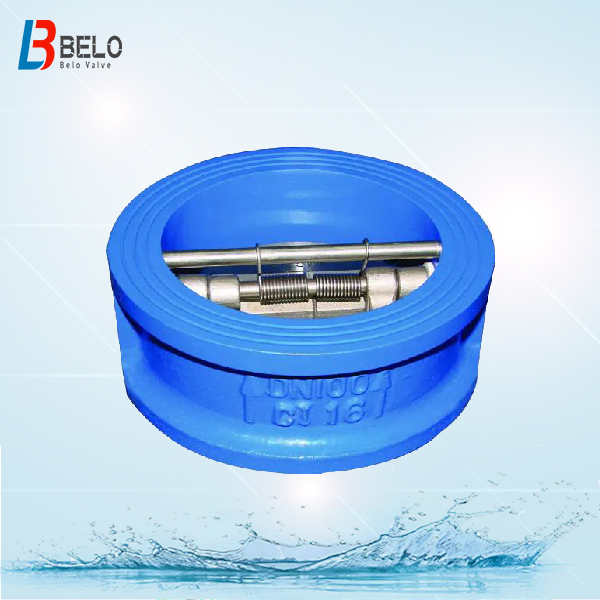

Ball type check valve is a combination of the ball valve and check valve. It consists of a valve cover, a rubber ball, a cone and other parts. The ball type check valve’s working principle is to use the rubber ball to roll in a short stroke in the ball cover to realize the opening and closing of the check valve, thereby, which can realize the anti-reverse flow effect of the check valve.

Maintenance of ball type check valve:

- the dis-assembly and decomposition operation can only be carried out after it is confirmed that the upstream and downstream pipelines of the ball type check valve have been depressurized;

- During dis-assembly and reassembly, attention must be paid to prevent damage to the sealing surfaces of valve parts, especially non-metallic parts. Special tools should be used when removing the O type ring.

- The bolts on the ball type check valve flange must be tightened symmetrically, gradually and evenly during assembly.

- The non-metallic parts of the ball type check valve should be removed from the cleaning agent immediately after cleaning, and should not be soaked for a long time;

- After cleaning, it needs to be assembled after the cleaning agent on the wall surface has evaporated( it can be wiped with a silk cloth which has not been soaked in the cleaning agent), but it should not be left for a long time, otherwise it will rust and be polluted by dust;

- The new parts of the ball type check valve also need to be cleaned before assembly;

- When the ball type check valve is assembled, it is not allowed to have metal chips, fibers, grease(except for those required to use), dust and other impurities, foreign objects, etc, to contaminate, adhere or stay on the surface of the parts or enter the inner cavity.