Foot valve is also known as bottom valve, well bottom valve, well check valve, water pump check valve, etc, which is actually one kind of check valve. Foot valve is usually at the bottom of the water pump to prevent the back flow of the water.

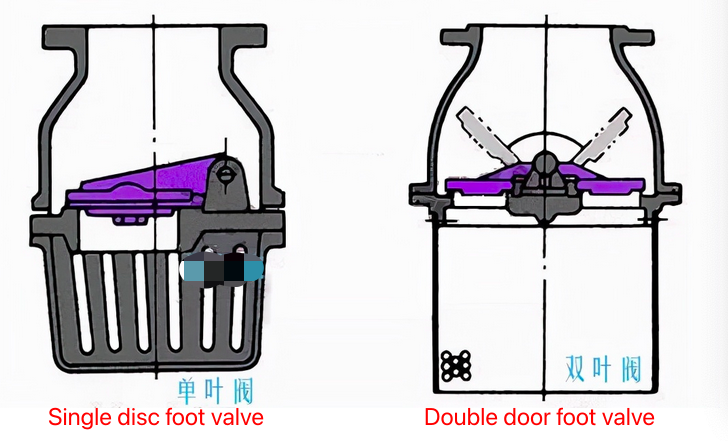

Foot valve is composed of valve body, valve disc, bonnet, sealing ring, gasket and other parts. Foot valve has single disc foot, dual disc foot valve and multi disc foot valve.

According to material used, foot valve has metal foot valve and plastic foot valve. Foot valve can also be divided into ordinary foot valve and foot valve with backwash water flow. Foot valve is mainly used in water pumps and other mechanical equipment for handling slurry. Usually, the foot valve is installed at the bottom of the underwater suction pipe of the pump to prevent the back flow of the slurry.

What is the structure of foot valve?

The foot valve has multiple water inlets on the bonnet, and is equipped with a screen to reduce the inflow of debris and reduce the probability of blocking the foot valve. Although the foot valve is equipped with an anti-clogging screen, the foot valve is generally suitable for cleaning media, and the medium with excessive viscosity and particles should not use the foot valve.

Advantage of foot valve:

- the structure of foot valve is ideal in terms of flow and manufacturing process requirements, and also the foot valve will not produce turbulent flow during emptying.

- Belo Valve can supply all international connect foot valves, like welded foot valve, grooved foot valve and threaded foot valve.

- The foot valve material can be SS304, SS316, SS316L, of course, other alloy steels can be used according to customer requirements.

- The surface of the foot valve can be mechanically polished or electro polished according to customer requirements, and the accuracy can reach 0.25um.

- The foot valve can be equipped with manual and pneumatic actuator.

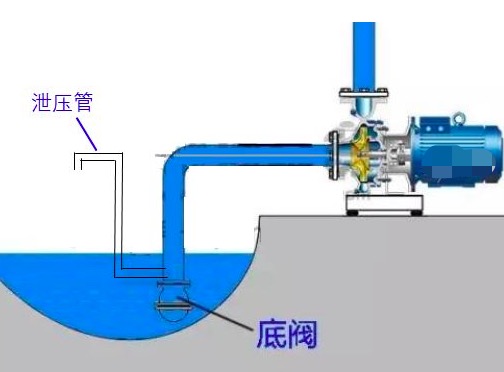

Each water pump needs to be installed with a foot valve. The foot valve is usually installed below the water surface, while the above-water foot valve is installed above the water surface. It is a replacement product of the old-fashioned foot valve, is the ideal water diversion equipment, and can also replace vacuum pump and vacuum device.

The foot valve has reasonable design, advanced manufacturing technology, and convenient installation, simple and easy to use and maintain. Also it has the advantages of low friction resistance, long service life, energy-saving,etc. Foot valve is widely used in supporting facilities for sump pump in petrochemical, chemical, textile, printing and dyeing, metallurgy,mining,irrigation and other industries.

Installation of foot valve:

- First, remove the wooden support in the valve body of the foot valve before installation, otherwise the foot valve could not work.

- Foot valve is installed at the bottom of the suction pipe of the water pump, and the foot valve should be installed vertically.

- Start-up: before the first start, the forward water pipe should be filled with water and start immediately, to make a semi-vacuum state in the suction pipe, and the water is sucked into the vertical pipe to complete the pumping process.

- Maintenance: In general, No maintenance is required. When maintenance is required, just open the middle port of the foot valve, and replace the rubber gasket of the foot valve.

- If the foot valve is used in a fluid with high acid-base concentration, you should choose a stainless steel water type foot valve, and also other material can be used for foot valve.

What are the symptoms of a bad foot valve and how to fix a bad foot valve?

1. Symptom of a bad foot valve: the water pump cannot deliver water.

Why the foot valve is bad: Check whether the support part of the foot valve is removed;

How to fix the bad foot valve: remove the support wood inside the valve body;

2. why the foot valve is bad: check whether there is air leakage at the interface of the water diversion pipe;

How to fix the bad foot valve: sealing the pipe interface;

3. Why the foot valve is bad: whether the water pipe is filled with water before the pump is turned on;

How to fix the bad foot valve: fill the pipes with water before starting the pump.

4. Why the foot valve is bad: check whether the water pump is reversed;

How to fix a bad foot valve: connect the wires properly.

5. Why the foot valve is bad: check whether the water pump has air leakage, or whether the water pump is damaged.

How to fix a bad foot valve: repair or replace the water pump.

Technical parameter for foot valve:

Nominal Diameter of foot valve(DN): DN15-DN350

Nominal Pressure of foot valve(PN): PN0.25Mpa.

Applicable medium: water, oils and non corrosive mediums.

Manufacturing standard: Q/12 NJ3583-2001

Testing standard: GB/T13927-1992

For more information about other industrial valves, go to:

- How do i know which industrial valve to use?

- How to select a right check valve according to diameter?

- what are the common used types of check valve?

- How do i choose a check valve?

- how to choose a right check valve?

- What is cast steel on valves? Like WCB butterfly valves, WCB check valves, WCB gate valves….

- What is the difference between cast steel valves and forged steel valves?

- What is forged steel valve?

- What does those model No. Mean for check valves, like H76,H42, HC44, H44, H61Y,etc…

- what is a rubber disc check valve?

- what is a swing check valve?

- What is the advantage of ball type check valve?

- How to install a lift check valve?

- What is the difference between check valve and globe valve?

- What is the advantage and disadvantage of a globe valve?

- Can a foot valve be installed horizontally or vertically?

- What is a bottom valve?

- How do foot valves work?

- Is foot valve required for self priming pump?

- Do submersible pumps have foot valves?