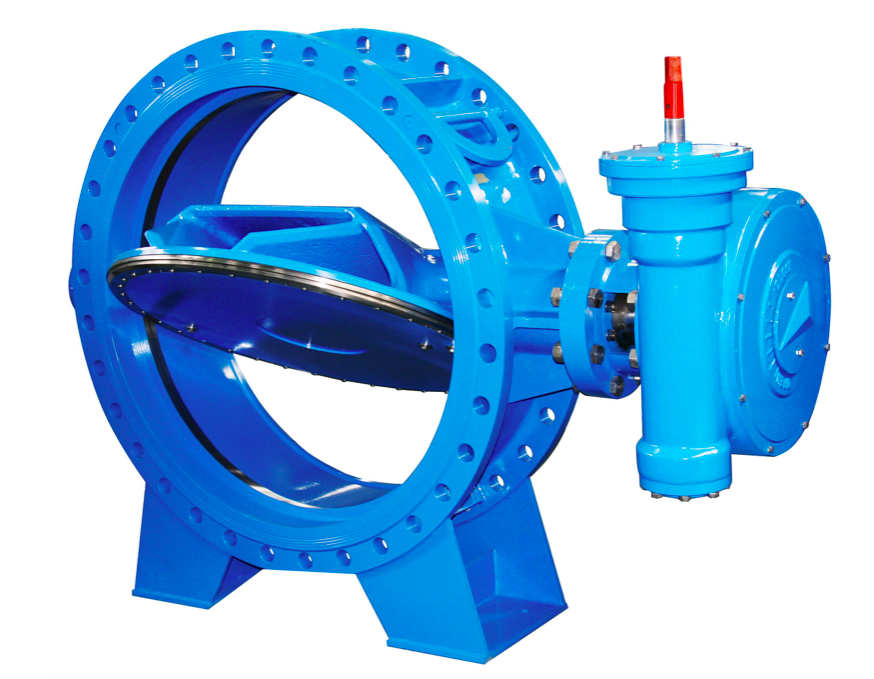

D342X-10C/16C double eccentric soft sealing flange butterfly valve is a new special design improved on the basis of the single eccentric butterfly valve. Its structural feature is that the shaft center of the valve stem deviates from the center of the disc plate and the center of the valve body. The effect of the double eccentricity enables the disc plate to leave the valve seat quickly when the valve is opening, which greatly eliminates unnecessary excessive extrusion and scratching between the disc plate and the valve seat, reduces the opening resistance and wear, improves the valve seat service life. With the scraping greatly reduced, the double eccentric butterfly valve can also use the metal valve seat, which improves the application of butterfly valve in the high temperature field. Double eccentric soft sealing butterfly valve is mainly used for water supply and drainage in water plants, power plants, steel smelting, paper making, chemical industry, food industry and other industrial systems, especially for tap water pipelines, as a adjusting and shutting off equipment.

Technical parameters for D342X-10C/16C double eccentric soft sealing butterfly valve:

Common used model No: D342X-10C/Q, D342X-16C/Q.

Nominal diameter: DN80mm-DN2000mm

Nominal pressure: 1.0-2.5Mpa

Applicable mediums: water, oils, air.

Applicable working temperature: -29℃ – 200℃.

Body material: Ductile iron, carbon steel( WCB),

Design standard: GB/T122238

Face to face standard: GB/T12221

Flange standard: GB/T 9113

Advantages of double eccentric butterfly valve:

1. due to the double eccentric structure of the double eccentric soft sealing butterfly valve, the disc plate gradually separates from the valve body during the opening process of the valve, which reduces the friction between the sealing surfaces and prolongs the service life of the valve sealing material. The double eccentric resilient valve seat sealing system can achieve bidirectional sealing performance and zero leaking effect. Double eccentric soft sealing butterfly valve has excellent gas-liquid isolation function and reliable flow regulating characteristics. The resilient sealing ring in the double eccentric soft sealing butterfly valve can be replaced easily and adjust its sealing performance.

2. The valve seat structure design of double eccentric soft sealing butterfly valve: cast steel valve body, valve seat adopts body material+butt welded corrosion resistant material on surface; cast steel valve body, valve seat adopts movable valve seat. The eccentric soft sealing butterfly valve can be opened and closed quickly, and be operated flexibly and is labor-saving; the compression degree of the sealing ring can be adjusted, so that the sealing compression can be controlled in a better state, which make the service life of the sealing valve seat longer.

for more information or price about double eccentric soft sealing butterfly valves or double eccentric metal hard sealing butterfly valves, kindly contact us:

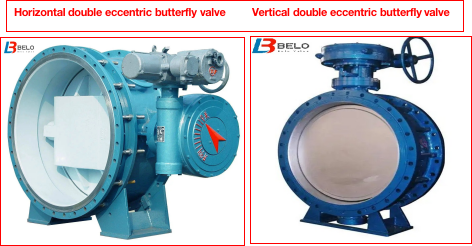

1. What is double eccentric butterfly valve?-Belo Valve

2. How do you purchase a proper industrial valve?

3. what is triple eccentric metal seal butterfly valve?-Belo Valve

4. What is D343H triple eccentric metal seal flange butterfly valve?

5. What do those Model Nos mean in butterfly valve? Like D343H,D71F,D41F,D341X…

6. The difference between single eccentric butterfly valve and concentric butterfly valve-Belo Valve

7. Common types of butterfly valves-Belo Valve

8. What does D71X-16Q/D71X-16P/D71X-16C/D71F-16Q/D71F-16P/D71F-16C in butterfly valve mean?-Belo Valve

9. D341X-16Q/D341X-16P/D341X-16C/D341F-16Q/D341F-16P/D341F-16C in butterfly valve mean?-Belo Valve