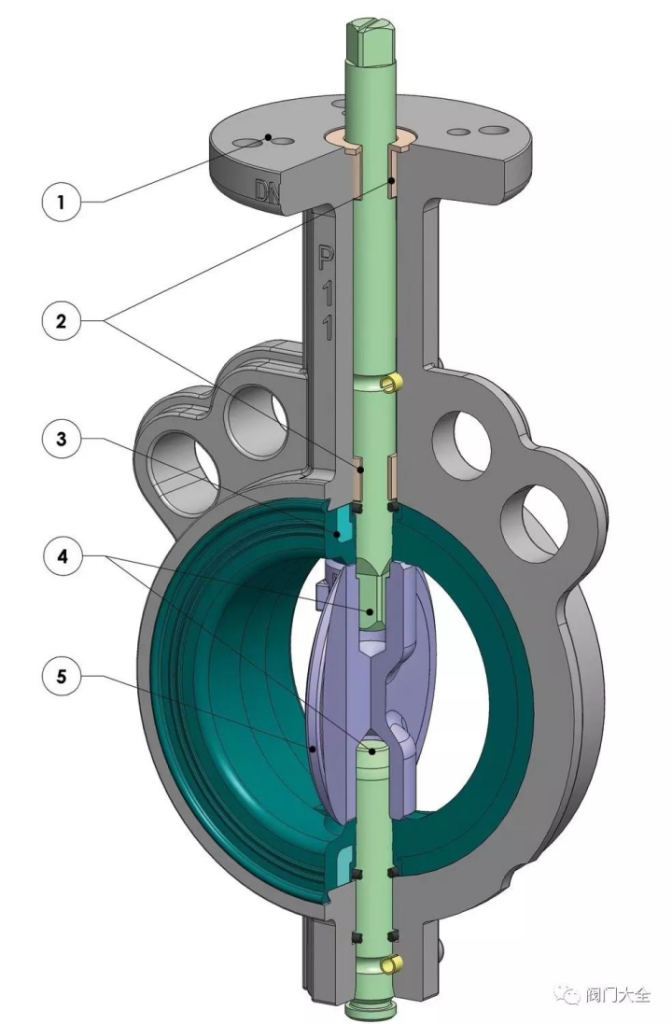

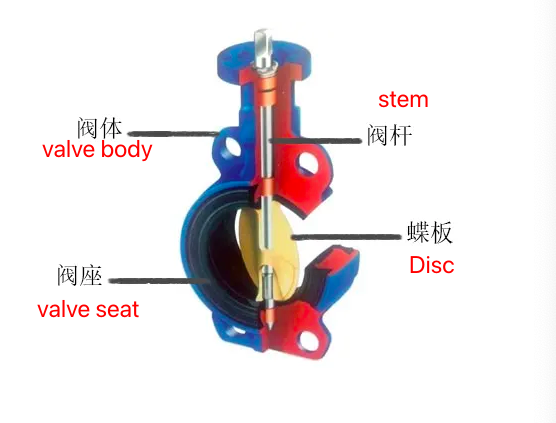

The concentric butterfly valve(also called center line butterfly valve) is a regulating valve whose closing part is a circular disc or plate. Concentric butterfly valve is mainly composed of valve body, valve stem, valve disc and sealing ring. The valve body of concentric butterfly valve is cylindrical with a short axial length and a built-in butterfly plate. The butterfly plate of the concentric butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0°and 90°.

Brief introduction of concentric butterfly valve:

At present, the concentric butterfly valve, as a component used to realize the on-off and flow control of the pipeline system, has been widely used in many fields such as petroleum, chemical industry, metallurgy, hydro-power and so on. In the known butterfly valve technology, the sealing form of concentric butterfly valve mostly adopts the sealing structure, and the sealing material is rubber, polytetrafluoroethylene,etc.

Due to the limitation of structural characteristics, concentric butterfly valve is not suitable for industries such as high temperature resistance, high pressure, corrosion resistance and wear resistance. A relatively advanced butterfly valve is a triple eccentric metal hard-sealed butterfly valve. The valve body and valve seat of triple eccentric butterfly valve are connected components, and the sealing surface layer of the valve seat is welded with temperature-resistant and corrosion-resistant alloy materials. The multi-layer soft stacked sealing ring is fixed on the valve plate. Compared with the traditional butterfly valve, triple eccentric butterfly valve has advantages of high temperature resistance, easy operation, no friction when opening and closing and compensation for sealing with the increase of the torque of transmission mechanism when closing, which improves the sealing performance of the butterfly valve and prolongs the service life;

Structural characteristics of concentric butterfly valve:

Advantages of concentric butterfly valve:

The concentric butterfly valve is small in size and light in weight, easy to disassemble and maintain, and can be installed in any position; the structure of concentric butterfly valve is simple and compact, and it can be opened and closed quickly at 90°; the sealing structure of concentric butterfly valve can realize zero leakage; different parts and materials can be selected on concentric butterfly valves to be suitable for a variety of mediums; the flow characteristics of concentric butterfly valve tend to be straight, and the adjustment performance of concentric butterfly valve is good; the number of opening and closing tests can be up to tens of thousands, and the service life of concentric butterfly valve is long.

Disadvantages of concentric butterfly valve:

The structural feature of the centerline butterfly valve is that the shaft center of the valve stem, the center of the disc and the center of the valve body are in the same position. The structure of centerline butterfly valve is simple and the manufacturing is convenient. The common rubber-lined butterfly valves belong to this category.

The disadvantages of centerline butterfly valve is that the butterfly plate and the valve seat are always squeezed and scraped, the resistance is large, and the wear is fast. In order to overcome extrusion, scratches and ensure sealing performance, the valve seat is basically made of resilient material such as rubber or PTFE, but it is also limited by temperature due to the use of sealing material, which is why people think that butterfly valves are not resistant to high temperature.

For more information or price about concentric butterfly valves, please contact us: