Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive medium, mud, oil, liquid metal and radioactive medium. Since it is very important to choose the most suitable valves for plumbing systems, so it is also very important to understand how many types of valves there are in plumbing systems, and what are the characteristics of those valves, how to select the right valves for your plumbing system, or what kind of valve should be used, gate valve, butterfly valves, ball valve, check valves, globe valves, control valves, throttle valves, grooved valves, etc.

how many types of valves there are in plumbing systems?

1.Valves can be divided into two types: one is automatic valves, the other is power driving valves.

1.1. Automatic valve

Automatic valve is the valve which operates by itself depending on the flow force of the medium( like liquid, gas), such as check valves, safety valve, regulating valve, drain valve, pressure relief valve.

1.2. Power driving valve:

Power driving valve is the valve which operates with the help of manual device, electric actuator, hydraulic actuator, pneumatic actuator. Such as gate valve, globe valve, throttling valve, butterfly valve, ball valve, plug valve;

2. According to structural characteristics, according to the direction of movement of the closing part relative to the valve seat, valves can be divided into:

2.1. stop valve: the closing part moves along the center of the seat.

2.2.gate valve: the valve disc moves along the line vertical to the seat center.

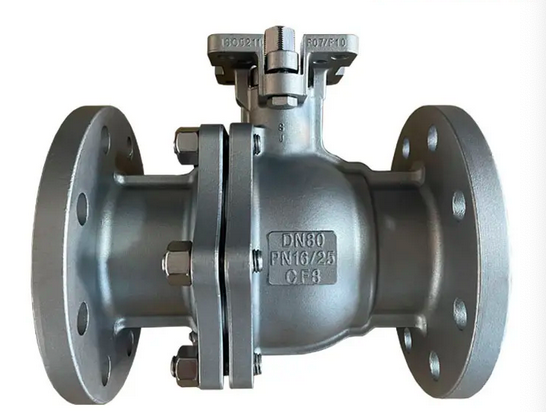

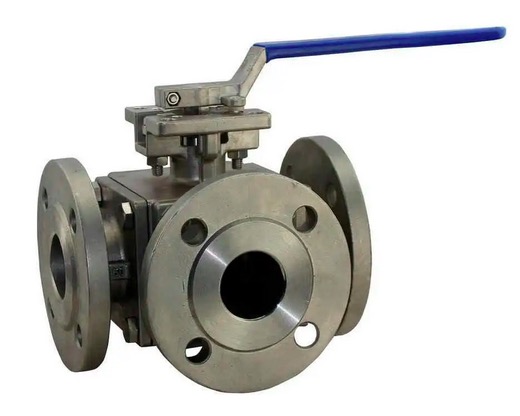

2.3. plug valve and ball valve: the closing part is a plunger or ball which rotates around its own center-line.

2.4. swing type valve: the closing part rotates around the axle pin on the valve seat, like swing check valve, single door swing wafer check valve,etc.

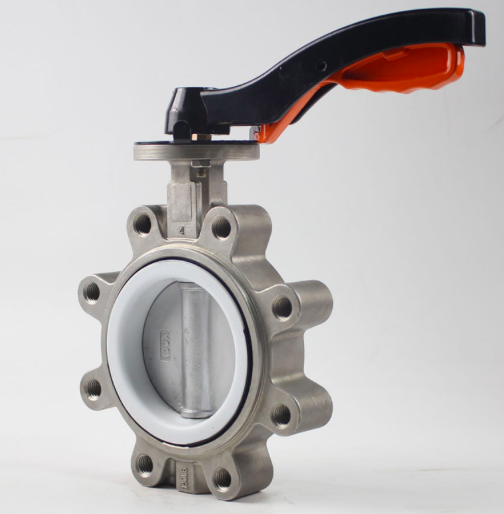

2.5. butterfly valve: the closing disc rotates around the valve stem in the valve seat.

2.6. slide valve: the closing part slides perpendicular to the channel.

3. according to different purpose of valves, it can be divided into:

3.1. to open and close: this kind of valve is used to connect and cut off the mediums, like globe valve, gate valve, ball valve,butterfly valve,etc.

3.2. to prevent flowing back: this kind of valve is used to prevent the back flow of the medium in the plumbing system, like check valve, one way valve, non return valve, back pressure valve, back water valve , foot valve, bottom valve;

3.3. to regulate: this kind of valve is used to regulate the pressure and flow rate of the medium in the plumbing system, like regulating valve, pressure reducing valve;

3.4. to distribute: this kind of valve is used to change the flow direction of the medium and distribute the medium, like three-way plug valve, distribution valve, slide valve,etc.

3.5. safety valve: when the medium pressure exceeds the specified value, the safety valve is used to discharge excess medium to ensure the safety of the plumbing system and equipment, such as safety valve, and emergency valve;

3.6. for some special purpose: such as drain valve, air release valve, sewer valve;

4. According to driving methods, valves can be divided into:

4.1. manual valve: this kind of valve is operated with the help of hand-wheel, handle, lever or chain wheel, driven by man power, when transmitting large torques, there are deceleration devices such as worm gear box, and gears.

4.2. electric valve: this kind of valve is operated by a motor or other electric devices.

4.3. hydraulic valve: this kind of hydraulic valve is driven by water, or oils.

4.4. Pneumatic valve: pneumatic valve is driven by compressed air.

5. According to the nominal pressure, valves can be divided into:

5.1. Vacuum valve: vacuum valve is for the valve with nominal pressure PN<0.1Mpa.

5.2. low pressure valve: Low pressure valve is for those valves whose nominal pressure PN≤1.6Mpa, including steel valve,its PN≤1.6MPa.

5.3. Middle pressure valve: Middle pressure valve is for those valves whose nominal pressure is between PN2.5—6.4MPa.

5.4. high pressure valve: high pressure valve is for those valve whose nominal pressure is between PN10.0—80.0MPa.

5.5. super high pressure valve: super high pressure valve is for those valve whose nominal pressure PN≥100.0MPa.

6. According to the working temperature, valves can be divided into:

6.1. Ordinary valve: ordinary valves can be used for plumbing system with working temperature between -40℃~425℃.

6.2. high temperature valve: high temperature valves can be used in plumbing system with working temperature between 425℃~600℃.

6.3. heat resistant valve: heat resistant valve can be used for plumbing systems with working temperature over 600℃.

6.4. low temperature valve: low temperature valve can be used for plumbing systems with working temperature between -150℃~ -40℃.

6.5. super low temperature valve: super low temperature valve can be used for plumbing systems with working temperature lower than -150℃.

7. According the nominal diameter, valves can be divided into:

7.1. small diameter valves: small diameter valves is for those valves whose nominal diameter DN<40mm.

7.2. middle diameter valves: middle diameter valves is for those valves whose nominal diameter DN50~300mm.

7.3. large diameter valves: large diameter valves is for those valves whose nominal diameter DN350~1200mm.

7.4. super large diameter valves: super large diameter valves is for those valves whose diameter DN≥1400mm.

8. According to the connect method, valves can be divided into:

8.1. flange connection valves: flange connection valves is for those valves whose body has two flanges, and are connected with pipes through flange.

8.2. threaded connection valves: threaded connection valves is for those valves who have internal thread or external thread, those valves are connected with pipes thread those threads.

8.3. welded connection valves: welded connection valves is for those valves who are welded together with pipes.

8.4. grooved connection valves: those grooved valves are connected with pipes with clamps.

8.5. sleeve connection valves: those valves are connected with pipes through sleeves.

What is the characteristics of valves?

There are two characteristics of valves: one is application characteristic and structure characteristic.

1.application characteristics:

It determines the main use performance and use range of valves, the application characteristics have:

1.1. the category of valves (closed valves, regulating valves,safety valves,etc)

1.2. the types of valves( gate valves, globe valves, check valves, butterfly valves, ball valves,etc)

1.3. the material for main components of valve( valve body, bonnet, valve stem, valve disc, sealing surface);

2. structure characteristics:

It determines how to install, repair and maintain the valves, the followings are valves structure characteristics:

2.1. the face to face length of valves, and the height of valves, connect method with pipes( flange connect, threaded connect, grooved connect, external threaded connect, welded connect,etc);

2.2. the type of sealing surface( ring, threaded ring, bead welded, spray welding, valve body itself);

2.3. structural types of valve stem( rotating stem, lifting stem), etc.

How to select the right valves?

1.steps for valve selection:

1.1. clarify the use purpose of the valve in the equipment or device, determine the working conditions of the valve: applicable medium, working pressure, working temperature,etc.

1.2. Determine the nominal diameter and connect method of the pipeline connected to the valve: flange connect, thread connect, welded connect,etc;

1.3. Determine the method to operate the valve: manual, electric, electromagnetic, pneumatic or hydraulic, electro hydraulic linkage,etc.

1.4. According to the medium conveyed by the pipeline, the working pressure and the working temperature, to determine what kind of material should be used for shell body, valve trim: like gray cast iron, malleable cast iron, ductile cast iron, carbon steel, alloy steel, stainless steel, brass alloy,etc.

1.5. what category of valves should be selected: closed valve, regulating valve,safety valve,etc.

1.6. determine the type of valve: gate valve, globe valve, ball valve, butterfly valve, check valve, throttle valve, safety valve, pressure reducing valve, steam drain valve,etc.

1.7. determine the technical parameter: for automatic valves, according to different requirements, determine the allowable flow resistance, discharge capacity, back pressure,etc, and then determine the nominal diameter of the pipeline, and the diameter of the valve seat holes.

1.8. determine the geometric parameters f the selected valve: the face to face length, flange connect standard and size, valve height when the valve is open and closed, connect threaded holes size and quantity, overall valve dimensions,etc.

1.9. using existing material to select the right valve: valve product catalogs, valve samples.

2. why some valve is selected:

After grasping the steps to select a valve, now we should learn why some kind of valve should be used?

2.1. the purpose of the selected valve, operating conditions and operating methods.

2.2. the nature of the working medium: working pressure, working temperature, corrosive properties, whether the medium contains solid particles, whether the medium is toxic, whether the medium is flammable or explosive, the viscosity of the medium,etc.

2.3. requirements for valve fluid characteristics: flow resistance, discharge capacity, flow characteristics, sealing level,etc.

2.4. Installation size and external size requirements: nominal diameter, connection method, and connection size with the pipeline, external size or weight limit,etc.

2.5. additional requirements for valve product reliability, service life and explosion proof performance of electric devices.

If the valve is to be used for control purpose, the following additional parameters must be determined: operating method, maximum and minimum flow requirements, pressure drop for nominal flow, pressure drop at closing, maximum and minimum inlet pressure for the valve.

According to the above mentioned basis and steps for how to select a right valve, when selecting a valve reasonably and correctly, it is necessary to have a detailed understanding about the internal structures of various types of valves, so that a correct choice can be made for the preferred valve.

The final control of the pipeline is the valve. The valve’s opening and closing part controls the flow of the medium in the pipeline. The shape of the valve flow channel makes the valve have certain flow characteristics, which must be considered when selecting the most suitable valve for the plumbing system.

Principles for selecting a proper valve:

1. valves used to connect and cut off the medium:

For the valve, whose flow channel is a straight through, its flow resistance is small, those valve is usually used to connect and cut off the medium.

For downward closed valve, like stop valve/globe valve, plug valve, its flow channel is tortuous, and flow resistance is higher than other valves, so this kind of valve is rarely used. Closed valves can be used in the occasion where higher flow resistance is allowed.

2. valve used to regulate the flow rate:

Usually, the valve that is easy to adjust the flow rate is selected to control flow. Downward closed valves(like globe valve) are suitable for this purpose, because of the proportional relationship between the size of the valve seat and the stroke of the closing part. Rotating type valve(plug valve, butterfly valve, ball valve) and flexible body valves(pinch valves, diaphragm valves) can also be used for throttling control , but usually used within a limited range of valve sizes.

The gate valve uses the disc-shaped plate to make a transverse movement to the circular valve seat. Gate valve can control the flow well only when it is close to the closed position, so gate valve is usually not used for flow control.

3. valves used to change the direction and distribute the flow:

For the requirements to change the direction and distribute the flow, this kind of valve may have three or more passages. Plug valves and ball valves are more suitable for this purpose, so most of the valves used to changing the direction and distributing the flow are selected from one of these types of valves. But in some cases, other types of valves can also be used for changing the direction and distributing the flow, as long as two or more valves are properly connected to each other.

4. Valves used for medium with suspended particles:

Where there are suspended particles in the medium, it is most suitable to select a valve whose closing part slides along the sealing surface with a wiping effect. If the back and forth movement of the closing part to the valve seat is vertical, particles may be trapped, so this valve is only suitable for basically clean mediums unless the sealing face material can allow the embedded particles. The ball valves and plug valves have a wiping effect on the sealing surface during the opening and closing process, so plug valves and ball valves are suitable for medium with suspended particles.

for more articles related, please visit:

- How do you purchase a proper industrial valve?

- What is a wafer butterfly check valve?

- What is the difference between a wafer check valve and a swing check valve?

- Can wafer check valve be installed vertically or horizontally?

- What is foot valve?

- What does a foot valve do?

- What is the difference between check valve and globe valve?

- What is a ball type check valve?

- How ball type check valve works?

- What is multi function check valve?

- What is a silent check valve or silencing check valve?

- What is a vertical lift check valve?

- How to select a proper industrial valve for my water supply and drainage pipeline systems?

- what is a rubber disc check valve?

- What is the difference between rubber disc check valve and swing check valve?

- What is cast steel on valves? Like WCB butterfly valves, WCB check valves, WCB gate valves….

- how to choose a right check valve?