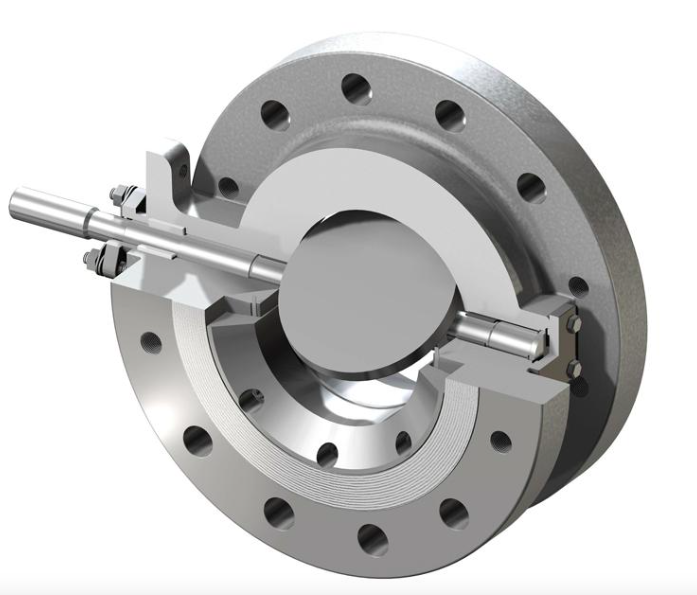

The signal butterfly valve is one kind of butterfly valve which can display the switch status of the butterfly valve. The signal butterfly valve is mainly installed on the fire fighting pipeline systems. It is an indispensable valve in the fire protection system of high rise buildings and other pipelines which need to display the valve switch status. During the construction of the buildings, the signal butterfly valves are mainly connected with the fire alarming system, because the signal butterfly valve is mainly used for fire alarming.

How to connect the signal butterfly valve:

1. open the cover of the electrical switch box of the signal butterfly valve, connect the core wire of the cable to the corresponding terminal according to the electrical control requirements, seal the cable entry, and fix the cable at the same time to prevent the cable connection from being damaged when pulled by external force;

2. When the signal butterfly valve is in the “fully closed” position, turn the closing can clockwise so that the can just touches the micro switch( a click can be heard), then tighten the screw on the signal butterfly valve cam to secure the cam;

3. When the signal butterfly valve is in “full open” position, turn the upper opening cam of the signal butterfly valve counterclockwise and adjust the opening cam in the same way as above.

4. Adjust the limit screw of the signal butterfly valve. When the valve is in the “fully closed” or “fully open” position, the limit screw should not be close to the limit plane of the worm gear, but should leave a certain gap, and then tighten the limit screw, lock the nut.

5. Close the electrical switch box cover of the signal butterfly valve. When the signal butterfly valve is in the “fully closed”position, make the pointer of the indicator point to the “0”scale on the dial, then tighten the screw to fix the pointer.

Installation tips for signal butterfly valve:

1. the following work should be done before the installation of signal butterfly valve:

A. Check carefully whether the real working requirements are consistent with the performance specifications of this signal butterfly valve.

B. Clean the inner cavity and sealing surface of the signal butterfly valve, no dirt is allowed to adhere, and do not open and close the butterfly plate before cleaning.

C. Check whether the transmission device is reliably connected with the flanges of the signal butterfly valve.

2. after the signal butterfly valve is installed, it should be inspected regularly. The main items of inspection are as follows:

A. Check whether the valve seat and O type sealing ring of the signal butterfly valve are damaged;

B. Inspect the sealing performance of the sealing surface of the valve plate of the signal butterfly valve;

C. After the signal butterfly valve is inspected and installed, there must be no jamming phenomenon when opening and closing;

D. After the signal butterfly valve is repaired and assembled, the sealing performance test should be carried out as required;

E. After each inspection of the signal butterfly valve, the situation should be recorded in detail for future reference;

3. before the installation, the signal butterfly valve should be stored in a dry place indoor, and the valve plate should be slightly opened by 4°-5°.

4. The signal butterfly valve can be installed on the pipeline at any position in the space;

5. The installation position of the signal butterfly valve should ensure the convenience of operating, maintenance and replacement.

6. The signal butterfly valve can be installed regardless of medium flow direction in the pipeline, that is, bidirectional flow is allowed.

For more information and prices for fire fighting signal butterfly valves, kindly contact us: