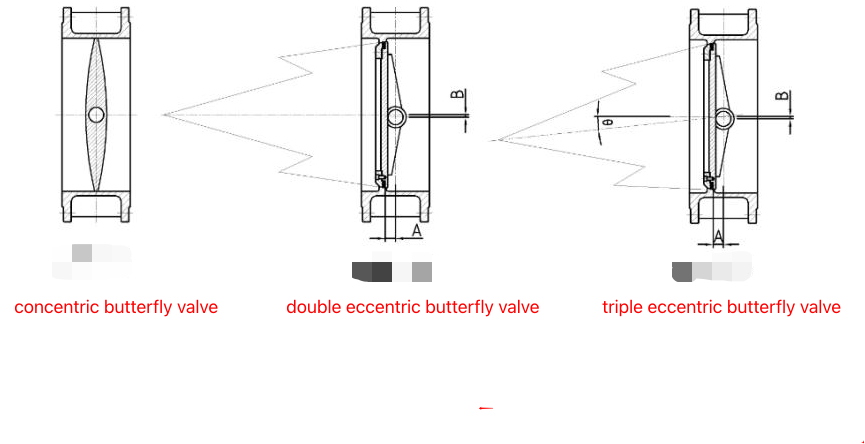

Butterfly valve is one kind of regulating industrial valve which is widely used in various pipelines to open, close and regulate the medium flow. According to structure difference, butterfly valve can be divided into concentric butterfly valve( also called center line butterfly valve), single eccentric butterfly valve, double eccentric butterfly valve(or dual eccentric butterfly valve) and triple eccentric butterfly valve( triple offset butterfly valve); today we are going to introduce concentric butterfly valve, single eccentric butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve respectively:

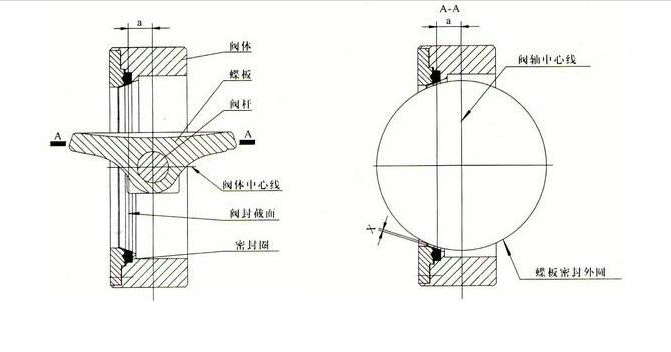

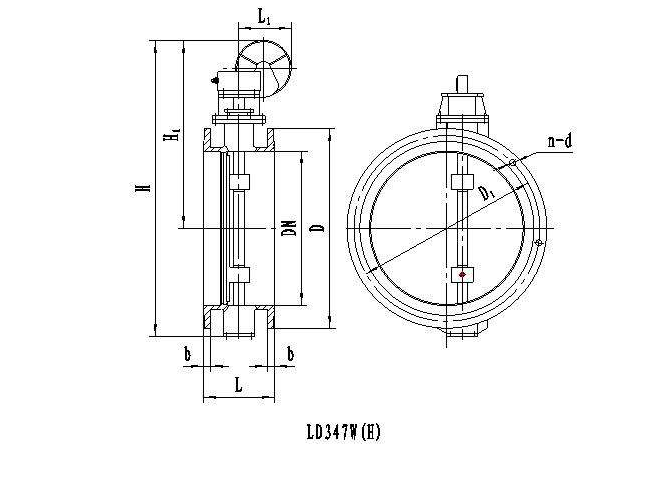

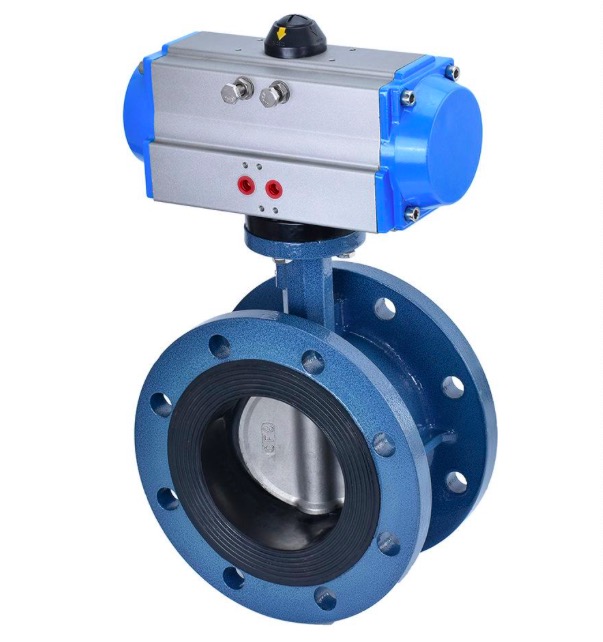

Concentric butterfly valve(center line butterfly valve):

The structure feature of the center line rubber lined butterfly valve is that the axis center of the valve stem, the center of the valve disc and the center of the valve body are in the same position. The center line butterfly valve has simple structure and is easy and convenient to fabricate; the common used center line butterfly valve includes concentric wafer butterfly valve, concentric wafer lug type butterfly valve, concentric flange type butterfly valve. For sealing material, we have rubber lined concentric butterfly valve, NBR seated concentric butterfly valve and PTFE lined concentric butterfly valve. The disadvantages of concentric butterfly valve is that the butterfly plate and the valve seat are always squeezed and scraped, the resistance is large, and the wear is fast. In order to overcome extrusion, scratches and ensure sealing performance, the valve seat is basically made of resilient materials such as rubber or PTFE. However, the application of sealing materials is also limited by temperature, which is why traditionally people thick that concentric butterfly valves are not resistant to high temperature.

Single eccentric butterfly valve:

The structural feature of the single eccentric butterfly valve is that the axis center of the valve stem deviates from the center of the butterfly plate, so that the upper and lower ends of the butterfly plate no longer become the rotation axis, which disperses and reduces the excessive extrusion between the upper and lower ends of the valve disc and the valve seat, solves the extrusion problem of the valve plate and the valve seat in concentric butterfly valves. However, in single eccentric butterfly valve, the phenomenon between the disc and the valve seat does not disappear during the entire opening and closing process of the butterfly valve, the application range of single eccentric butterfly valve is almost similar to that of the concentric butterfly valve, so it is not used that much;

Double eccentric butterfly valve:

The double eccentric butterfly valve is further improved on the basis of the single eccentric butterfly valve, and it is also the most widely used. The structural feature of double eccentric butterfly valve is that the axis center of the valve stem deviates from the center of the disc and the center of the valve body. The design of double eccentric structure enables the valve disc to break away from the valve seat immediately after the valve is opened, which greatly eliminates unnecessary excessive extrusion and scratching between the valve disc and the valve seat, relieve the opening resistance, reduces wear, and improved the service life of the valve seat. The greatly reducing of scraping enables the double eccentric butterfly valve to adopt a metal valve seat, which improves the application of double eccentric butterfly valve in the high temperature fields. However, because the sealing principle of double eccentric butterfly valve is a positional sealing structure, that is, the sealing surface of the valve seat and the disc are in linear contact, a sealing effect is produced through the resilient deformation caused by the squeezing between the disc and the valve seat, so it has high requirements for the closing position(especially for metal valve seat), and low pressure capacity. That is why traditionally it is believed that butterfly valves are not resistant to high pressure and have large leakage;

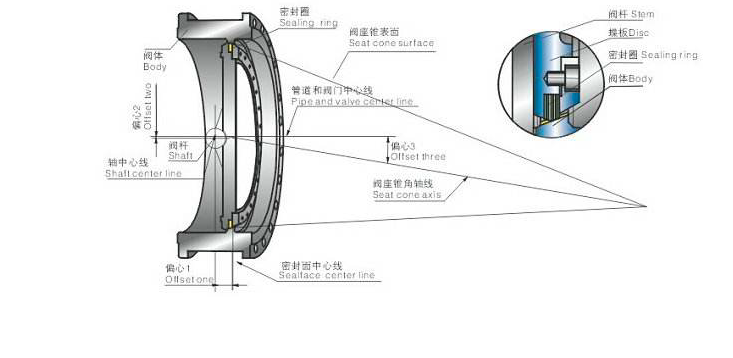

Triple eccentric butterfly valve( triple offset butterfly valve)

In order to withstand high temperature, so the metal hard sealing must be used, but the amount of leakage in metal hard sealing butterfly valve is large; for zero leakage, the soft sealing must be used, but the soft sealing material is not resistant to high temperature. In order to overcome the contradiction of the double eccentric butterfly valve, the third time eccentric design is carried out on the butterfly valve. The structure feature of tripe eccentric butterfly valve is that while the axis center of the valve stem is eccentric in double eccentric design, the conical axis of the sealing surface of the disc is deflected from the cylinder axis of the body, that is to say, after the third eccentricity design the sealing section of the disc is no longer a true circle, but an ellipse, the shape of the sealing surface is also asymmetrical, one side is inclined to the center line of the body, and the other side is parallel to the center line of the body. The big feature of this third eccentricity design is that the sealing structure is fundamentally changed, it is no longer a position seal, but a torsion seal, that is, it does not rely one the elastic deformation of the valve seat, but completely relies on the contact surface pressure of the valve seat to achieve the sealing. Therefore, the problem of zero leakage of the metal valve seat is solved. And because the contact surface pressure is proportional to the medium pressure, the high pressure and high temperature resistance is also easily solved.

For more information about concentric butterfly valves, single eccentric butterfly valves, double eccentric butterfly valve, triple eccentric butterfly valve, kindly contact us through WhatsApp or WeChat: +8615732993295: