One way valve is one kind of check valve. Their function are almost similar, but still there are some difference between check valve and one way valve. Their differences are mainly reflected in following aspects:

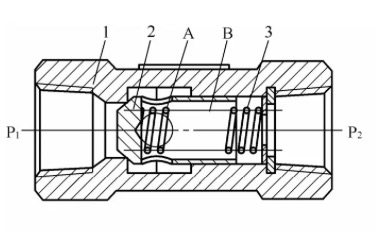

- in terms of control mode. The one way valve is a control valve, which can maintain the pressure of the pipeline by controlling the back-flow of the medium; while the check valve is a non-control valve, which is an automatic valve, although it can also play a role in maintain the pressure of the pipeline. But it is generally used to control the return of the medium, and the pressure is generally not required.

- In terms of application. One way valve is generally used in occasions which provides pressure, because the one way valve can better maintain the pressure of pipelines, such as hydraulic systems, pneumatic systems, etc. Check valve does not have strict requirement on pressure, and it is more widely used in more kinds of pipelines, or as the bottom valve in pumping units, or flue valve,etc.

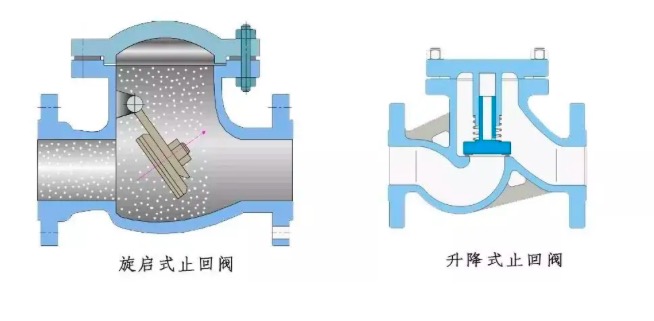

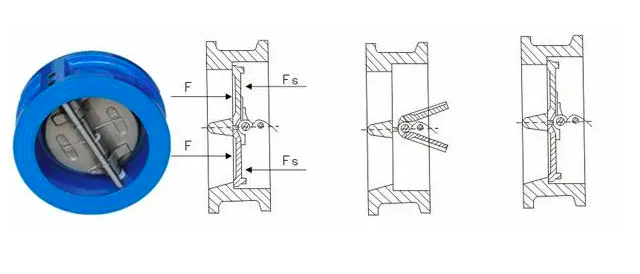

- In terms of working principle, the one way valve keeps the valve in open and closed positions through the pressure difference between the inlet and outlet, thereby preventing reverse flow; the check valve automatically opens and closes the valve disc by flow force of the medium, when the medium flows back, under the pressure of the flowing back medium and disc’s weight, the disc get back to the valve seat, to cut off the flow.

Here are the small difference between one way valve and check valve, you can choose different valves according to your real requirements;