Industrial valve is a mechanical equipment that is a very important necessary part in pipeline systems, and is used to connect, cut off and regulate the medium flows. With different material used for different valves like ductile cast iron, WCB, stainless steel, cast iron, forged steel, different industrial valves can be used for different mediums, like waters, steam, oils, gas, acid mediums, corrosive mediums, etc. Today we are going to discuss the instructions for how to select a right industrial valve for our projects. gate valve, globe valve, ball valve, throttle valve, plug valve, butterfly valve, check valve, diaphragm valve, which one is the appropriate valve for our pipelines:

1. How to choose a gate valve:

Generally, gate valves should be selected first. In addition to being suitable for steam, oil and water and other mediums, gate valves are also suitable for medium containing granular solids and high viscosity, and are suitable for venting and low vacuum systems. For medium with solid particles, the gate valve body should have one or two purge holes. For low temperature medium, special gate valve for low temperature should be selected.

2. How to choose a globe valve:

The globe valve is suitable for pipelines which do not have strict requirements on fluid resistance, that is, the pressure loss is not considered, and for the pipelines or devices of high temperature and high pressure medium, globe valve is suitable for pipelines with nominal diameter DN<200mm of steam and other mediums; small diameter valve can choose globe valves, such as needle valve, gauge valve, sample valve, pressure gauge valve,etc; Globe valves have flow adjustment or pressure adjustment, but the requirements for adjustment accuracy are not high, and when the diameter of the pipeline is relatively small, the globe valve or throttling valve should be selected; For highly toxic medium, a bellows-sealed globe valve should be used; but the globe valve should not be used for medium with high viscosity and medium containing particles which are easy to precipitate, nor should it be used as a vent valve and a valve for a low vacuum system.

3. Instruction for how to select a ball valve:

Ball valve is suitable for low temperature, high pressure and high viscosity mediums. Most of the ball valves can be used in medium with suspended solid particles, and can also be used for powder and granular medium according to the requirements of sealing materials; Full port ball valves are not suitable for flow regulation, but are suitable for occasions which requires rapid opening and closing, which is easy to achieve emergency cut-off for accidents; Usually in pipelines with strict sealing performance, wear,shrinking channels, rapid opening and closing actions, high pressure cut-off(large pressure difference),low noise, gasification, small operation torque, and small fluid resistance, ball valves are recommended to use.

The ball valve is suitable for light structure, low pressure cut-off and corrosive mediums; the ball valve is also the most ideal valve for low temperature and cryogenic medium, for the pipeline system and device of low temperature medium, the low temperature ball valve with bonnet should be selected; When selecting the floating ball valve, its seat material should bear the load of ball bod and the working medium. Large diameter ball valves require greater force during operation, ball valve with DN≥200mm should use the worm gear box for driving; the trunnion mounted ball valves are suitable for larger diameter and higher pressure pipelines. In addition, the ball valves used in the pipelines of highly toxic material and flammable medium should have a fireproof and anti-static structure.

4. Guideline for throttle valve selection:

The throttle valve is suitable for the occasions where the medium temperature is low and the pressure is high, and it is suitable for the parts where the flow and pressure need to be adjusted. Throttling valve is not suitable for medium with high viscosity and solid particles, and it is not suitable to work as a isolation valve.

5. Plug valve selection instructions:

The plug valve is suitable for occasions requiring rapid opening and closing, generally not suitable for steam and high temperature mediums. Plug valve is suitable for low temperature, high viscosity medium, and also for medium with suspended particles.

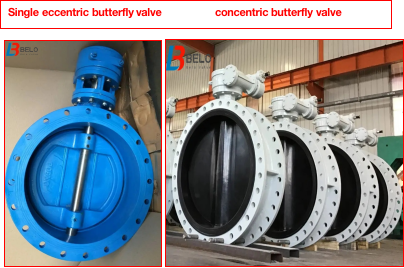

6. Instruction for how to select a butterfly valve:

Butterfly valve is suitable for occasions with large diameter(such as DN﹥600mm) and short structure length, as well as the need for flow adjustment and fast opening and closing. Butterfly valve is used for medium like water, oils, and compressed air and other mediums with temperature ≤80℃, pressure ≤1.0MPa. Compared with gate valve and ball valve, the pressure loss for butterfly valve is larger, so butterfly valve is suitable for pipeline systems where pressure loss requirements are not strict.

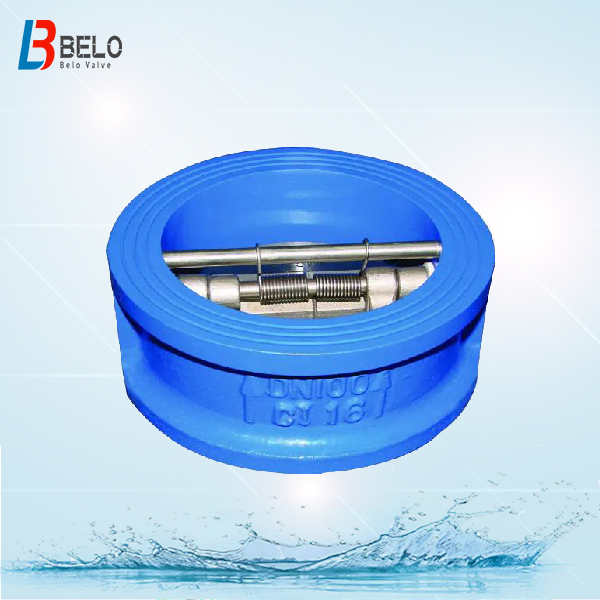

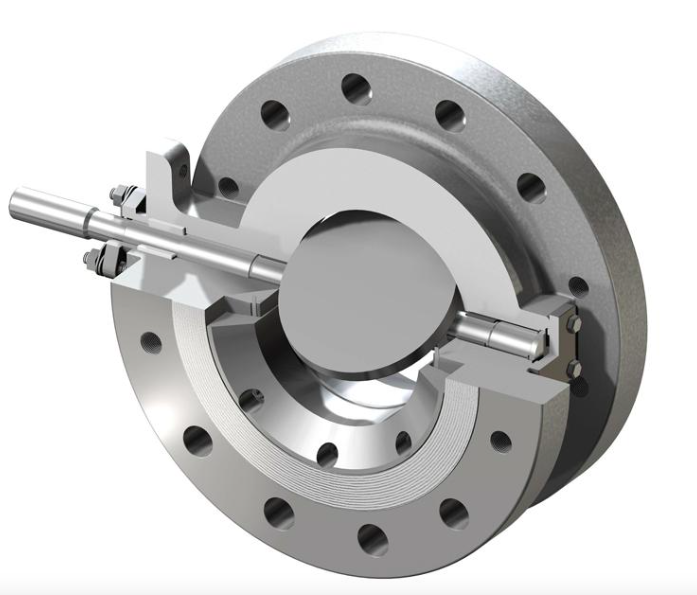

7. Check valve selection instructions:

Check valve is generally suitable for clean medium, and should not be used for media containing solid particles and high viscosity.

When diameter is ≤40mm, lifting type check valve should be used( lift check valve can be only installed on horizontal pipelines);

When the DN=50~400mm, swing type lifting check valve should be used,(swing type lifting check valve can be installed on vertical and horizontal pipelines,if swing type lifting check valve is installed on vertical pipelines, the medium should flow from bottom to top);

When DN≥450mm, the buffer type check valve should be used;

When DN=100~400mm, wafer type check valve can be used;

Swing type check valve can be made into high pressure ones, Its PN can reach 42Mpa. According to the different materials of the valve body and sealing surface, swing check valve can be used for any working medium and any working temperature, its applicable medium can be water, steam, gas, corrosive medium, oils, medicines,etc, and the working temperature can range from -196~800℃.

8. How to select a diaphragm valve:

Diaphragm valve is suitable for oils, water, acid medium and medium containing suspended solids with working temperature less than 200℃, and pressure less than 1.0Mpa. Diaphragm valve is not suitable for organic solvent and strong oxidant medium; weir diaphragm valve should be selected for abrasive particle medium. The selection of the weir diaphragm valve should refer to its flow characteristics table; the straight through diaphragm valve should be used for viscous fluid, cement slurry and precipitating medium; Except for special requirements, the diaphragm valve should not be used in vacuum pipelines and vacuum equipment.

If you want to know what kind of industrial valves should be used in your projects, kindly contact us: we can give you professional advice according to the real working conditions;

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

For other articles about industrial valves:

- How do i know which industrial valve to use?

- How to select a right check valve according to diameter?

- what are the common used types of check valve?

- How do i choose a check valve?

- how to choose a right check valve?

- What is cast steel on valves? Like WCB butterfly valves, WCB check valves, WCB gate valves….

- What is the difference between cast steel valves and forged steel valves?

- What is forged steel valve?

- What does those model No. Mean for check valves, like H76,H42, HC44, H44, H61Y,etc…

- what is a rubber disc check valve?

- what is a swing check valve?

- What is the advantage of ball type check valve?

- How to install a lift check valve?

- What is the difference between check valve and globe valve?

- What is the advantage and disadvantage of a globe valve?