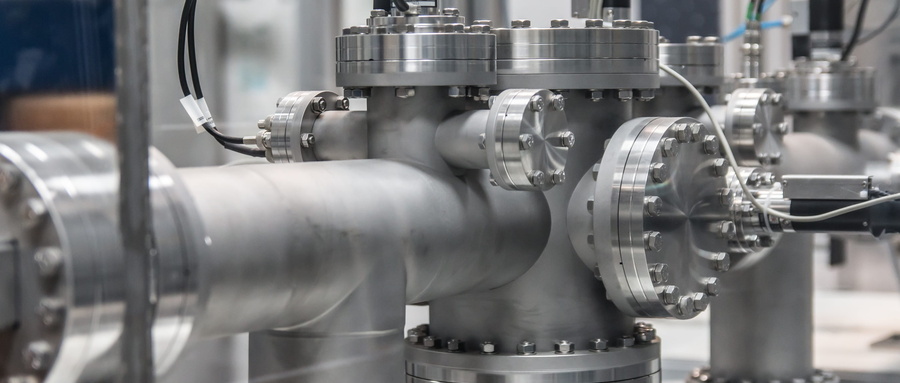

Valve is a very important switch device used in pipeline, which can be used to open, close, regulate the flow of mediums like water, oils, steam, gas, corrosive and non corrosive mediums.

According to different body material used, valves can be divided into gray cast iron valves, ductile cast iron valves, carbon steel valves/WCB valves, stainless steel valves, albronze valves, copper valves and other alloy steel valves. some of them can be used for corrosive mediums, while some of them can only be used for non corrosive mediums.

While for valves used for corrosive medium like acid base medium, anti-corrosion is the most critical part of those chemical equipment. And how to select a proper anti-corrosive valve becomes more important. If we did not choose the proper chemical valve with correct anti corrosive material, which may damage the equipment, or even cause disasters. According to relevant report, about 60% of the damage of chemical equipment is caused by corrosion. Therefore, how to select a proper anti corrosive valve scientifically is our priority. Generally, there is a misunderstanding that stainless steel valve is an ALL-MIGHTY material, which can be used for all kinds of mediums and working conditions. This is incorrect and dangerous. Today we are going to discuss how to select the anti corrosive valve material for different chemical mediums:

1. how to select valves for Sulfuric acid medium

As one of the strong corrosive medias, sulfuric acid is an important industrial raw material with a wide range of applications. Sulfuric acid with different concentrations and temperature has different corrosivity to valves. For concentrated sulfuric acid with a concentration above 80 and temperature below 80℃, carbon steel valve and cast iron valve have great corrosion resistance, but carbon steel valve and cast iron valve are not suitable for high-speed flowing sulfuric acid. That carbon steel and cast iron material are not suitable for pump valves. Ordinary stainless steel material like SS304,SS316 also have limited use for sulfuric acid medium. Therefore, the pumps and valves for transporting sulfuric acid are generally made of high-silicon cast iron and high alloy stainless steel. Fluoroplastics have better resistance to sulfuric acid, and it is a more economical choice to choose fluorine-lined pump valves.

2. how to select valves for Hydrochloric acid medium

Most metal materials valves are not resistant to hydrochloric acid corrosion, high silicon ferrosilicon containing molybdenum can only be used in hydrochloric acid below 50℃. contrary to metallic material valves, most non metallic valves have excellent corrosion resistance to hydrochloric acid, so rubber lined valves and plastic valves are the best choices for transporting hydrochloric acid.

3. how to select valves for Nitric acid medium

Most of the general metal valves are rapidly corroded and damaged in nitric acid. Stainless steel valve is the most widely used nitric acid resistant valves. It has good corrosion resistance to nitric acid with any concentration under room temperature. While the corrosion resistance of stainless steel containing molybdenum valve is not better than that of ordinary stainless steel material valves, sometimes, even worse. For high temperature nitric acid, titanium and titanium alloy material valves are generally used.

4. how to select valves for Acetic medium

Acetic acid is one of the most corrosive substance in organic acids. Generally, cast iron valves and cast steel valves will be severely corroded in acetic acid with any concentration and any temperature. While stainless steel valve has excellent corrosion resistance to acetic acid. Stainless steel 316 molybdenum valve is also suitable for high temperature dilute acetic acid steam. For high temperature and high concentration acetic acid or other corrosive mediums, high alloy stainless steel or fluoroplastic valves can be selected.

5. how to select valves for Alkali

Cast iron valves and cast steel valves are widely used in sodium hydroxide solutions below 80℃ and concentration below 30, and many petrochemical plants still use general cast iron valves or cast steel valves when the temperature is below 100℃ and concentration below 70, although there will be some corrosion damage, it is economical. Generally, the corrosion resistance of stainless steel valve to alkali liquid has no obvious advantages compared with cast iron valves and cast steel valves, as long as a small amount of iron powder is allowed to be mixed in the medium, so stainless steel valve is not recommended to be selected. For high temperature alkali liquid, titanium and titanium alloy valve or high alloy stainless steel valves are mostly used.

6. how to select valves for Ammonia

The corrosion of most metal valves and non metallic valves in liquid ammonia and ammonia water is very slight, as long as copper valves and copper alloy valves are not suitable for ammonia liquid and ammonia water.

7. how to select valves for salt brine

Generally, the corrosion rate of steel valve and iron valve in sodium chloride solution, sea water and salt water is not too high. Generally, anti corrosive coatings must be used to protect. All kings of stainless steel valves also have a very low corrosion rate, but it may cause localized corrosion due to chloride ions. Generally stainless steel 316 valves are better.

8. how to select valves for Alcohols, ketones, esters, ethers

The common alcohol mediums include methanol, ethanol, ethylene, glycol, propanol,etc. The ketone mediums include acetone, butanone, etc. Ester mediums include various methyl esters, ethyl esters,etc. And ether mediums include metthyl ether and diethyl ether, butyl ether,etc. There are basically non corrosive, and common materials valves can be used. A reasonable choice should be made according to the characteristics of the medium and relevant requirements when selecting. It is also worth noting that ketones,esters and ethers are soluble to various rubbers, so we should avoid that mistakes when choosing sealing material for the valves.

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves, etc.

if you have questions about how to select valves for your pipelines, kindly contact us: