Valve is one important device used in various industrial pipelines, which can be used to connect, cut off and regulate the medium flow.like butterfly valves, gate valves, ball valves, check valves and globe valves. Most of the valves include valve body, valve shaft, valve disc, valve sealing seat, and operating device. And today we are going to discuss the sealing materials for valves.

The most important part of the valve sealing is the sealing seat of the valve, also called the valve sealing ring, which is an important part of a valve sealing pair. The valve sealing seat is connected with the medium directly. The medium in the pipeline include water, gas, particulate matter, acid and alkaline substances,etc. With different mediums, the valve should use the different sealing materials, so that we can make sure that sealing material can be suitable for the medium. Then how many types of sealing materials we have for valves? Now lets figure it out together:

Common Types of Sealing Materials for Valves

The valve sealing materials can be divided into two categories: one is metal(hard sealing) sealing material and the other is non metallic sealing material(also called soft sealing material):

3 Types of Non metallic sealing materials for valves

1. synthetic rubber

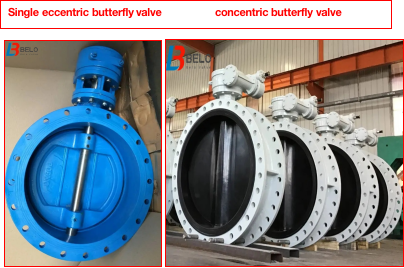

Compared with natural rubber, synthetic rubber sealing material has better oil resistance, temperature resistance, acid and alkali resistance. Generally speaking, the operating temperature of synthetic rubber is t≤150℃, and the operating temperature of natural rubber sealing material is t≤60℃. synthetic rubber sealing material is usually used as sealing seat material for butterfly valves(like soft sealing concentric butterfly valve,soft sealing eccentric butterfly valves), gate valves(like soft sealing rising stem gate valves and soft sealing non rising stem gate valves), globe valves, check valves and other industrial valves, whose nominal pressure is PN≤16KG.

2. PTFE

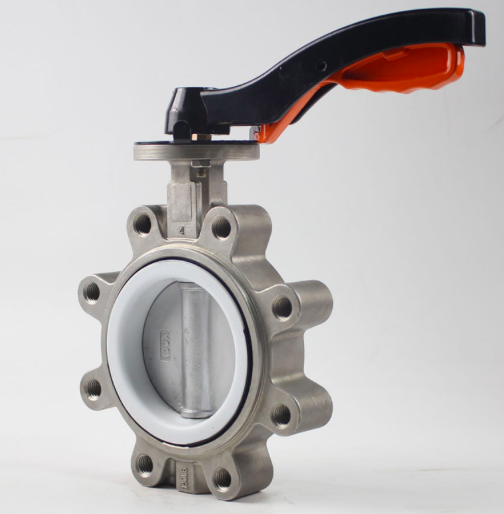

Compared with rubber sealing materials, like EPDM, PTFE sealing material has better corrosion resistance, and is mostly used for working temperature t≤232℃,nominal pressure PN≤64KG. PTFE sealing material can be used for butterfly valve( like PTFE lined concentric wafer butterfly valves, PTFE lined concentric flange butterfly valves, PTFE lined concentric lug type butterfly valves), gate valves( PTFE seated soft sealing gate valves), globe valves, and ball valves.

3. Nylon

The advantages of Nylon are its low coefficient of friction and good corrosion resistance. Nylon sealing material is mostly used for ball valves, globe valves with operating temperature t≤90℃,and nominal pressure PN≤32KG.

5 types of metal sealing material used for valves

1. Gray cast iron

Gray cast iron can be used as sealing material for butterfly valves, gate valves(metal to metal seated non rising stem gate valves, metal to metal seated knife type gate valves), globe valves, plug valves,etc with operating temperature -15℃≤t≤200℃, and nominal pressure PN≤16KG.

2. Ductile cast iron OR ductile iron(DI in short)

Ductile cast iron can be used as a sealing material in butterfly valves, gate valves, check valves and ball valves with operating temperature -30℃≤t≤350℃ and nominal pressure PN≤40KG.

3 . Copper Alloy

Commonly used materials for copper alloys are 6-6-3 Tin bronze and 58-2-2 manganese brass. Copper alloy has good wear resistance and is suitable for water and steam with t≤200℃, and nominal pressure PN≤16KG. Copper alloy can be used as sealing material for gate valves, globe valves, check valves, plug valves,etc.

4. chromium stainless steel

The commonly used chromium stainless steel are 2Cr13 and 3Cr13, which have good corrosion resistance. Chromium stainless steel sealing material is often used on valves for mediums such as water, steam and petroleum with t≤450℃, and nominal pressure PN≤32KG.

5. chromium-nickel-titanium stainless steel

The commonly used chromium-nickel-titanium stainless steel is 1Cr18Ni9Ti, which has good corrosion resistance, erosion resistance and heat resistance. It is suitable for steam, nitric acid and other medium with temperature t≤600℃, and nominal pressure PN≤60KG. chromium-nickel-titanium stainless steel can be used as sealing material for butterfly valves( mostly like double eccentric metal sealed butterfly valves and triple eccentric butterfly valves), globe valves, ball valves,etc.

Those materials introduced above are the commonly used nonmetallic and metal sealing materials for valves, like butterfly valves, gate valves, check valves, globe valves, ball valves, plug valves,etc, with mediums like water, waste water, steam, natural gas,oils, and various in-corrosive and corrosive mediums. According to the different medium conditions in the pipeline, like the temperature, pressure and corrosivity, the corresponding sealing material can be used to achieve the best sealing performance of the valve.

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves, etc.

If you want to know more technical information about those valves, kindly contact us: