The check valve is a valve that opens when the pipeline system is flowing forward and closes when the medium is flowing back. Check valve is mainly used to prevent the back flow of the medium, the reverse rotation of the pump and the driving motor, and the discharge of the medium in the container;

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

Definition of check valve:

The common check valve types are lifting type check valve and swing type check valve, which are also the most used in China at present;

The so-called lift type check valve means that the valve disc moves up and down relatively to the valve seat. The common lift check valve includes straight through(also called horizontal lifting check valve) and vertical lift check valve(the bottom valve of the water pump suction pipe is using vertical lifting check valve).

According to the specification JB/T308, the lift check valve is divided into straight through type lifting check valve, vertical lifting check valve and angle type lifting check valve. There is no straight through type(also called horizontal type), vertical type, and angle type for swing type check valve.

The installation of check valves:

The straight through lifting check valve can only be installed on the horizontal pipeline, vertical lifting type check valve can only be installed on vertical pipes( the direction should correct), and swing check valve can be installed on horizontal, vertical, and inclined pipes, but swing type check valves are generally installed on horizontal pipes. If swing check valves are installed on vertical pipeline, the fluid should go from bottom to top.

The advantages and disadvantages between lifting type check valve and swing check valve:

- the lifting type check valve has better sealing performance than the swing type check valve;

- The lifting type check valve has larger flow resistance than the swing type check valve;

- The swing type check valve should not be made into a small diameter valve;

For lifting type check valve and swing type check valve, that two structure check valves have phenomenon that the medium back flow speed rapidly drops from the maximum to zero when the check valve is closed, resulting in a rapid increase of the internal pressure on the side of the inlet pipe of the pipeline, which results in a water hammer phenomenon that has a destructive effect on the pipeline system. A variety of new valves have been developed to solve that issue.

What is the difference between lifting type check valve and swing type check valve:

Installation guideline for check valve:

- in pipelines, check valve should not bear any weight, large diameter check valve should be supported independently, so that the check valve won’t be affected by the pressure generated by the piping system.

- When installing the check valve, pay attention to the direction of the medium movement should be the same as the direction of the arrow marked on the body of the check valve;

- The lifting type straight disc check valve should be installed on the vertical/ straight pipeline;

- The lifting type horizontal disc check valve should be installed on the horizontal pipeline.

The lifting type check valve has good sealing performance and large fluid resistance. The horizontal type lifting check valve should be installed on the horizontal pipeline, and the vertical type lifting check valve should be installed on the straight vertical pipeline;

Conversely, the installation position of the swing type check valve is not restricted, and it can be installed on a horizontal, straight or slanted pipeline. If swing check valve is installed on a straight vertical pipeline, the flow direction of the medium should be from bottom to top;

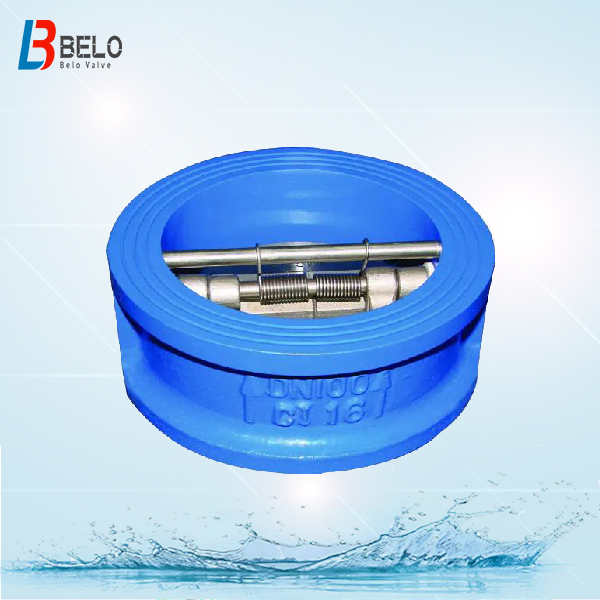

Swing type check valve, also known as non return valve, is an automatic valve which is used to prevent the back flow of the medium on the one-way flow pipeline. Swing check valve opens or closes the valve disc automatically by relying on the pressure of the medium flowing in the pipeline. Swing type check valve can be divided into single flap type swing check valve, double flap swing check valve and multiple flap type swing check valve, which is one of the most commonly used valves. Swing check valve is generally suitable for pipelines with relatively clean fluid medium and is not suitable for working conditions with high viscosity or solid particles, because those worse working conditions will make the swing check valve not to open and close flexibly, and not to achieve perfect sealing effect. The swing check valve only allows the medium to flow in one direction, which can effectively prevent the back flow of the medium and prevent accidents.

How the swing check valve works:

The disc and rocker of the swing check valve are connected together and can rotate around the pin shaft at a certain angle. When the pipeline fluid flows in from the specified direction(from left to right), the inlet pressure of the valve disc is higher than the outlet pressure. At this time, the valve disc is pushed away from the valve seat and rotates around the pin shaft to a certain position, and the swing check valve is in a open state. When the pressure difference on both sides of the valve disc is reduced to a certain level, the valve disc falls and returns to the closed state. When the fluid flows from right to left, that is, reverse flow, the pressure on the right side of the valve disc is higher than the pressure on the left side, and the force generated by the pressure difference on both sides presses the valve disc on the valve seat, and the fluid cannot pass through, then the medium cannot flow backwards;

And when the fluid pressure is greater, the sealing surface is tighter, and the sealing effect is better;

There are two kinds of straight through lifting check valve, one is with spring, one is without spring, the one with spring can be installed vertically and horizontally, and the one without spring can only be installed vertically. Vertically lifting type check valve is a swing check valve;

Straight through lift check valve generally does not have a spring, only small diameter, DN<50mm, that valve itself is closed by the weight of the valve disc. Vertical lifting check valve and swing check valve are two types of check valves with different working principles, and different shapes;

The vertical lift check valve looks like a barrel, but the middle part is fat. The straight through lift check valve is similar in shape to the globe valve and has a bonnet.