Industrial valves are widely used to control the flow of slurry, liquids and gases, which includes soft seal gate valves, hard seal gate valves, rising stem gate valves, non rising stem gate valves, resilient seated butterfly valves, metal hard sealing butterfly valves, bellows sealing globe valves, electric globe valves, soft sealing ball valves, float ball valves, one piece ball valve, two piece ball valve, three piece ball valve, hard sealing ball valves, swing type check valves, ball type check valves, double door wafer check valves, foot valves, grooved fire fighting valves, hydraulic control valves. With body material like: cast iron, ductile cast iron, carbon steel, stainless steel, bronze, brass,etc..

At present, the most commonly used industrial valves are butterfly valves and ball valves, for that two types of industrial valves, they both have their own advantages and disadvantages, but each type of industrial valve follows similar basic principles:

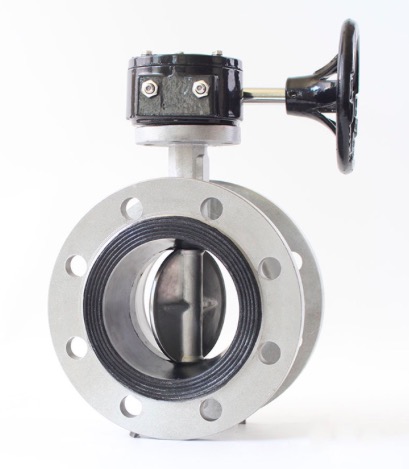

How butterfly valve works:

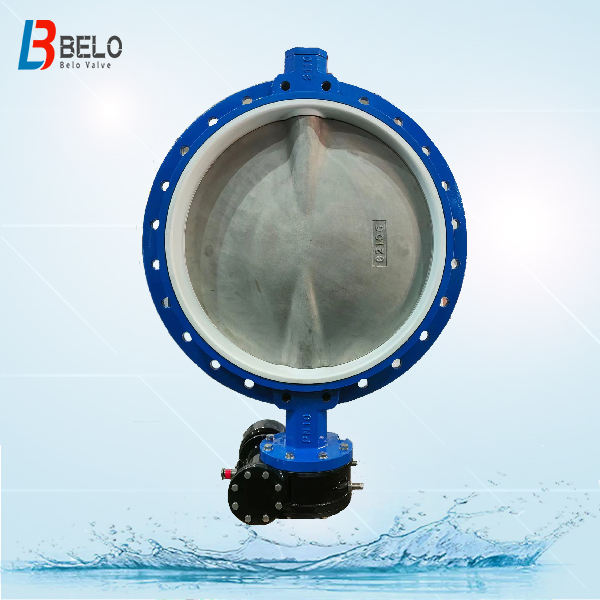

The disc of the butterfly valve is connected with the operating devices(a lever handle, worm gear box, electric actuator, pneumatic actuator) through the valve shaft which can turns 90° to open and close the butterfly valve. When the valve disc is turned in the direction of the flow, the butterfly valve opens fully, allowing the material to move across the disc. Conversely, turning the disc to the seat will block the flow.

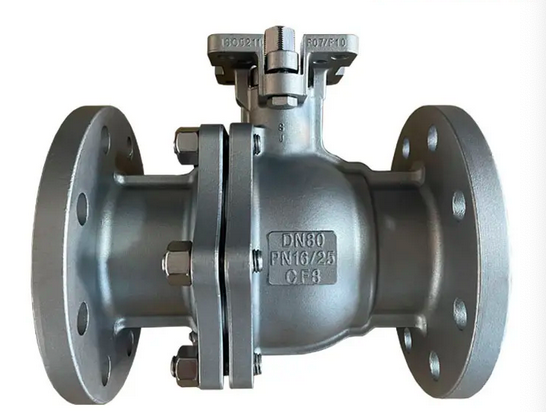

How ball valve works:

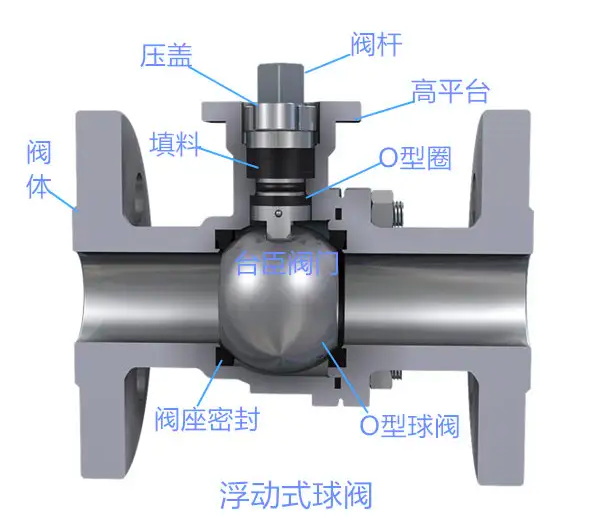

The so-called disc of the ball valve is also connected with the lever handle, or some kind of electric or pneumatic actuators through the valve stem, which can turn to achieve the opening and closing of ball valve. Unlike the butterfly valve, the disc of the ball valve is a spherical body with a hole drilled in one direction to block or release the flow. Turning the hollow half of the drilled ball towards the material to release the flow while turning the solid side of the ball towards the material to block the flow;

Applications and advantages of butterfly valve:

Butterfly valve are commonly used to regulate gas, liquid or slurry flow. Because the butterfly valve can be designed with reference to specific pressure requirements and usage patterns, so the applications of butterfly valves are very wide; some of the applications of butterfly valve includes: pipelines for water, air, gas cooling; fire protection; food and beverage production; chemical processing; pharmaceutical industry; slurry services; throttling; vacuum services,etc;

Compared with other flow management solutions, butterfly valves have more advantages:

1. butterfly valve has fast opening and closing speed;

Butterfly valve can be opened and closed faster compared with multi-turn valves. The butterfly valves can be controlled remotely to save the time, as the user does not need to travel to every valve position; 2.

2. Butterfly valves have Affordable price;

Butterfly valves are less expensive than most other valves due to lower material density;

3. butterfly valves have small size;

Because the components in butterfly valves are relatively smaller than those in other types of industrial valves, so the butterfly valve is ideal for applications where the installation space is small;

4. butterfly valves are ideal for applications requiring continuous throttling of liquids, gases or slurry;

5. Butterfly valve has low maintenance frequency;

Butterfly valves tend to require little maintenance and most of the butterfly valves have a long service life;

6. butterfly valve is easy and convenient to install;

Compared with other industrial valves, butterfly valve is generally easier to install;

7. Butterfly valves have good sealing performance;

With reliable sealing material used for valve seats like natural rubber, PTFE, NBR, the butterfly valves have great sealing performance;

Applications and advantages of ball valves:

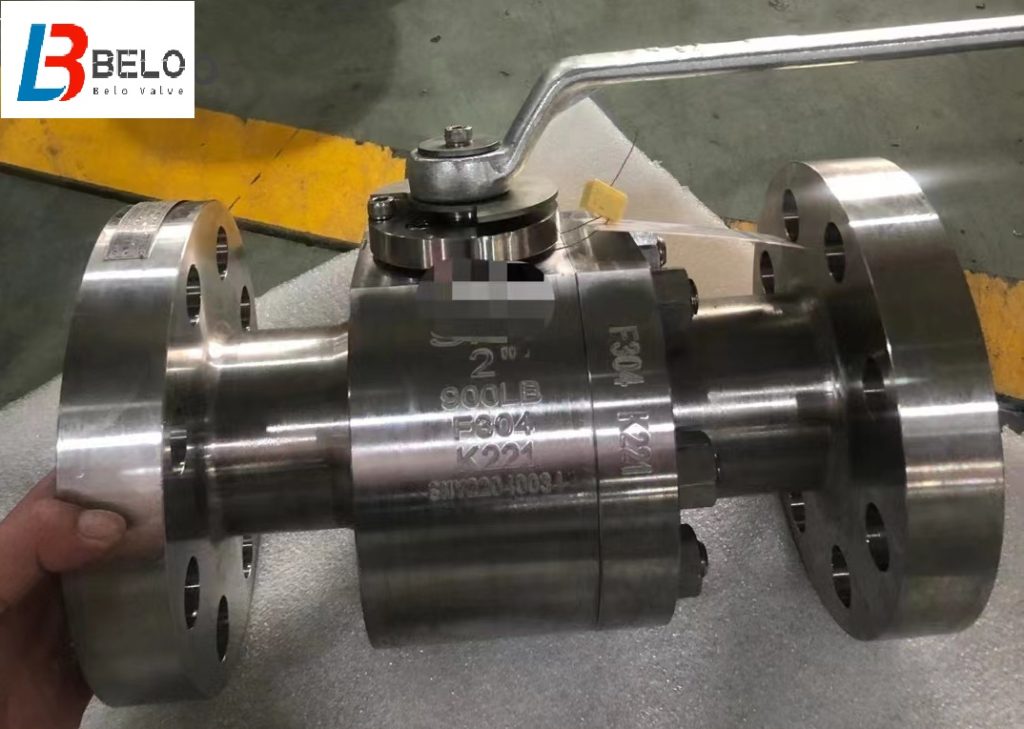

Ball valves are used in applications requiring tight sealing of liquids and gases. Like butterfly valves, ball valves can be adapted to a variety of applications. Ball valves are becoming more and more popular in many industries as they provide better control;

Applications for ball valves include: chemical processing; life science; high pressure pipeline; high temperature; food and beverage production; measurement and control; water cooling; gutters and vents;

Compared with manual operated butterfly valves, ball valves have many advantages:

1. ball valve can be open and closed very fast;

Compared with multi-turn valves, ball valve can achieve fast opening and closing. The ability to control them remotely also saves time. Because the user does not need to go to every valve position;

2. ball valve can achieve multi-way controlling:

Applications requiring superior control can benefit from the control provided by multi-port automatic ball valves;

3. ball valve has a long service time:

Ball valves are designed to withstand the pressure of intense industrial applications. To extend products life, many ball valves also allow parts to be replaced during maintenance;

4. the operation of ball valve is simple:

The ball valve can be operated automatically, which simplifies operation and simplifies existing processes;

5. ball valve have high flow rates:

Ball valves provides higher flow rate than butterfly valves when there is no flow obstructions;

The differences between ball valve butterfly valve:

1. the cut-off method of ball valve and butterfly valve is different:

the ball valve blocks the channel through the ball body to realize the cut-off of the pipeline; the butterfly valve relies on the butterfly wing, which will spread to block the flow of the pipeline to realize the sealing performance;

2. The structures of ball valve and butterfly valve are different:

Ball valve is composed of valve body, valve trim and valve stem, and only some parts can be seen with the naked eye; butterfly valve is composed of valve body, valve seat, valve plate, and valve stem, and all accessories are exposed outside. Therefore, it can be seen that the sealing performance of the butterfly valve is not as good as that of the ball valve;

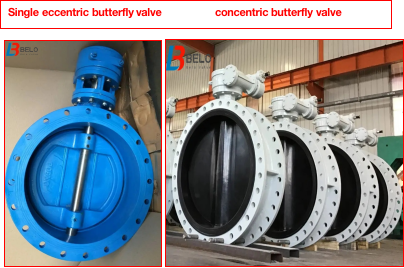

Butterfly valves are also divided into soft sealing butterfly valve and hard sealing butterfly valve. Butterfly valve is relatively simple, can only be used in low pressure environment, the highest pressure can only reach 64KG. Compared with the ball valve, the ball valve can be up to about 100KG;

3. the working principle of ball valve and butterfly valve is different:

The ball valve has 90 degree rotation action, just because its opening and closing part is a sphere, it can be opened or closed only by operating a 90 degree rotation, while ball valve is suitable for switching. But now V-shaped ball valve can be used to regulate or control the flow;

The butterfly valve is a kind of industrial valve that uses the disc type opening and closing member to reciprocate about 90 degrees to open, close or adjust the flow of the medium. Butterfly valve has good function of adjusting the flow, and is one of the fastest-growing valve varieties.

For the price or more technical parameters about ball valves or butterfly valves please contact us: