Ductile iron GGG50 rubber ball type check valves are one kind of check valve also called non return valve, widely used in various industries due to their exceptional reliability, durability, and versatility. Ductile iron GGG50 rubber ball type check valves offer numerous advantages, including high strength, corrosion resistance, low maintenance, versatility, and noise reduction. These valves ensure reliable and uninterrupted flow control while minimizing the risk of system damage or failure. When selecting check valves for industrial applications, considering the benefits of ductile iron GGG50 rubber ball type check valves is a prudent choice.

What is a check valve or non return valve?

A check valve, also known as a non-return valve or one-way valve, is a mechanical device used in piping systems to allow the flow of fluid in one direction while preventing backflow in the opposite direction. The primary function of a check valve is to ensure that fluid flows in a single direction, preventing reverse flow which can lead to system inefficiencies, damage, or potential hazards.

Check valves typically consist of a movable mechanism called a disc or a ball that opens and allows flow when the fluid is moving in the desired direction. When the flow stops or reverses, the disc or ball is forced against a seat, creating a seal that prevents backward flow.

The sealing mechanism can be achieved through various designs, including swing check valves, lift check valves, duo wafer check valve, rubber disc check valve and rubber ball check valves.

The selection of a check valve depends on factors such as the type of fluid, pressure, flow rate, and application requirements. Check valves are commonly used in various industries, including water and wastewater systems, oil and gas pipelines, chemical processing plants, HVAC systems, and many others.

Some check valves for your reference:

Common used types of check valves:

There are several types of check valves commonly used in various industries based on their design and functionality. Here are the most common types:

Swing Check Valve:

Swing check valves have a hinged disc that swings freely on a horizontal or vertical axis. When the fluid flows in the desired direction, the disc swings open, allowing the flow. When the flow stops or reverses, the disc swings back and closes to prevent backflow. These swing check valves are suitable for applications with moderate flow rates.

Lift Check Valve:

Lift check valves have a disc or piston-like component that lifts off the seat as the flow increases, allowing fluid to pass through. When the flow stops or reverses, the disc or piston settles back onto the seat, preventing backflow. Lift check valves are commonly used in applications with high flow rates and pressure.

Rubber Ball type Check Valve:

Rubber Ball type check valves use a spherical or cylindrical-shaped ball as the sealing element. The rubber ball is pushed against the seat by the force of the forward flow, creating a seal to prevent back flow. When the flow stops or reverses, the rubber ball moves away from the seat, allowing fluid to flow freely. rubber Ball type check valves are suitable for both high and low flow applications.

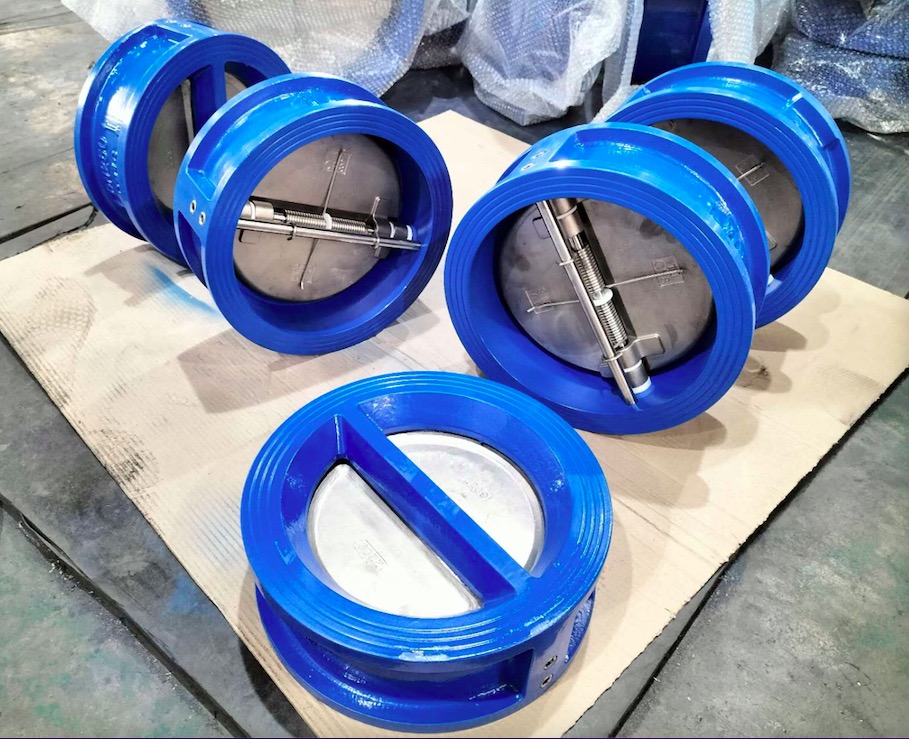

Duo Check Valve wafer type:

Duo check valves, also known as double door check valve or wafer check valves, consist of two independently operating doors or discs that close against each other when flow reversal occurs. This design allows for minimal pressure drop and prevents backflow effectively. Duo check valves wafer type are commonly used in applications where space and weight are important considerations.

Tilting Disc Check Valve:

Tilting disc check valves have a hinged disc with a central pivot. When the flow is in the desired direction, the disc tilts and allows fluid to pass through. When the flow stops or reverses, the disc returns to its closed position, preventing backflow. These tilting disc check valves are often used in high-flow and high-pressure applications.

Rubber disc check valves, also known as rubber flap check valves or rubber duckbill check valves, are specifically designed check valves that ensure the flow of fluid in one direction while preventing back flow in the opposite direction. These rubber disc check valves utilize a flexible rubber disc or flap as the sealing element, which opens and closes based on the pressure of the fluid.

These are just a few examples of the different types of check valves available. The selection of a check valve depends on factors such as flow rate, pressure, application requirements, and the type of fluid being handled. It’s important to choose the appropriate type of check valve to ensure optimal performance and system reliability.

Today we are going to introduce some information about those rubber ball type check valve ductile iron GGG50 body material, including how rubber ball type check valves works, key features about ductile iron rubber ball type check valves, and where those ductile iron rubber ball type check valves are applied:

How ductile iron GGG50 rubber ball type check valve works:

The ductile iron GGG50 rubber ball type check valve operates using a simple yet effective mechanism that allows for fluid flow in one direction while preventing backflow in the opposite direction. Here’s how it works:

the rubber ball check valve allows the media to Flow in the Desired Direction:

When the fluid flows in the desired direction, the flow pressure pushes the rubber ball away from the valve seat of the check valve, creating an opening flow channel. This allows the fluid to pass through the rubber ball check valve freely, similar to how a one-way door operates.

the rubber ball check valve can Prevent Backflow:

If the flow stops or reverses, the rubber ball is forced back against the valve seat by the fluid pressure. The elastic nature of the rubber ball enables it to form a tight seal against the seat, effectively preventing any backflow of fluid.

Self-Aligning Seal:

One of the key advantages of the rubber ball design of that type check valve is its ability to self-align when closing. Regardless of the entry angle or direction of the fluid flow, the rubber ball will automatically position itself against the seat, ensuring a secure seal. This self-aligning feature eliminates the need for precise alignment during installation and ensures reliable sealing performance.

Anti-Clogging and Self-Cleaning:

Since the rubber ball in the check valve is a flexible component, it can easily deform and move in response to debris or solid particles in the fluid. This design prevents clogging or obstruction of the valve by allowing any foreign matter to flow past the rubber ball. Consequently, the ductile iron GGG50 rubber ball type check valve is self-cleaning, reducing the risk of maintenance and allowing for uninterrupted flow.

Pressure Drop:

It’s important to note that like any check valve, the ductile iron GGG50 rubber ball type check valve causes a small pressure drop due to its design. The pressure drop is typically minimal, but it may vary depending on the valve size, flow rate, and other factors. Considerations should be made to ensure that the pressure drop from the valve does not significantly impact the system’s performance.

the ductile iron GGG50 rubber ball type check valve operates by using a rubber ball as a sealing mechanism. The rubber ball opens to allow fluid flow in the desired direction and closes to prevent backflow. This design offers self-aligning sealing, anti-clogging capabilities, and minimal pressure drop, making it an effective and reliable choice for a variety of applications.

Key features of ductile iron rubber ball check valve:

High Strength and Durability:

Ductile iron, also known as nodular or spheroidal graphite iron, offers superior mechanical properties compared to traditional cast iron. Its increased tensile strength and impact resistance make it an ideal material for manufacturing check valves. Ductile iron GGG50 rubber ball check valves are highly resilient and can withstand high pressure and temperature conditions, ensuring long-term performance and reliability.

Corrosion Resistance:

The rubber ball inside the check valve acts as a sealing mechanism when it is pressed against the seat, preventing fluid back flow. Ductile iron GGG50 rubber ball check valves have an epoxy or a fusion-bonded powder coating on the inner and outer surfaces, providing excellent resistance against corrosion caused by aggressive or corrosive media. This feature makes them suitable for applications in industries such as water treatment, chemical processing, and wastewater management.

Low Maintenance:

The rubber ball design of GGG50 ductile iron rubber ball type check valves eliminates the need for lubrication and minimizes the risk of jamming or sticking. Unlike traditional swing check valves, rubber ball type check valves are self-cleaning, preventing the accumulation of debris or sediments that can hinder valve operation. This design ensures low maintenance and reduces downtime for crucial industrial processes.

Versatility and Adaptability:

Ductile iron GGG50 rubber ball check valves are available in a wide range of sizes, pressure ratings, and end connections, allowing for seamless integration into various piping systems. These rubber ball check valves can handle different flow rates and are suitable for both horizontal and vertical installations. Additionally, they can be customized with accessories such as limit switches or bypass valves to meet specific application requirements.

Noise and Water Hammer Reduction:

The rubber ball serves as a cushioning element in ductile iron GGG50 rubber ball type check valves. During the closure process, the rubber ball absorbs the kinetic energy of the fluid, reducing water hammer effects and preventing noise generation. This feature is especially crucial in applications where sudden changes in flow direction or velocity occur, preventing pipe damage and extending the lifespan of the check valve.

If you are looking for those ductile iron rubber ball check valves, you can contact us direct: