Check valve refers to a valve whose opening and closing part is a circular disc and acts by its own weight and medium pressure to block the back flow of the medium, also called back water valve, back pressure valve, cut off valve, non return valve, isolation valve, is one kind of automatic industrial valves which is used in water pump system, or other water supplying systems to prevent the back flow of the mediums.

Types of check valve:

The valve which opens or closes itself by the force of the medium flow to prevent the back flow of the medium is called a check valve. The check valve belongs to the automatic valve, which is mainly used in the pipeline where the medium flows in one direction, and only allows the medium to flow in one direction to prevent accidents.

1. According to different structure, check valve can be divided into three types: lift check valve, swing check valve and wafer butterfly type check valve.

-lift check valve can be divided into vertical lifting check valve and horizontal lifting check valve.

-the swing check valve is divided into three types: single door swing check valve, double door swing check valve, multiple door swing type check valve.

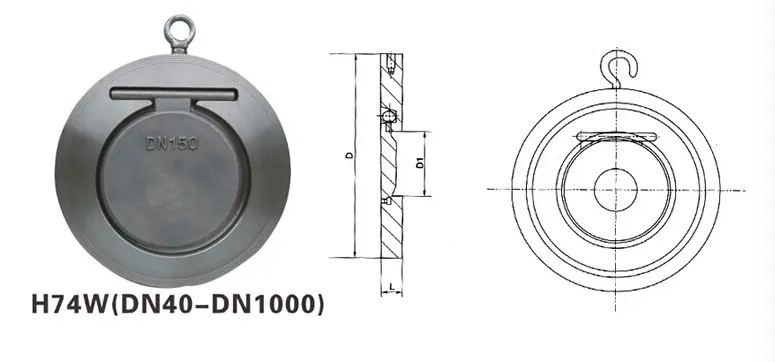

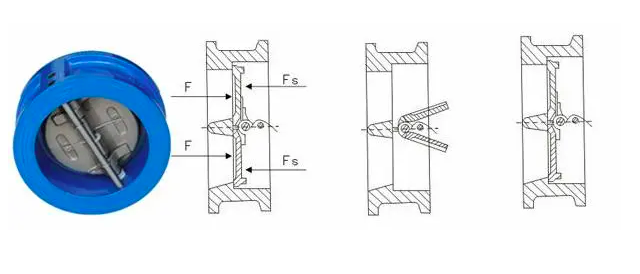

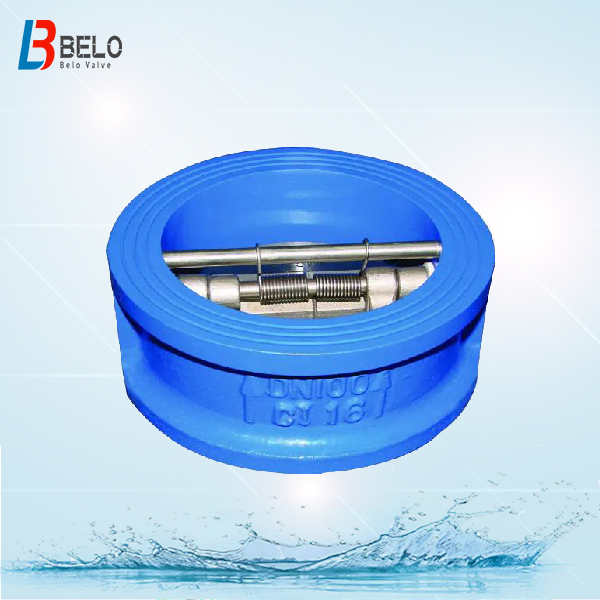

-the wafer butterfly type check valve is one kind of straight through type check valve.

According to end connection, those check valves above can be divided into threaded connection, flange connection, welded connection and wafer connection;

2. According to different material, check valve can be divided into:

-cast iron check valve

-brass check valve

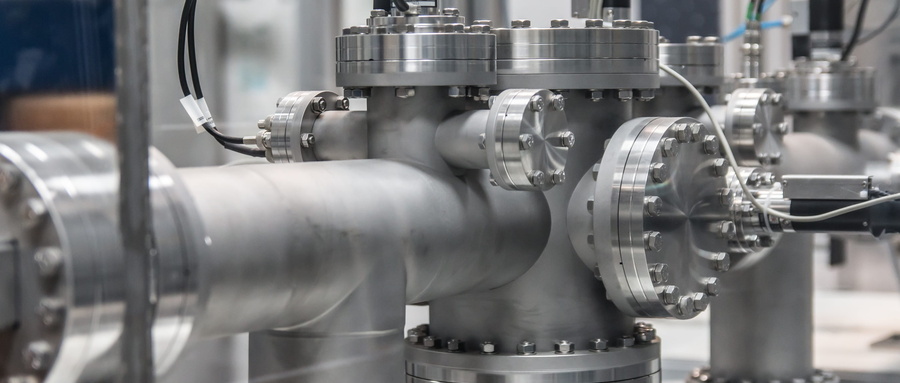

-stainless steel check valve

-carbon steel check valve

-forged steel check valve

3. According to different function, check valve can be divided into:

-DRVZ silencing check valve

-DRVG silencing check valve

-NRVR silencing check valve

-SFCV rubber disc check valve

-DDCV double door check valve

How to select check valve:

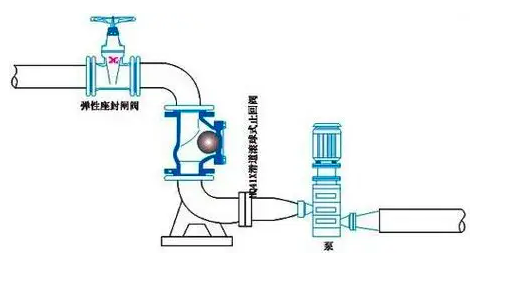

1. in order to prevent the back flow of the medium, check valve should be installed on the equipment, devices and pipeline;

2. The check valve is generally suitable for clean medium, not suitable for medium containing solid particles and high viscosity;

3. Generally, for horizontal pipes with a nominal diameter of 50mm, horizontal lift check valves should be used.

4. Straight through lift check valve can only be installed on horizontal pipelines;

5. For the water pump inlet pipeline, the bottom valve is used, bottom valve is generally only installed on the vertical pipeline of the pump inlet, and the medium flows from bottom to the top;

6. Compared with swing check valve, lifting check valve has better sealing performance and larger fluid resistance. The horizontal type lifting check valve should be installed on the horizontal pipeline, and the vertical type lifting check valve should be installed on the vertical pipeline;

7. There is no limit for the installation position of the swing check valve. Swing check valve can be installed on horizontal, vertical or inclined pipelines. If swing check valve is installed on a vertical pipeline, the flow direction of the medium should flow from the bottom to the top;

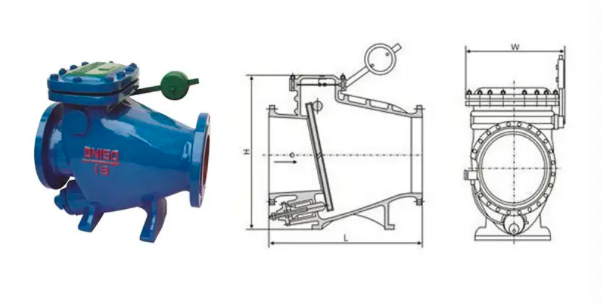

8. the swing check valve should not be made into a small diameter valve, but swing check valve can be made into a very high working pressure valve, the nominal pressure can reach 42Mpa, and also the nominal diameter can be very large, the maximum nominal diameter of swing check valve can be 2000mm. With different material used for shell body and sealing part, swing check valve can be applied to any working mediums and any working temperatures. The working mediums of swing check valve can be water, steam, gas, corrosive medium, oils and medicines,etc. The working temperature of swing check valve can be between -196℃~800℃。

9. The swing check valve is suitable for low pressure but large diameter pipelines, and also the installation situation of swing check valve is limited;

10. There is no limit for the installation of wafer butterfly type check valve, butterfly type check valve can be installed on the horizontal pipeline, or vertical, or inclined pipelines.

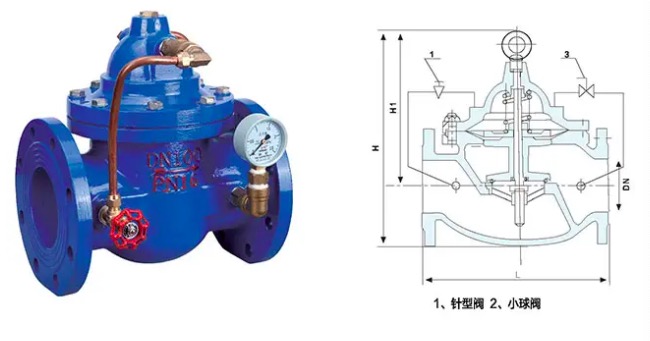

11. Diaphragm check valve is suitable for pipelines that are prone to water hammer. The diaphragm can well eliminate the water hammer caused by the reverse flow of the medium. It is generally used in low pressure and nominal temperature pipelines, especially for tap water pipelines. Generally, the working temperature of the medium is between -12–120℃, the working pressure is less than 1.6Mpa, but the diaphragm check valve can achieve a larger diameter, and the maximum DN can reach more than 2000mm.

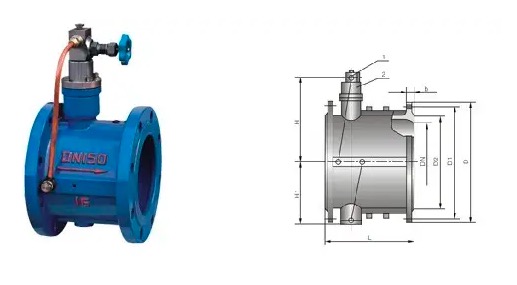

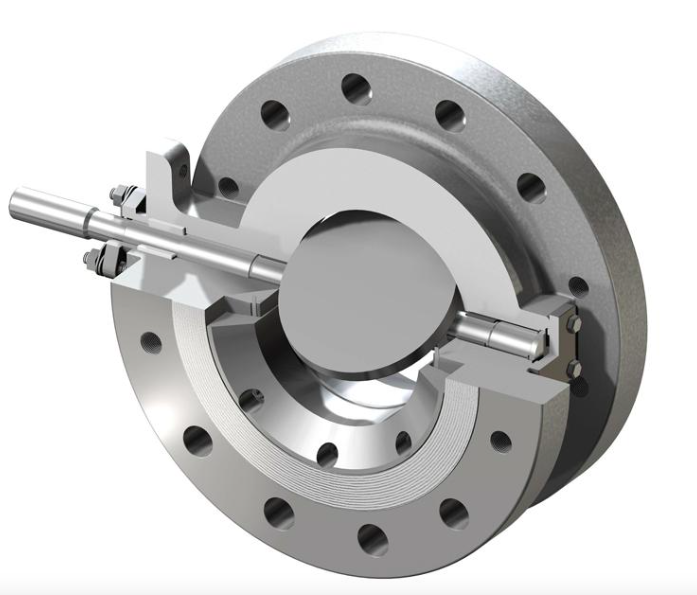

12. The ball type check valve is suitable for medium and low pressure pipelines and can be made into large diameter valves;

13. The shell material of the ball type check valve can be made of stainless steel, and the hollow sphere of the sealing item can be wrapped with PTFE engineering plastic, so ball type check valve can also be used in the pipeline of general corrosive medium, and the working temperature of ball type check valve is between -101–150℃. the nominal pressure of ball type check valve is less than or equal to 4.0Mpa, and the nominal diameter of ball type check valve is between DN200-DN1200;

14. When selecting a check valve for incompressible fluids, the first step is to evaluate the required closing speed, and the second step is to select the type of check valve which may meet the required closing speed;

15. The selection of check valves for compressible fluids can be made according to a similar method of selection of check valve for incompressible fluids. If the flow range of the medium is large, the check valve for compressible fluids can use a deceleration device, if the medium flow is stopped and started quickly without a break, like the outlet of a compressor,a lift check valve should be used;

16. the corresponding size of the check valve should be determined, the valve supplier must provide the data of the selected size, so that the valve size can be found when the valve is fully opened at a given flow rate;

17. For high and medium pressure check valve with nominal diameter below DN50mm, vertical lifting check valve and straight through lifting check valve should be used;

18. For low pressure check valve with nominal diameter below DN50mm, wafer butterfly type check valve, vertical lift check valve and diaphragm type check valve should be used;

19. For high and medium pressure check valve with nominal diameter between DN50mm-DN600mm, the swing check valve should be used;

20. For medium and low pressure check valve with nominal diameter between DN200-DN1200mm, the non-wear ball type check valve should be selected;

21. For low pressure check valve with nominal diameter between DN50nn-DN2000mm, butterfly type check valve and diaphragm type check valve should be used;

22. For pipelines which require less water hammer or no water hammer when closed, slow closing type swing check valve and slow-closing butterfly type check valve should be used;

How to install check valve:

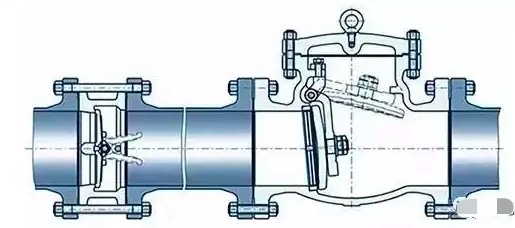

1. for swing check valve: the plate of the swing check valve is disc-shaped and rotates around the shaft of the valve seat passage; because the passage in the swing check valve is streamlined, the flow resistance in the swing check valve is smaller than that of the lift check valve. Swing check valve is suitable for pipelines which have large diameter, with low flow rate and its flow rate won’t change too frequently. Swing check valve is not suitable for pulsating flow, and the sealing performance of swing check valve is not as good as the lifting type check valve. According to the valve’s diameter, swing check valve can be divided into single door swing check valve, double door swing check valve and multiple door swing check valve. Their purpose is to reduce the hydraulic shock when the medium stops flowing or flows back.

2. For lift check valve: lift check valve is one kind of check valve whose disc slides along the vertical center line of the valve body. Lifting check valves can only be installed on horizontal pipelines. For high pressure small diameter check valves, the disc can be made of balls. The shape of the valve body of the lift check valve is the same as that of the globe valve(lift check valve can be used in common with the globe valve), so the fluid resistance coefficient is larger. The structure of lift check valve is similar to the globe valve, and the valve body and disc are the same as the globe valve. The upper part of the valve disc and the lower part of the bonnet are machined with guide sleeves. The valve disc guide can be freely lifted and lowered in the valve guide. When the medium flows downstream, the valve disc is opened by the thrust of the medium; the valve disc falls vertically on the valve seat to prevent the reverse flow of the medium. The direction of the medium inlet and outlet channels of the straight through lift check valve is perpendicular to the direction of the valve seat channel; the direction of the medium inlet and outlet channels in vertical lift check valve are same as the valve seat channel, and the flow resistance in vertical lift check valve is smaller than that in the straight through type lift check valve;

3. Wafer butterfly type check valve: butterfly type check valve is one kind of valve whose disc rotates around the pin shaft in the valve seat. The butterfly type check valve has a simple structure and can only be installed on horizontal pipeline, and the sealing performance of butterfly type check valve is poor;

4. lifting type vertical flap check valve should be installed on vertical pipes;

5. the lifting type horizontal flap check valve should be installed on the horizontal pipeline;