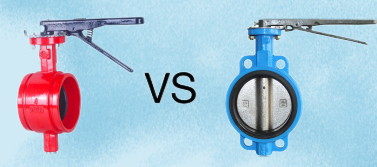

Butterfly valve is one kind of widely used industrial valve, which can be used in the pipeline system to connect, cut off and regulate the flow rate. According to different structure design, there are concentric butterfly valve and eccentric butterfly valves. Among concentric butterfly valve, with different end connections, there are concentric wafer type butterfly valve, concentric wafer lugged butterfly valve, concentric flange type butterfly valve and concentric grooved type butterfly valve. Different from other concentric butterfly valves, grooved butterfly valves are widely used in fire fighting systems. Today we are going to introduce the difference between wafer butterfly valve and grooved butterfly valve:

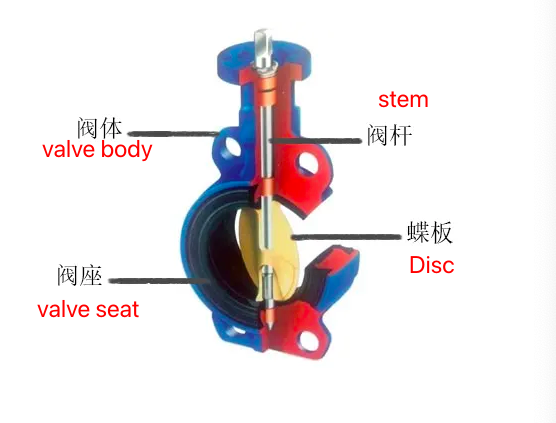

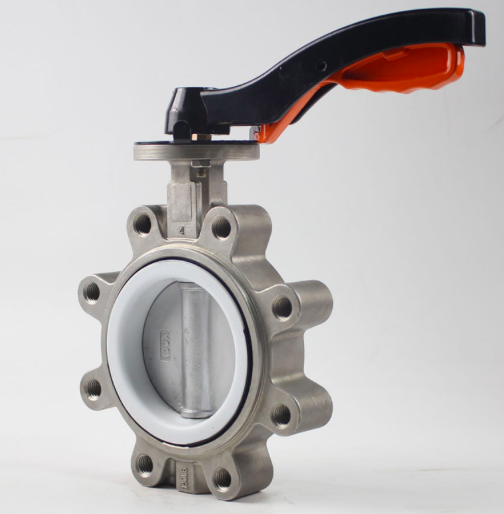

About wafer butterfly valve:

There are many types of wafer butterfly valves, and they are widely used in different various industrial pipeline systems to open, close and regulate the medium flows. The wafer butterfly valve has a short body structural length, and a simple structure, and has only few simple components: valve body, valve disc, valve stem, valve seat, operating device,etc.

For different body material used, there are cast iron wafer type butterfly valve, ductile iron wafer type butterfly valve, cast steel wafer type butterfly valve, and stainless steel wafer type butterfly valve. Concentric wafer type butterfly valves are cheap in price and easy to install. They can be directly connected to the two flanges of the pipelines with a few bolts.

Concentric wafer type butterfly valves are widely used in water system pipelines. Wafer type butterfly valves are used in building water supply and drainage, municipal water, water conservancy projects and other pipelines, and even some oil-passing pipelines will also use wafer type butterfly valves.

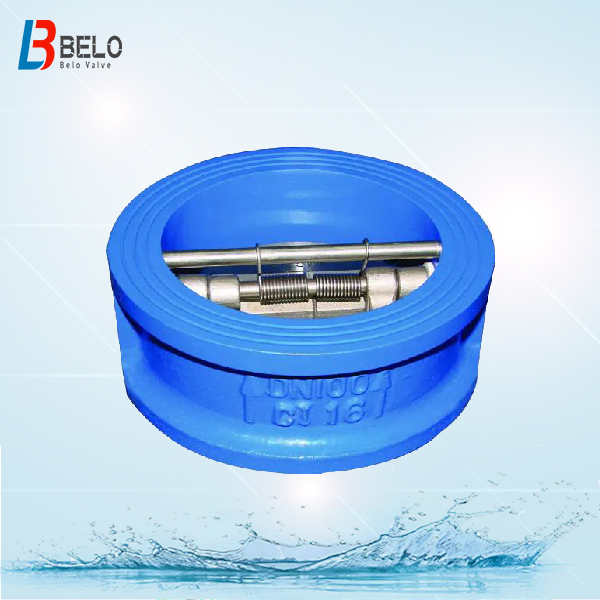

About grooved butterfly valve:

Grooved butterfly valves are mainly used in fire fighting pipelines, while wafer type butterfly valves are used in ordinary pipelines.

Grooved butterfly valve has simple structure, is easy to operate, can be driven by manual lever handle or worm gear box. The price of the grooved butterfly valve is low, and the body of grooved butterfly valve is small, mostly are made of ductile iron material. The installation of grooved butterfly valve is simple, clamps can be used to connect the grooved butterfly valve with the pipeline, no flanges and bolts are required;

Grooved butterfly valves are mainly used in fire protection pipeline. Most of these pipelines have no practical application after installation, so those grooved butterfly valves do not need to be replaced frequently.

Apart from grooved butterfly valves, we also have grooved gate valves, grooved check valves, grooved Y type strainers, etc for fire protection systems:

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

for more information about those industrial valves, do not hesitate to contact us: